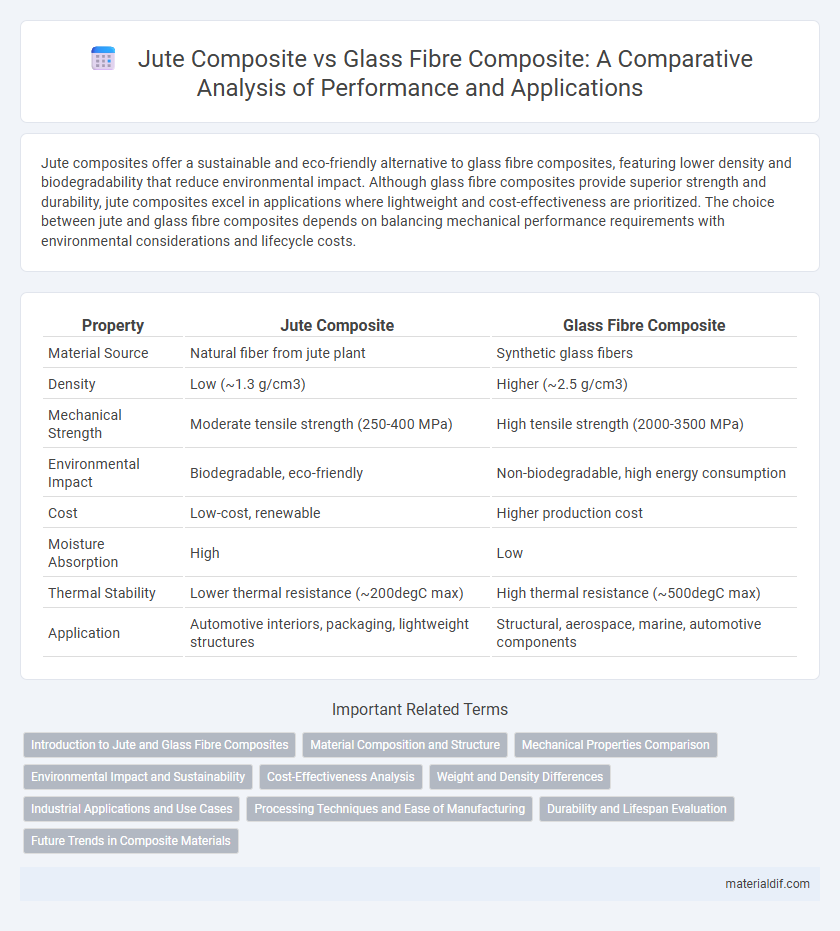

Jute composites offer a sustainable and eco-friendly alternative to glass fibre composites, featuring lower density and biodegradability that reduce environmental impact. Although glass fibre composites provide superior strength and durability, jute composites excel in applications where lightweight and cost-effectiveness are prioritized. The choice between jute and glass fibre composites depends on balancing mechanical performance requirements with environmental considerations and lifecycle costs.

Table of Comparison

| Property | Jute Composite | Glass Fibre Composite |

|---|---|---|

| Material Source | Natural fiber from jute plant | Synthetic glass fibers |

| Density | Low (~1.3 g/cm3) | Higher (~2.5 g/cm3) |

| Mechanical Strength | Moderate tensile strength (250-400 MPa) | High tensile strength (2000-3500 MPa) |

| Environmental Impact | Biodegradable, eco-friendly | Non-biodegradable, high energy consumption |

| Cost | Low-cost, renewable | Higher production cost |

| Moisture Absorption | High | Low |

| Thermal Stability | Lower thermal resistance (~200degC max) | High thermal resistance (~500degC max) |

| Application | Automotive interiors, packaging, lightweight structures | Structural, aerospace, marine, automotive components |

Introduction to Jute and Glass Fibre Composites

Jute composites are natural fiber-reinforced materials known for their sustainability, biodegradability, and low cost, making them an eco-friendly alternative in various applications. Glass fibre composites consist of glass fibers embedded in a polymer matrix, offering superior strength, durability, and resistance to corrosion but at a higher environmental impact. Both materials serve critical roles in automotive, construction, and packaging industries, with jute composites prioritizing environmental benefits and glass fibre composites emphasizing mechanical performance.

Material Composition and Structure

Jute composite consists of natural jute fibers embedded in a biodegradable polymer matrix, offering eco-friendly, lightweight, and renewable material properties. Glass fibre composite incorporates synthetic glass fibers within a thermoset or thermoplastic resin, resulting in higher tensile strength, stiffness, and durability but with less environmental sustainability. The heterogeneous structure of glass fibre composites provides superior mechanical performance, while jute composites emphasize biodegradability and cost-effectiveness in various applications.

Mechanical Properties Comparison

Jute composites exhibit lower tensile strength and modulus compared to glass fibre composites, with typical tensile strength of jute composites ranging from 40 to 80 MPa versus 200 to 350 MPa for glass fibre composites. The elongation at break is generally higher for jute composites, indicating greater flexibility but reduced stiffness relative to the brittle nature of glass fibre composites. Impact strength in jute composites varies based on matrix composition but tends to be lower than glass fibre composites, limiting their use in high-load structural applications.

Environmental Impact and Sustainability

Jute composite materials offer significantly lower environmental impact compared to glass fibre composites due to their biodegradable nature and renewable sourcing from jute plants. The carbon footprint of jute composites is reduced by absorbing CO2 during the growth phase, whereas glass fibre production involves high energy consumption and emits substantial greenhouse gases. Sustainable disposal and recyclability of jute composites further enhance their eco-friendly advantage over traditional glass fibre composites.

Cost-Effectiveness Analysis

Jute composites offer significant cost advantages over glass fibre composites due to lower raw material prices and reduced energy consumption during production. The renewable nature of jute fiber contributes to sustainability while maintaining competitive mechanical properties suitable for non-critical applications. Cost-effectiveness analysis reveals jute composites as an economical alternative, particularly in automotive and construction sectors where environmental impact and budget constraints are key concerns.

Weight and Density Differences

Jute composites exhibit significantly lower weight and density compared to glass fibre composites, making them ideal for lightweight applications. The density of jute composites typically ranges from 1.2 to 1.4 g/cm3, whereas glass fibre composites have densities around 2.0 g/cm3. This substantial difference results in jute composites offering enhanced fuel efficiency and easier handling in automotive and aerospace industries.

Industrial Applications and Use Cases

Jute composites offer advantages in industrial applications requiring lightweight, biodegradable, and cost-effective materials, particularly in automotive interiors, packaging, and construction panels. Glass fibre composites provide superior mechanical strength and durability, making them ideal for demanding use cases such as aerospace components, marine structures, and heavy-duty equipment. The choice between jute and glass fibre composites depends on balancing environmental impact, performance requirements, and production costs.

Processing Techniques and Ease of Manufacturing

Jute composites exhibit simpler processing techniques compared to glass fibre composites, primarily due to the natural fiber's lower density and compatibility with bio-based resins, facilitating easier handling and molding. Manufacturing jute composites often requires lower temperatures and less energy, reducing wear on equipment and enabling eco-friendlier production methods. In contrast, glass fibre composites involve complex processes like high-temperature curing and precise fiber orientation, increasing manufacturing time and cost.

Durability and Lifespan Evaluation

Jute composites exhibit lower durability compared to glass fibre composites due to their natural fiber composition, which is more susceptible to moisture absorption and biological degradation. Glass fibre composites offer superior lifespan, maintaining structural integrity under harsher environmental conditions such as UV exposure and chemical corrosion. The trade-off between eco-friendliness and long-term durability places jute composites as a sustainable but less durable option relative to glass fibre composites in industrial applications.

Future Trends in Composite Materials

Jute composites are gaining traction in sustainable construction due to their biodegradability and lower environmental footprint compared to glass fibre composites, which offer superior strength but rely on non-renewable resources. Emerging research focuses on enhancing jute composite durability and mechanical performance through hybridization and chemical treatments, aiming to close the gap with glass fibre composites. Future trends emphasize eco-friendly material development, lightweight design optimization, and integration of smart technologies for performance monitoring in composite materials.

Jute Composite vs Glass Fibre Composite Infographic

materialdif.com

materialdif.com