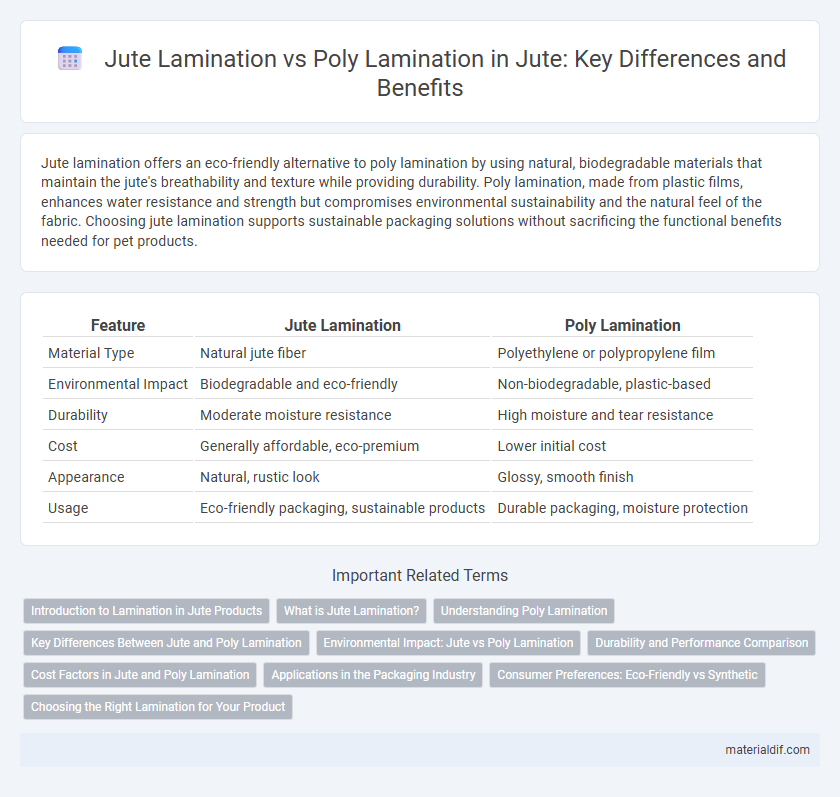

Jute lamination offers an eco-friendly alternative to poly lamination by using natural, biodegradable materials that maintain the jute's breathability and texture while providing durability. Poly lamination, made from plastic films, enhances water resistance and strength but compromises environmental sustainability and the natural feel of the fabric. Choosing jute lamination supports sustainable packaging solutions without sacrificing the functional benefits needed for pet products.

Table of Comparison

| Feature | Jute Lamination | Poly Lamination |

|---|---|---|

| Material Type | Natural jute fiber | Polyethylene or polypropylene film |

| Environmental Impact | Biodegradable and eco-friendly | Non-biodegradable, plastic-based |

| Durability | Moderate moisture resistance | High moisture and tear resistance |

| Cost | Generally affordable, eco-premium | Lower initial cost |

| Appearance | Natural, rustic look | Glossy, smooth finish |

| Usage | Eco-friendly packaging, sustainable products | Durable packaging, moisture protection |

Introduction to Lamination in Jute Products

Lamination in jute products enhances durability and moisture resistance, with jute lamination using natural fibers for eco-friendly reinforcement and poly lamination employing polyethylene for stronger waterproofing. Jute lamination maintains biodegradability, making it ideal for sustainable packaging, while poly lamination offers superior protection against wear and tear in industrial applications. Selecting between jute and poly lamination depends on the balance between environmental impact and functional performance requirements.

What is Jute Lamination?

Jute lamination is a sustainable packaging process that involves bonding a layer of jute fabric onto paper or cardboard to enhance strength and eco-friendliness. Unlike poly lamination, which uses plastic films, jute lamination offers biodegradability and improved breathability, making it ideal for environmentally conscious brands. This natural fiber lamination provides durability while reducing plastic waste and promoting recyclability.

Understanding Poly Lamination

Poly lamination offers superior moisture resistance and durability compared to jute lamination, making it ideal for packaging applications requiring extended shelf life and protection from environmental factors. The synthetic polymer layer in poly lamination provides a smooth, glossy finish that enhances print quality and barrier properties, unlike the natural fiber texture of jute lamination. Choosing poly lamination improves product longevity and consumer appeal, especially in industries like food packaging and retail.

Key Differences Between Jute and Poly Lamination

Jute lamination uses natural fibers that enhance biodegradability and sustainability, while poly lamination relies on synthetic polymers offering superior water resistance and durability. Jute lamination provides a textured, eco-friendly surface ideal for packaging that requires environmental considerations, whereas poly lamination delivers a smoother, glossy finish suited for long-lasting protection against moisture and wear. Cost-effectiveness varies as jute lamination is generally more affordable and compostable, contrasting with the higher expense and non-biodegradability of poly lamination.

Environmental Impact: Jute vs Poly Lamination

Jute lamination offers a biodegradable and compostable alternative to poly lamination, significantly reducing plastic waste and environmental pollution. Poly lamination, derived from petroleum-based plastics, contributes to persistent microplastic contamination and challenges in recycling processes. Choosing jute lamination supports sustainable practices by minimizing carbon footprint and enhancing soil health through natural decomposition.

Durability and Performance Comparison

Jute lamination offers superior breathability and biodegradability compared to poly lamination, making it an eco-friendly choice with moderate durability suitable for lightweight packaging. Poly lamination delivers enhanced water resistance, tensile strength, and overall durability, ideal for heavy-duty applications requiring prolonged protection. Performance-wise, poly lamination excels in moisture barrier properties, while jute lamination provides natural fiber reinforcement that reduces environmental impact.

Cost Factors in Jute and Poly Lamination

Jute lamination generally incurs lower production costs due to the natural, biodegradable fiber's availability and simpler processing requirements compared to poly lamination, which relies on synthetic polymers. Poly lamination involves higher material and energy costs linked to petrochemical-based films, increasing overall expenses despite offering superior moisture resistance and durability. Cost factors in jute lamination emphasize eco-friendly sourcing and lower chemical inputs, while poly lamination prioritizes performance attributes that contribute to its elevated price point.

Applications in the Packaging Industry

Jute lamination offers eco-friendly, biodegradable packaging solutions ideal for agricultural products and organic goods, enhancing sustainability in the packaging industry. Poly lamination provides superior moisture resistance and durability, making it suitable for food packaging and industrial products requiring extended shelf life. Both laminations cater to different market needs, with jute promoting environmental benefits and poly ensuring functional protection.

Consumer Preferences: Eco-Friendly vs Synthetic

Consumers increasingly favor jute lamination over poly lamination due to its eco-friendly properties, biodegradability, and sustainable sourcing. Jute lamination appeals to environmentally conscious buyers seeking natural, renewable materials, while poly lamination involves synthetic polymers that contribute to plastic waste and environmental pollution. Market trends reveal a growing demand for jute-based packaging and products, reflecting a shift toward green alternatives in consumer preferences.

Choosing the Right Lamination for Your Product

Jute lamination offers eco-friendly, biodegradable properties ideal for sustainable packaging, whereas poly lamination provides superior durability and moisture resistance suited for long-lasting protection. Choosing the right lamination depends on the product's exposure to environmental factors and desired shelf life, with jute preferred for organic or natural products and poly favored for items requiring robust barrier protection. Evaluating the balance between environmental impact and functional requirements ensures optimal lamination selection for enhanced product performance.

Jute Lamination vs Poly Lamination Infographic

materialdif.com

materialdif.com