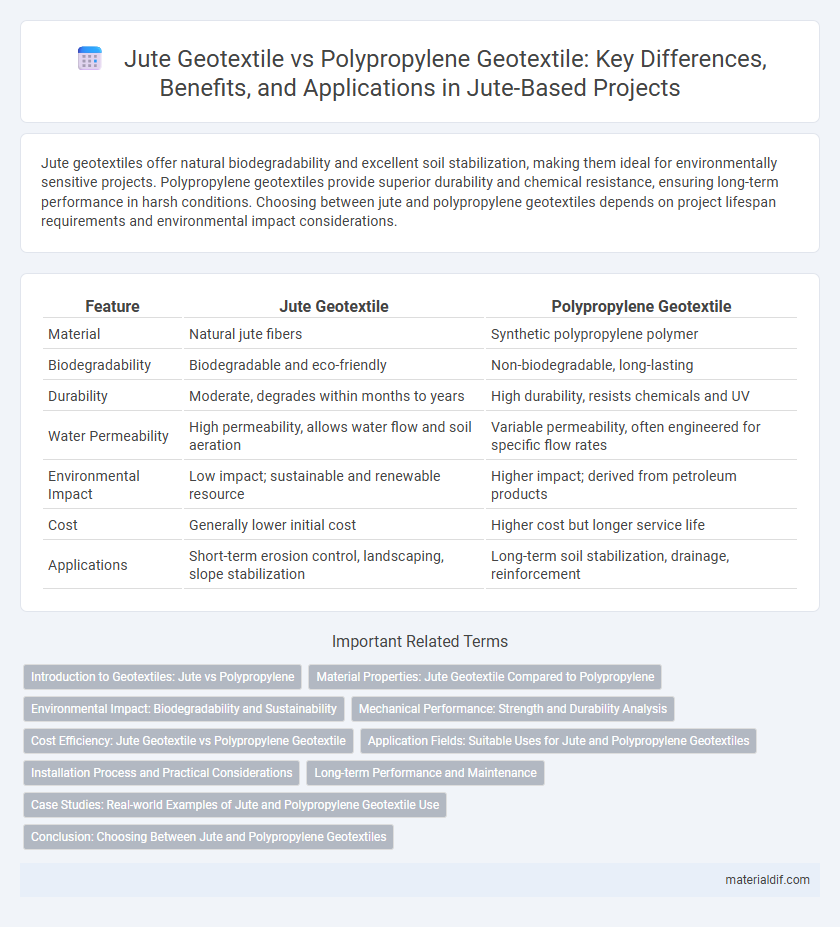

Jute geotextiles offer natural biodegradability and excellent soil stabilization, making them ideal for environmentally sensitive projects. Polypropylene geotextiles provide superior durability and chemical resistance, ensuring long-term performance in harsh conditions. Choosing between jute and polypropylene geotextiles depends on project lifespan requirements and environmental impact considerations.

Table of Comparison

| Feature | Jute Geotextile | Polypropylene Geotextile |

|---|---|---|

| Material | Natural jute fibers | Synthetic polypropylene polymer |

| Biodegradability | Biodegradable and eco-friendly | Non-biodegradable, long-lasting |

| Durability | Moderate, degrades within months to years | High durability, resists chemicals and UV |

| Water Permeability | High permeability, allows water flow and soil aeration | Variable permeability, often engineered for specific flow rates |

| Environmental Impact | Low impact; sustainable and renewable resource | Higher impact; derived from petroleum products |

| Cost | Generally lower initial cost | Higher cost but longer service life |

| Applications | Short-term erosion control, landscaping, slope stabilization | Long-term soil stabilization, drainage, reinforcement |

Introduction to Geotextiles: Jute vs Polypropylene

Jute geotextiles offer natural biodegradability and excellent soil reinforcement, making them ideal for environmentally sustainable erosion control and landscaping projects. Polypropylene geotextiles provide superior tensile strength, chemical resistance, and durability, suitable for heavy-duty applications such as road construction and drainage systems. Both materials serve critical roles in geotechnical engineering, with jute emphasizing eco-friendly biodegradability and polypropylene prioritizing long-term performance.

Material Properties: Jute Geotextile Compared to Polypropylene

Jute geotextile offers natural biodegradability, high tensile strength, and excellent water retention, making it ideal for eco-friendly erosion control and soil stabilization. Polypropylene geotextile exhibits superior chemical resistance, durability, and UV stability, providing long-term performance in harsh environmental conditions. The choice between jute and polypropylene geotextiles depends on project requirements for sustainability versus longevity and resistance to environmental factors.

Environmental Impact: Biodegradability and Sustainability

Jute geotextiles offer significant environmental benefits due to their natural biodegradability, decomposing efficiently without leaving harmful residues, unlike polypropylene geotextiles which persist in landfills for decades. The renewable nature of jute fibers supports sustainable practices by reducing reliance on fossil fuels and minimizing microplastic pollution in soil and waterways. Choosing jute geotextiles aligns with eco-friendly construction and erosion control projects aiming to lower carbon footprints and promote circular economy principles.

Mechanical Performance: Strength and Durability Analysis

Jute geotextiles exhibit moderate tensile strength and biodegradability, making them suitable for temporary erosion control applications, while polypropylene geotextiles offer superior tensile strength and higher durability for long-term soil reinforcement and drainage projects. Polypropylene geotextiles resist chemical and microbial degradation, ensuring extended service life under varying environmental conditions, whereas jute degrades naturally, reducing environmental impact but limiting longevity. Mechanical performance analysis shows polypropylene's strength-to-weight ratio surpasses jute, providing enhanced load-bearing capacity and durability in infrastructure stabilization.

Cost Efficiency: Jute Geotextile vs Polypropylene Geotextile

Jute geotextiles generally offer superior cost efficiency compared to polypropylene geotextiles due to their biodegradability, lower raw material costs, and reduced environmental disposal expenses. Polypropylene geotextiles, while durable and resistant to chemicals, often involve higher initial investment and end-of-life management costs. The choice between jute and polypropylene geotextiles hinges on balancing budget constraints with project lifespan and environmental impact.

Application Fields: Suitable Uses for Jute and Polypropylene Geotextiles

Jute geotextiles excel in erosion control, slope stabilization, and landscaping due to their biodegradability and natural fiber composition, making them ideal for temporary soil reinforcement and vegetation promotion. Polypropylene geotextiles are preferred in road construction, drainage systems, and long-term soil stabilization because of their high tensile strength, chemical resistance, and durability under harsh environmental conditions. Both materials serve critical roles in civil engineering projects, with jute favored for eco-friendly applications and polypropylene for structural integrity and longevity.

Installation Process and Practical Considerations

Jute geotextiles offer easier installation due to their lightweight and natural flexibility, allowing for quick unrolling and shaping on uneven terrains, while polypropylene geotextiles require careful handling to avoid tearing because of their synthetic rigidity. Jute's biodegradable nature demands faster installation and covering to prevent premature degradation upon exposure to sunlight and moisture, contrasting with polypropylene's longer-lasting durability and resistance to chemical and UV degradation. Practical considerations also include jute's eco-friendly disposal and soil-enhancing properties, whereas polypropylene requires recycling management and poses environmental concerns if not properly handled.

Long-term Performance and Maintenance

Jute geotextile offers excellent biodegradability and natural erosion control but has limited long-term durability compared to polypropylene geotextile, which provides superior resistance to UV degradation, chemical exposure, and mechanical stress. Polypropylene geotextiles require less frequent maintenance and exhibit sustained filtration and drainage functions over decades, making them ideal for permanent infrastructure projects. The natural fibers of jute necessitate replacement or reinforcement within a few years, increasing lifecycle maintenance costs relative to polypropylene.

Case Studies: Real-world Examples of Jute and Polypropylene Geotextile Use

Case studies highlight jute geotextile's superior biodegradability and soil stabilization in riverbank erosion projects, offering environmentally sustainable solutions. Polypropylene geotextiles demonstrate long-term durability and resistance to chemical degradation, widely applied in highway subgrade reinforcement and landfill lining. Field performance comparisons reveal jute's advantage in temporary applications and organic soil integration, while polypropylene excels in heavy-load infrastructure and prolonged exposure scenarios.

Conclusion: Choosing Between Jute and Polypropylene Geotextiles

Choosing between jute and polypropylene geotextiles depends on environmental impact, durability, and project requirements. Jute geotextiles offer biodegradability and eco-friendliness, ideal for temporary erosion control and soil stabilization. Polypropylene geotextiles provide superior strength, longevity, and resistance to chemicals, making them suitable for long-term infrastructure projects where durability is critical.

Jute Geotextile vs Polypropylene Geotextile Infographic

materialdif.com

materialdif.com