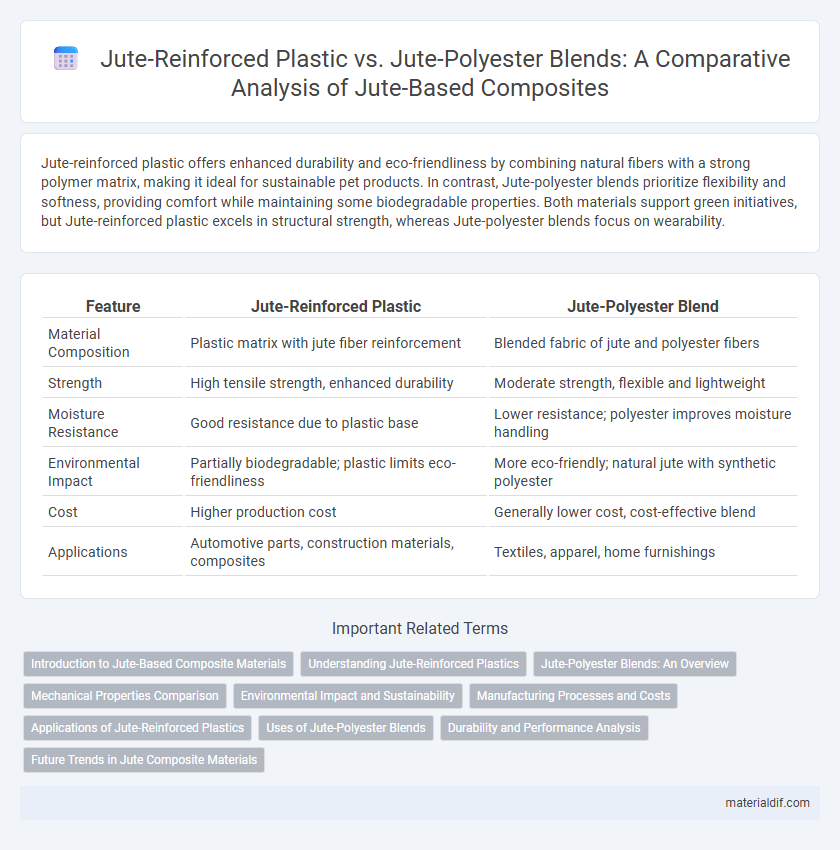

Jute-reinforced plastic offers enhanced durability and eco-friendliness by combining natural fibers with a strong polymer matrix, making it ideal for sustainable pet products. In contrast, Jute-polyester blends prioritize flexibility and softness, providing comfort while maintaining some biodegradable properties. Both materials support green initiatives, but Jute-reinforced plastic excels in structural strength, whereas Jute-polyester blends focus on wearability.

Table of Comparison

| Feature | Jute-Reinforced Plastic | Jute-Polyester Blend |

|---|---|---|

| Material Composition | Plastic matrix with jute fiber reinforcement | Blended fabric of jute and polyester fibers |

| Strength | High tensile strength, enhanced durability | Moderate strength, flexible and lightweight |

| Moisture Resistance | Good resistance due to plastic base | Lower resistance; polyester improves moisture handling |

| Environmental Impact | Partially biodegradable; plastic limits eco-friendliness | More eco-friendly; natural jute with synthetic polyester |

| Cost | Higher production cost | Generally lower cost, cost-effective blend |

| Applications | Automotive parts, construction materials, composites | Textiles, apparel, home furnishings |

Introduction to Jute-Based Composite Materials

Jute-based composite materials harness the natural fibers of jute to enhance the mechanical properties of plastics and polymers, providing eco-friendly alternatives to traditional composites. Jute-reinforced plastic combines jute fibers with thermoset or thermoplastic matrices, resulting in lightweight, biodegradable materials with improved tensile strength and impact resistance. Jute-polyester blends incorporate jute fibers into polyester matrices to optimize flexibility and durability, making them suitable for automotive and construction applications where sustainable material sourcing is prioritized.

Understanding Jute-Reinforced Plastics

Jute-reinforced plastics exhibit enhanced mechanical strength and biodegradability, making them a sustainable alternative to conventional composites in automotive and construction industries. The natural fiber's high tensile strength and low density improve the composite's durability and reduce environmental impact compared to synthetic blends. Techniques like resin impregnation optimize fiber-matrix adhesion, resulting in superior performance for jute-reinforced plastic materials.

Jute-Polyester Blends: An Overview

Jute-polyester blends combine natural jute fibers with synthetic polyester to enhance durability, flexibility, and moisture resistance compared to jute-reinforced plastics. This hybrid material benefits from polyester's tensile strength while maintaining jute's eco-friendly and biodegradable properties, making it ideal for sustainable textile and composite applications. Enhanced thermal stability and improved mechanical performance distinguish jute-polyester blends as versatile alternatives in automotive, packaging, and construction industries.

Mechanical Properties Comparison

Jute-reinforced plastic exhibits superior tensile strength and impact resistance compared to jute-polyester blends, making it more suitable for load-bearing applications. The modulus of elasticity in jute-reinforced plastic is higher, indicating better stiffness and rigidity than the more flexible jute-polyester blend. Jute-polyester blends, while offering improved elongation at break, generally have lower thermal stability and mechanical durability under stress.

Environmental Impact and Sustainability

Jute-reinforced plastics significantly reduce environmental impact by utilizing natural fibers that are biodegradable and require less energy during production compared to conventional synthetic composites. In contrast, jute-polyester blends combine natural fibers with non-biodegradable polyester, resulting in lower overall biodegradability and increased challenges in recycling. The sustainability of jute-reinforced plastics is enhanced through reduced carbon footprint and improved end-of-life degradation, promoting circular economy principles in material design.

Manufacturing Processes and Costs

Jute-reinforced plastic manufacturing involves embedding natural jute fibers within a plastic matrix, typically using compression molding or extrusion, which demands precise fiber treatment to enhance adhesion and water resistance, affecting overall production time and cost. In contrast, jute-polyester blends integrate jute fibers directly into polyester fibers during spinning, resulting in more streamlined manufacturing with lower processing expenses but potentially compromised mechanical strength compared to reinforced plastic composites. The cost efficiency of jute-polyester blends arises from simplified blending and textile processes, while jute-reinforced plastics incur higher expenses due to composite fabrication techniques and quality control requirements.

Applications of Jute-Reinforced Plastics

Jute-reinforced plastics are widely used in automotive panels, furniture, and construction materials due to their high strength-to-weight ratio and biodegradability. These composites offer enhanced mechanical properties and environmental benefits compared to traditional polymer blends, making them suitable for eco-friendly applications. Jute's natural fiber structure improves thermal insulation and impact resistance, which is critical in packaging and building industries.

Uses of Jute-Polyester Blends

Jute-polyester blends are extensively used in the textile and automotive industries due to their enhanced durability and resistance to moisture compared to pure jute-reinforced plastics. These blends offer improved tensile strength making them ideal for upholstery, bag manufacturing, and composite panels in vehicle interiors. The combination of jute's natural biodegradability and polyester's robustness creates sustainable products suitable for eco-friendly fashion and industrial applications.

Durability and Performance Analysis

Jute-reinforced plastic exhibits enhanced durability due to strong fiber-matrix adhesion, providing excellent impact resistance and stiffness compared to traditional composites. In contrast, jute-polyester blends offer improved flexibility and tensile strength, making them suitable for lightweight applications with moderate mechanical demands. Performance analysis reveals that jute-reinforced plastics excel in structural integrity and longevity, while jute-polyester blends prioritize versatility and ease of fabrication.

Future Trends in Jute Composite Materials

Future trends in jute composite materials highlight increasing adoption of jute-reinforced plastics due to their superior mechanical strength, biodegradability, and cost-effectiveness compared to jute-polyester blends. Innovations emphasize enhancing fiber-matrix compatibility and developing eco-friendly resins to improve composite performance in automotive and construction industries. Research also focuses on hybrid composites combining jute with other natural fibers and polymers to achieve tailored properties for sustainable applications.

Jute-reinforced plastic vs Jute-polyester blend Infographic

materialdif.com

materialdif.com