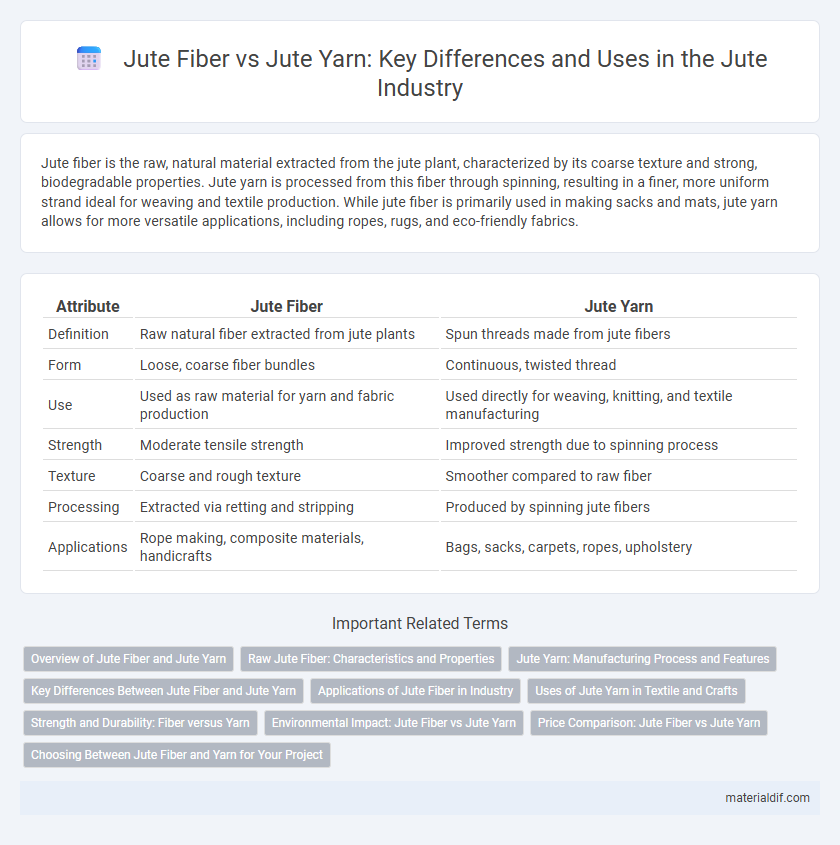

Jute fiber is the raw, natural material extracted from the jute plant, characterized by its coarse texture and strong, biodegradable properties. Jute yarn is processed from this fiber through spinning, resulting in a finer, more uniform strand ideal for weaving and textile production. While jute fiber is primarily used in making sacks and mats, jute yarn allows for more versatile applications, including ropes, rugs, and eco-friendly fabrics.

Table of Comparison

| Attribute | Jute Fiber | Jute Yarn |

|---|---|---|

| Definition | Raw natural fiber extracted from jute plants | Spun threads made from jute fibers |

| Form | Loose, coarse fiber bundles | Continuous, twisted thread |

| Use | Used as raw material for yarn and fabric production | Used directly for weaving, knitting, and textile manufacturing |

| Strength | Moderate tensile strength | Improved strength due to spinning process |

| Texture | Coarse and rough texture | Smoother compared to raw fiber |

| Processing | Extracted via retting and stripping | Produced by spinning jute fibers |

| Applications | Rope making, composite materials, handicrafts | Bags, sacks, carpets, ropes, upholstery |

Overview of Jute Fiber and Jute Yarn

Jute fiber is a natural, long, soft, and shiny vegetable fiber primarily obtained from the Corchorus plant, extensively used in making textiles, ropes, and sacks due to its strength and durability. Jute yarn is spun from jute fibers and serves as a basic raw material in the textile industry, influencing fabric texture and quality with variations in thickness and twist. Both jute fiber and jute yarn are biodegradable and eco-friendly, playing a crucial role in sustainable textile production and environmentally conscious manufacturing practices.

Raw Jute Fiber: Characteristics and Properties

Raw jute fiber exhibits natural golden color, high tensile strength, and excellent moisture regain, making it ideal for eco-friendly textile applications. Its coarse texture and long staple length distinguish it from processed jute yarn, which is spun and refined for smoother, more uniform threads. The fiber's biodegradability and thermal insulation properties enhance its suitability for packaging, upholstery, and composite materials.

Jute Yarn: Manufacturing Process and Features

Jute yarn is produced by spinning natural jute fibers, which are extracted from the jute plant's bark through a retting process that loosens the fibers. The manufacturing process involves cleaning, carding, and combing the fibers before spinning them into yarn using ring or mule spinning techniques. Jute yarn is characterized by its strength, durability, biodegradability, and versatility, making it suitable for producing eco-friendly textiles, bags, ropes, and upholstery.

Key Differences Between Jute Fiber and Jute Yarn

Jute fiber is the raw natural fiber obtained from the stem of the jute plant, characterized by its coarse, long, and shiny strands, primarily used for making ropes, sacks, and mats. Jute yarn, on the other hand, is a refined form of jute fiber that has been spun into threads or strands suitable for weaving and knitting, providing greater strength and flexibility for textile products. The key difference lies in processing and application: jute fiber is the unprocessed material, while jute yarn is the processed, spun form used in fabric production.

Applications of Jute Fiber in Industry

Jute fiber's coarse, strong natural texture makes it ideal for industrial applications such as carpet backing, geo-textiles, and sackcloth, where durability and breathability are crucial. Unlike finer jute yarn used in textiles, raw jute fiber retains high tensile strength, enabling its use in heavy-duty packaging and erosion control mats. These properties position jute fiber as an eco-friendly alternative to synthetic fibers in agriculture, construction, and furniture manufacturing.

Uses of Jute Yarn in Textile and Crafts

Jute yarn is widely used in the textile industry for producing eco-friendly fabrics, hessian cloth, and shopping bags due to its durability and natural luster. In crafts, jute yarn serves as a popular material for making rugs, mats, wall hangings, and decorative items, leveraging its strength and rustic texture. Unlike raw jute fiber, jute yarn is spun and refined, offering enhanced versatility and ease of use in weaving and knitting applications.

Strength and Durability: Fiber versus Yarn

Jute fiber exhibits natural tensile strength and resilience essential for producing durable materials, while jute yarn, spun from multiple fibers, enhances overall strength and durability through increased uniformity and compactness. The mechanical properties of jute yarn improve resistance to wear and tear, making it suitable for heavy-duty applications such as sacks and ropes. Strength in jute yarn depends on fiber quality, twist level, and processing methods, resulting in greater durability compared to raw jute fiber.

Environmental Impact: Jute Fiber vs Jute Yarn

Jute fiber, being the raw material, requires minimal processing, resulting in a lower environmental footprint compared to jute yarn, which undergoes spinning and sometimes chemical treatments that increase energy consumption and emissions. The biodegradability of jute fiber ensures efficient natural decomposition, whereas jute yarn's processing can introduce slight delays in ecological breakdown depending on added treatments. Overall, selecting jute fiber over jute yarn reduces carbon emissions and water usage, making it a more sustainable option in eco-friendly textile production.

Price Comparison: Jute Fiber vs Jute Yarn

Jute fiber is generally less expensive than jute yarn due to minimal processing requirements, making it a cost-effective raw material. Jute yarn, which undergoes additional spinning and refining processes, commands a higher price reflecting the labor and machinery involved. The price difference between jute fiber and jute yarn is significant in industries focusing on cost optimization and product quality.

Choosing Between Jute Fiber and Yarn for Your Project

Jute fiber offers a coarse texture and high tensile strength, making it ideal for robust, eco-friendly applications such as sacks, ropes, and mats. Jute yarn, spun from the fiber, provides greater flexibility and smoothness suited for weaving finer textiles, upholstery, and decorative crafts. Selecting between jute fiber and yarn depends on the desired durability, texture, and application requirements of your project.

Jute fiber vs Jute yarn Infographic

materialdif.com

materialdif.com