Jute and kenaf are both natural fibers prized for their sustainability and versatility, but jute is primarily known for its softness and golden shine, making it ideal for bags and rugs, while kenaf boasts higher tensile strength and quicker growth, suitable for paper and composite products. Jute fibers are extracted from the outer layer of the jute plant's stem, whereas kenaf fibers come from both the outer bark and the inner core, resulting in different fiber textures and applications. Environmental benefits of both fibers include biodegradability and low water usage, positioning them as eco-friendly alternatives in textiles and industrial materials.

Table of Comparison

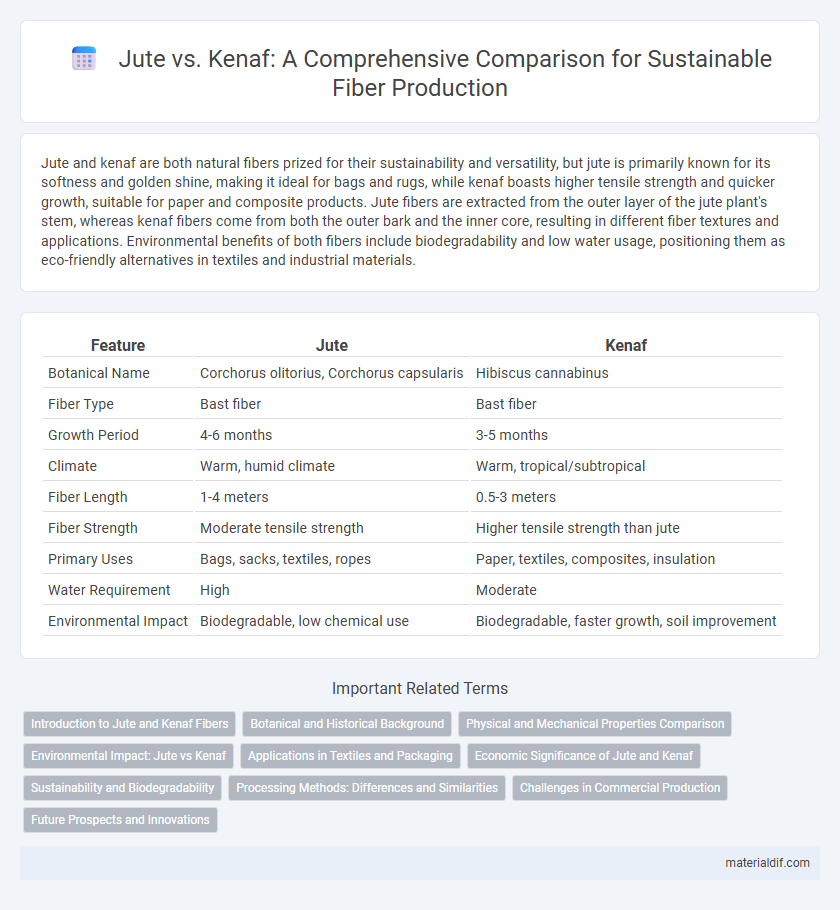

| Feature | Jute | Kenaf |

|---|---|---|

| Botanical Name | Corchorus olitorius, Corchorus capsularis | Hibiscus cannabinus |

| Fiber Type | Bast fiber | Bast fiber |

| Growth Period | 4-6 months | 3-5 months |

| Climate | Warm, humid climate | Warm, tropical/subtropical |

| Fiber Length | 1-4 meters | 0.5-3 meters |

| Fiber Strength | Moderate tensile strength | Higher tensile strength than jute |

| Primary Uses | Bags, sacks, textiles, ropes | Paper, textiles, composites, insulation |

| Water Requirement | High | Moderate |

| Environmental Impact | Biodegradable, low chemical use | Biodegradable, faster growth, soil improvement |

Introduction to Jute and Kenaf Fibers

Jute fibers, derived from the Corchorus plant, are renowned for their softness, strength, and biodegradability, making them a preferred choice for eco-friendly textiles and packaging. Kenaf fibers, obtained from Hibiscus cannabinus, are distinguished by their higher tensile strength and rapid growth, offering versatile applications in paper production and composite materials. Both jute and kenaf contribute significantly to sustainable agriculture by providing renewable raw materials that reduce reliance on synthetic fibers.

Botanical and Historical Background

Jute (Corchorus olitorius and Corchorus capsularis) and Kenaf (Hibiscus cannabinus) both belong to the Malvaceae family, exhibiting fibrous stems ideal for textile production. Jute, cultivated for over 4,000 years primarily in South Asia, holds significant historical importance as a traditional fiber crop, while Kenaf's industrial cultivation began in the 20th century, originating from Africa. Their botanical distinctions lie in leaf shape and fiber texture, with Jute showing thinner, more pliable fibers compared to the coarser and thicker Kenaf fibers used in paper and biocomposites.

Physical and Mechanical Properties Comparison

Jute fibers exhibit higher tensile strength, averaging 400-600 MPa, compared to kenaf, which ranges between 200-400 MPa, making jute more suitable for applications requiring durability. Kenaf demonstrates greater elongation at break, around 2-3%, whereas jute typically shows less than 2%, resulting in kenaf fibers being more flexible under stress. Both fibers have similar cellulose content, approximately 60-70%, but jute's higher lignin content (about 12-14%) enhances its rigidity, contrasting with kenaf's lower lignin level (around 3-5%) that contributes to its softer texture.

Environmental Impact: Jute vs Kenaf

Jute cultivation requires less water and fewer pesticides compared to kenaf, resulting in a lower environmental footprint. Kenaf grows faster and can produce higher yields per acre, but its processing involves more energy-intensive methods, increasing carbon emissions. Overall, jute is considered more eco-friendly due to its sustainable farming practices and biodegradability.

Applications in Textiles and Packaging

Jute fibers, known for their durability and natural luster, are predominantly used in producing high-quality textiles such as hessian, sacking, and carpet backing, offering excellent breathability and biodegradability. Kenaf, with its higher tensile strength and absorbency, finds extensive application in industrial packaging, composite materials, and paper production, outperforming jute in moisture resistance and fiber consistency. Both fibers serve sustainable packaging solutions, but jute remains favored in traditional textile manufacturing while kenaf excels in modern, technical applications requiring enhanced durability.

Economic Significance of Jute and Kenaf

Jute holds substantial economic significance as a major cash crop in South Asia, notably India and Bangladesh, supporting millions of farmers and driving export revenues through its extensive use in packaging, textiles, and eco-friendly products. Kenaf, while gaining recognition for its versatile applications in bioplastics, paper, and construction, currently has a smaller economic footprint but shows promising growth potential in sustainable industries globally. The established jute supply chain and cost-effectiveness maintain its dominance in markets, whereas kenaf's innovation-driven niche markets are expanding due to rising environmental concerns and demand for renewable raw materials.

Sustainability and Biodegradability

Jute and kenaf are both sustainable natural fibers known for their rapid growth and minimal pesticide requirements, making them eco-friendly alternatives to synthetic materials. Jute fibers boast excellent biodegradability, decomposing fully within months in soil, which significantly reduces environmental impact compared to kenaf, whose thicker stalks may take longer to break down. Both crops contribute to carbon sequestration and soil health, but jute's superior biodegradability makes it a preferred choice for environmentally conscious textile and packaging industries.

Processing Methods: Differences and Similarities

Jute and kenaf fibers undergo retting processes to separate fibers from their stalks, but jute primarily uses water retting in stagnant or slow-moving water, while kenaf often utilizes a quicker chemical retting method. Both fibers require fiber softening and stripping during processing, though kenaf processing tends to include additional mechanical decortication to efficiently remove the core. Despite differences, both jute and kenaf share similarities in scutching and combing stages to align and clean fibers for textile and industrial applications.

Challenges in Commercial Production

Jute cultivation faces challenges such as susceptibility to waterlogging and pest infestations, which increase production risks in commercial farming. Kenaf, although more resilient to diverse soil types and having a shorter growth cycle, encounters market acceptance issues and limited processing infrastructure that hinder large-scale commercialization. Both crops require advancements in mechanization and post-harvest processing to enhance economic viability and address supply chain inefficiencies.

Future Prospects and Innovations

Jute and kenaf both exhibit promising future prospects due to their renewable and biodegradable fibers, with jute leading in traditional textile markets and kenaf gaining traction in composite materials and bio-based products. Innovations in genetic modification and sustainable processing techniques are enhancing fiber quality and yield for both crops, positioning them as key players in eco-friendly industries such as packaging, automotive, and construction. Investment in research on blending jute and kenaf fibers offers potential for creating hybrid materials that optimize strength and durability while maintaining environmental benefits.

Jute vs Kenaf Infographic

materialdif.com

materialdif.com