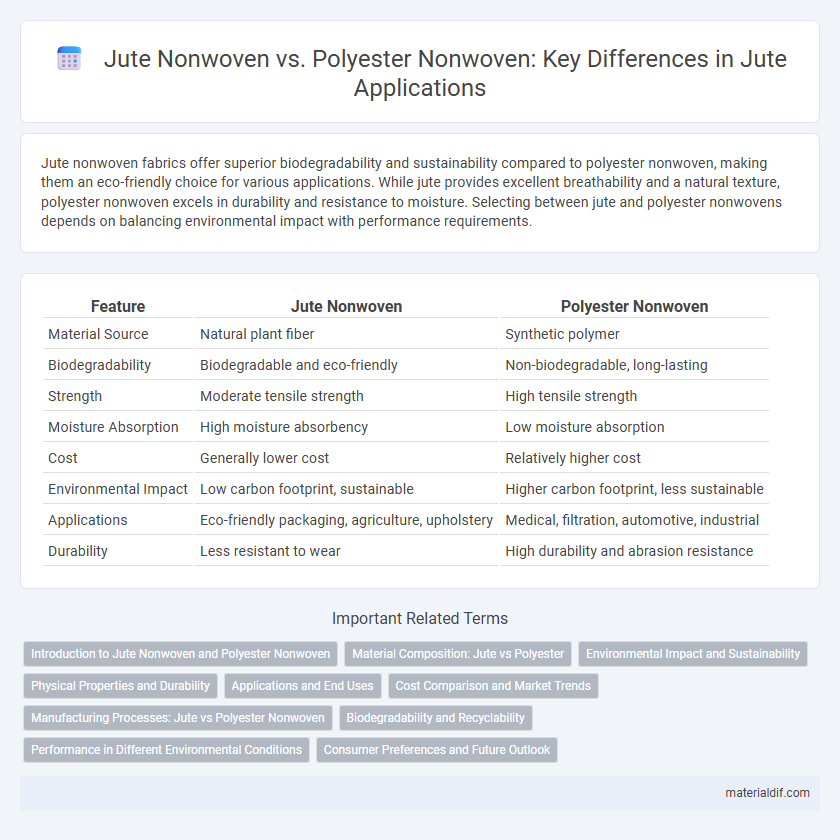

Jute nonwoven fabrics offer superior biodegradability and sustainability compared to polyester nonwoven, making them an eco-friendly choice for various applications. While jute provides excellent breathability and a natural texture, polyester nonwoven excels in durability and resistance to moisture. Selecting between jute and polyester nonwovens depends on balancing environmental impact with performance requirements.

Table of Comparison

| Feature | Jute Nonwoven | Polyester Nonwoven |

|---|---|---|

| Material Source | Natural plant fiber | Synthetic polymer |

| Biodegradability | Biodegradable and eco-friendly | Non-biodegradable, long-lasting |

| Strength | Moderate tensile strength | High tensile strength |

| Moisture Absorption | High moisture absorbency | Low moisture absorption |

| Cost | Generally lower cost | Relatively higher cost |

| Environmental Impact | Low carbon footprint, sustainable | Higher carbon footprint, less sustainable |

| Applications | Eco-friendly packaging, agriculture, upholstery | Medical, filtration, automotive, industrial |

| Durability | Less resistant to wear | High durability and abrasion resistance |

Introduction to Jute Nonwoven and Polyester Nonwoven

Jute nonwoven fabric is derived from natural jute fibers, offering high biodegradability, excellent moisture absorption, and eco-friendly characteristics, making it ideal for sustainable textile applications. Polyester nonwoven fabric, made from synthetic polyester fibers, provides superior durability, water resistance, and dimensional stability, suited for industrial and commercial uses. Comparing both, jute nonwoven serves environmental sustainability goals while polyester nonwoven excels in strength and longevity for varied technical requirements.

Material Composition: Jute vs Polyester

Jute nonwoven fabric is derived from natural plant fibers, making it biodegradable, breathable, and eco-friendly, whereas polyester nonwoven fabric is produced from synthetic polymers like polyethylene terephthalate (PET), offering durability and resistance to moisture. The cellulose-rich structure of jute provides a coarse texture and high tensile strength, while polyester's molecular composition delivers enhanced flexibility and water resistance. Choosing between jute and polyester nonwoven materials depends on the application's need for sustainability versus synthetic performance characteristics.

Environmental Impact and Sustainability

Jute nonwoven fabrics exhibit superior environmental sustainability compared to polyester nonwoven due to their biodegradability and renewable plant-based origin, significantly reducing landfill accumulation and microplastic pollution. The production of jute nonwoven demands lower energy and water resources, enhancing its eco-friendly profile relative to energy-intensive polyester manufacturing reliant on fossil fuels. Jute's carbon sequestration during growth and its ability to decompose naturally make it an optimal choice for sustainable textile applications aiming to minimize ecological footprints.

Physical Properties and Durability

Jute nonwoven fabrics exhibit superior breathability and natural moisture-wicking properties compared to polyester nonwoven, making them more environmentally friendly and biodegradable. While polyester nonwoven offers higher tensile strength, abrasion resistance, and better resilience against UV degradation, jute nonwoven tends to have lower durability under prolonged exposure to moisture and mechanical stress. The natural fiber structure of jute provides excellent insulation and cushioning but compromises longevity compared to the synthetic polyester alternative.

Applications and End Uses

Jute nonwoven fabrics are widely used in eco-friendly packaging, agricultural mats, and geotextiles due to their biodegradable and renewable nature, making them ideal for sustainable applications. Polyester nonwoven materials offer superior durability, moisture resistance, and dimensional stability, finding extensive use in medical textiles, automotive interiors, and filtration products. The choice between jute and polyester nonwovens largely depends on the application requirements, with jute favored for environmentally conscious products and polyester preferred for performance-driven uses.

Cost Comparison and Market Trends

Jute nonwoven fabrics generally offer lower production costs due to the natural abundance and biodegradability of jute fibers, making them a cost-effective alternative to synthetic polyester nonwovens. Market trends indicate increasing demand for sustainable and eco-friendly materials, driving growth in jute nonwoven applications in packaging, agriculture, and automotive sectors. Polyester nonwovens maintain dominance in high-performance applications due to their durability and water resistance, but rising environmental concerns and regulations are accelerating the shift toward jute-based nonwoven solutions.

Manufacturing Processes: Jute vs Polyester Nonwoven

Jute nonwoven fabrics are produced through natural fiber extraction, followed by carding, web formation, and mechanical bonding without chemical treatments, leveraging jute's inherent lignin content for structural integrity. In contrast, polyester nonwoven manufacturing involves polymer melting, fiber extrusion, web formation, and thermal or chemical bonding, enabling mass production with uniform fiber distribution and enhanced durability. The eco-friendly nature of jute processing minimizes environmental impact compared to the energy-intensive and synthetic polymer-based polyester nonwoven production.

Biodegradability and Recyclability

Jute nonwoven fabrics exhibit superior biodegradability compared to polyester nonwoven, decomposing naturally within months due to their organic cellulose fibers. In contrast, polyester nonwoven relies on synthetic polymers that persist in the environment for decades, contributing to microplastic pollution. Jute's recyclable and compostable properties make it an eco-friendly alternative, enhancing sustainable material cycles unlike the limited recyclability of polyester nonwoven.

Performance in Different Environmental Conditions

Jute nonwoven fabrics exhibit superior biodegradability and breathability compared to polyester nonwoven, making them ideal for eco-friendly applications in humid and variable climates. Polyester nonwoven demonstrates higher resistance to UV radiation and moisture, providing enhanced durability in harsh outdoor environments. Performance varies significantly, with jute offering sustainable advantages for temporary use while polyester suits long-term, weather-resistant needs.

Consumer Preferences and Future Outlook

Jute nonwoven fabrics offer superior biodegradability and eco-friendliness compared to polyester nonwoven, appealing strongly to environmentally conscious consumers. Consumer preference is shifting toward sustainable materials, with jute gaining traction in packaging, agriculture, and home textiles due to its natural texture and renewability. Market trends indicate a growing future outlook for jute nonwoven, driven by increasing regulations on plastic use and rising demand for green alternatives in various industries.

Jute Nonwoven vs Polyester Nonwoven Infographic

materialdif.com

materialdif.com