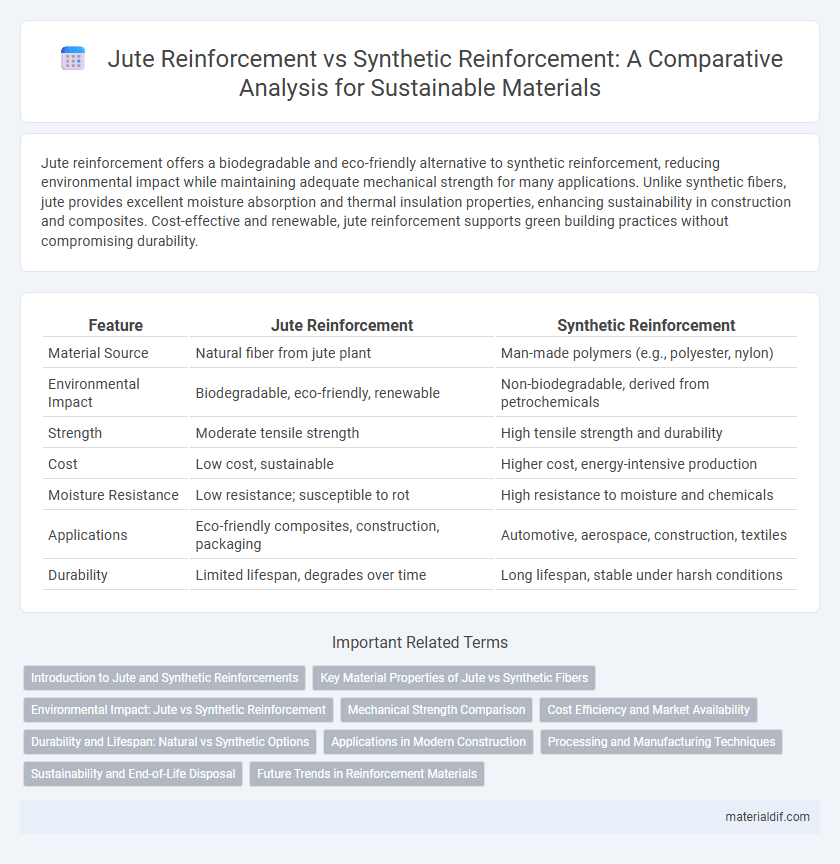

Jute reinforcement offers a biodegradable and eco-friendly alternative to synthetic reinforcement, reducing environmental impact while maintaining adequate mechanical strength for many applications. Unlike synthetic fibers, jute provides excellent moisture absorption and thermal insulation properties, enhancing sustainability in construction and composites. Cost-effective and renewable, jute reinforcement supports green building practices without compromising durability.

Table of Comparison

| Feature | Jute Reinforcement | Synthetic Reinforcement |

|---|---|---|

| Material Source | Natural fiber from jute plant | Man-made polymers (e.g., polyester, nylon) |

| Environmental Impact | Biodegradable, eco-friendly, renewable | Non-biodegradable, derived from petrochemicals |

| Strength | Moderate tensile strength | High tensile strength and durability |

| Cost | Low cost, sustainable | Higher cost, energy-intensive production |

| Moisture Resistance | Low resistance; susceptible to rot | High resistance to moisture and chemicals |

| Applications | Eco-friendly composites, construction, packaging | Automotive, aerospace, construction, textiles |

| Durability | Limited lifespan, degrades over time | Long lifespan, stable under harsh conditions |

Introduction to Jute and Synthetic Reinforcements

Jute reinforcement, derived from natural plant fibers, offers eco-friendly, biodegradable properties with high tensile strength, commonly used in sustainable construction and textile applications. Synthetic reinforcement, typically made from materials like polyester or polypropylene, provides superior durability, resistance to environmental degradation, and consistent mechanical properties suited for heavy-duty industrial uses. Comparing these reinforcements highlights jute's environmental benefits and renewability against the long-lasting performance and structural reliability of synthetic options.

Key Material Properties of Jute vs Synthetic Fibers

Jute fibers exhibit high tensile strength, natural biodegradability, and excellent moisture absorption, making them environmentally sustainable compared to synthetic fibers like glass or carbon, which offer superior tensile modulus and durability but contribute to environmental pollution. Jute's lower density and thermal conductivity provide advantages in lightweight construction and insulation applications, whereas synthetic fibers typically excel in chemical resistance and longevity under harsh conditions. The natural lignin and cellulose composition of jute also enhance its compatibility with biodegradable matrices, while synthetic reinforcements rely on petroleum-based polymers with limited recyclability.

Environmental Impact: Jute vs Synthetic Reinforcement

Jute reinforcement offers significant environmental advantages over synthetic reinforcement due to its biodegradability and renewable nature, reducing long-term waste accumulation. Synthetic reinforcements, primarily derived from petroleum-based polymers, contribute to pollution and carbon emissions during production and disposal. Utilizing jute reinforcement promotes sustainable construction practices by lowering the carbon footprint and minimizing non-biodegradable waste in civil engineering projects.

Mechanical Strength Comparison

Jute reinforcement offers a tensile strength ranging from 200 to 500 MPa, which is lower than synthetic fibers like glass or carbon that typically exceed 1000 MPa. However, jute provides better elongation at break and energy absorption, contributing to improved toughness in composite materials. The mechanical strength of jute composites is suitable for lightweight applications where biodegradability and cost-effectiveness are prioritized over maximum load-bearing capacity.

Cost Efficiency and Market Availability

Jute reinforcement offers a cost-efficient alternative to synthetic fibers, with lower raw material and processing expenses, making it attractive for eco-friendly construction and composites. Market availability of jute is increasing due to its sustainable cultivation primarily in countries like India and Bangladesh, whereas synthetic reinforcement relies on petrochemical sources with fluctuating prices and supply chains. The biodegradability and renewability of jute fibers further enhance their appeal amid growing demand for green materials, despite synthetic reinforcements dominating in strength and durability.

Durability and Lifespan: Natural vs Synthetic Options

Jute reinforcement offers biodegradability and eco-friendliness but generally has a shorter lifespan and lower durability compared to synthetic reinforcement materials like fiberglass and carbon fiber. Synthetic reinforcements exhibit higher resistance to moisture, chemicals, and UV exposure, significantly extending structural longevity in harsh environments. Choosing between jute and synthetic options depends on balancing environmental impact with the required durability and lifespan for specific construction applications.

Applications in Modern Construction

Jute reinforcement in modern construction offers eco-friendly advantages, such as biodegradability and reduced environmental impact, making it ideal for sustainable building projects and green infrastructure. Compared to synthetic reinforcement materials like fiberglass or carbon fiber, jute provides sufficient tensile strength for non-load-bearing structures, insulation panels, and temporary frameworks. Its natural fiber composition enhances thermal insulation and moisture regulation, promoting healthier indoor environments in residential and commercial buildings.

Processing and Manufacturing Techniques

Jute reinforcement involves eco-friendly, low-energy processing techniques such as retting, washing, and mechanical extraction, promoting biodegradability and sustainability in composite manufacturing. Synthetic reinforcement, typically made from polymers like glass or carbon fibers, requires energy-intensive processes including polymerization, extrusion, and high-temperature curing, which increase carbon footprint. Jute composites often utilize simpler, water-based resins and low-temperature curing methods, contrasting with synthetic composites that demand sophisticated chemical treatments and precision control during fabrication.

Sustainability and End-of-Life Disposal

Jute reinforcement offers significant sustainability advantages over synthetic reinforcement due to its natural biodegradability, low carbon footprint, and renewable sourcing from rapidly grown plants. In contrast, synthetic reinforcements, typically made from petroleum-based polymers, pose environmental challenges related to non-biodegradability and microplastic pollution during end-of-life disposal. The eco-friendly lifecycle of jute composites promotes circular economy principles, making jute a preferable choice for sustainable construction and manufacturing applications.

Future Trends in Reinforcement Materials

Jute reinforcement offers a sustainable, biodegradable alternative to synthetic reinforcement materials traditionally used in construction and composites. Future trends indicate a growing emphasis on eco-friendly and renewable resources, with jute's low carbon footprint and excellent mechanical properties driving increased adoption. Advances in hybrid composites combining jute fibers with synthetic materials are also emerging to enhance strength and durability while maintaining environmental benefits.

Jute Reinforcement vs Synthetic Reinforcement Infographic

materialdif.com

materialdif.com