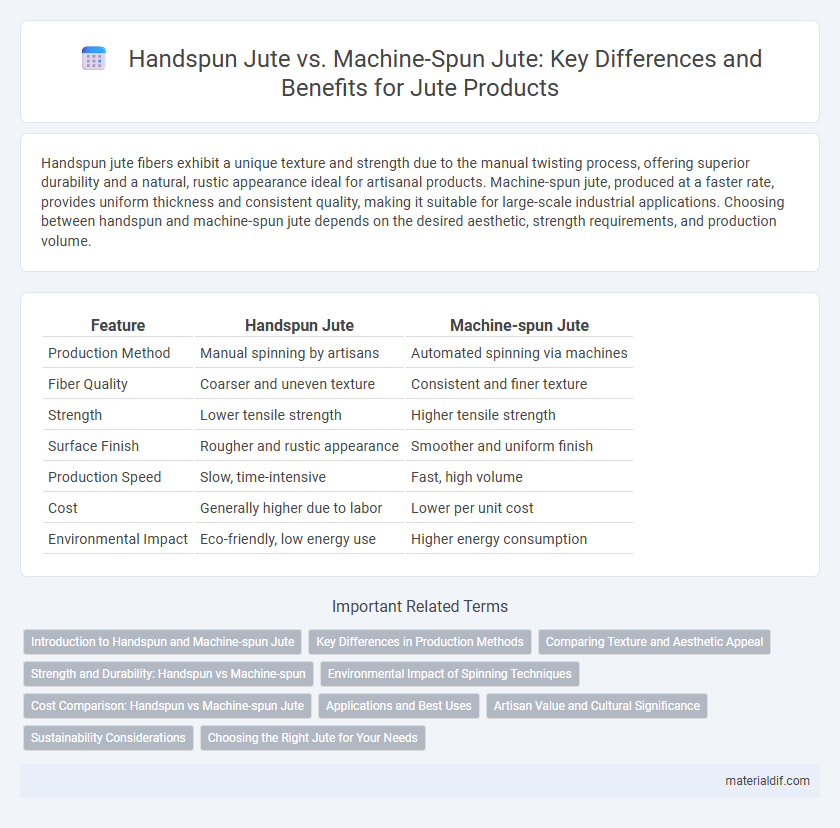

Handspun jute fibers exhibit a unique texture and strength due to the manual twisting process, offering superior durability and a natural, rustic appearance ideal for artisanal products. Machine-spun jute, produced at a faster rate, provides uniform thickness and consistent quality, making it suitable for large-scale industrial applications. Choosing between handspun and machine-spun jute depends on the desired aesthetic, strength requirements, and production volume.

Table of Comparison

| Feature | Handspun Jute | Machine-spun Jute |

|---|---|---|

| Production Method | Manual spinning by artisans | Automated spinning via machines |

| Fiber Quality | Coarser and uneven texture | Consistent and finer texture |

| Strength | Lower tensile strength | Higher tensile strength |

| Surface Finish | Rougher and rustic appearance | Smoother and uniform finish |

| Production Speed | Slow, time-intensive | Fast, high volume |

| Cost | Generally higher due to labor | Lower per unit cost |

| Environmental Impact | Eco-friendly, low energy use | Higher energy consumption |

Introduction to Handspun and Machine-spun Jute

Handspun jute is crafted by artisans using traditional spinning wheels, producing fibers with a coarse texture and unique natural variations that enhance its rustic appeal. Machine-spun jute is manufactured through mechanized processes, enabling consistent thread thickness and higher production volumes suitable for industrial applications. The choice between handspun and machine-spun jute impacts the final product's texture, durability, and aesthetic qualities in textiles and eco-friendly packaging.

Key Differences in Production Methods

Handspun jute involves manual fiber twisting using traditional tools, resulting in uneven texture and lower production speed. Machine-spun jute employs automated spinning technology that ensures uniform thread quality and higher efficiency. The choice between the two affects durability, texture, and application in various textile products.

Comparing Texture and Aesthetic Appeal

Handspun jute features a coarser, uneven texture that enhances its rustic and artisanal aesthetic, often preferred for decorative items and traditional crafts. Machine-spun jute offers a smoother, more uniform finish, making it ideal for industrial applications requiring consistent strength and appearance. The choice between handspun and machine-spun jute depends on the desired tactile quality and visual appeal for specific uses.

Strength and Durability: Handspun vs Machine-spun

Handspun jute fibers exhibit higher tensile strength and enhanced durability due to the careful manual processing that preserves fiber integrity. Machine-spun jute often has uniform thickness but may suffer from micro-tears and uneven tension, reducing overall strength. The artisanal approach in handspun jute results in longer-lasting, more resilient fabric compared to its machine-spun counterpart.

Environmental Impact of Spinning Techniques

Handspun jute requires minimal energy consumption, relying on manual labor, which significantly reduces its carbon footprint compared to machine-spun jute that depends heavily on electricity and fossil fuels. The traditional handspinning process produces negligible industrial waste and pollutants, whereas machine-spun jute often involves chemical treatments and generates more environmental pollutants during production. Opting for handspun jute supports sustainable practices by minimizing resource use and maintaining ecological balance.

Cost Comparison: Handspun vs Machine-spun Jute

Handspun jute typically incurs higher production costs due to labor-intensive processes and slower output, resulting in a premium price point compared to machine-spun jute. Machine-spun jute benefits from automation and increased efficiency, leading to lower manufacturing expenses and more competitive market pricing. Cost differences also reflect variations in quality, durability, and application suitability between handspun and machine-spun jute fibers.

Applications and Best Uses

Handspun jute offers superior strength and texture, making it ideal for artisanal crafts, traditional textiles, and eco-friendly packaging that require durability and a rustic appearance. Machine-spun jute excels in large-scale industrial applications such as carpet backing, upholstery, and geotextiles due to its consistent quality and higher production efficiency. Choosing between handspun and machine-spun jute depends on the application's demand for aesthetic authenticity versus mass production and uniformity.

Artisan Value and Cultural Significance

Handspun jute embodies artisan value through its meticulous, traditional weaving techniques passed down generations, creating unique textures and reinforcing cultural heritage. Machine-spun jute prioritizes uniformity and large-scale production, often lacking the nuanced craftsmanship and legacy intrinsic to handspun fibers. The cultural significance of handspun jute lies in preserving artisanal skills and supporting local economies, fostering a deep connection between the material and its regional identity.

Sustainability Considerations

Handspun jute involves traditional methods that consume less energy and produce minimal carbon emissions compared to machine-spun jute, making it a more sustainable option. The artisanal process supports local economies and promotes biodiversity by avoiding industrial-scale plantations often linked to deforestation. Machine-spun jute, while efficient for large-scale production, relies heavily on electricity and synthetic machinery, increasing its overall environmental footprint.

Choosing the Right Jute for Your Needs

Handspun jute offers superior texture and strength, making it ideal for artisanal crafts and eco-friendly products that require durability and a natural finish. Machine-spun jute provides uniformity and higher production efficiency, benefiting large-scale manufacturing where consistency and cost-effectiveness are priorities. Selecting the right jute depends on the balance between craftsmanship quality and production volume tailored to specific project requirements.

Handspun Jute vs Machine-spun Jute Infographic

materialdif.com

materialdif.com