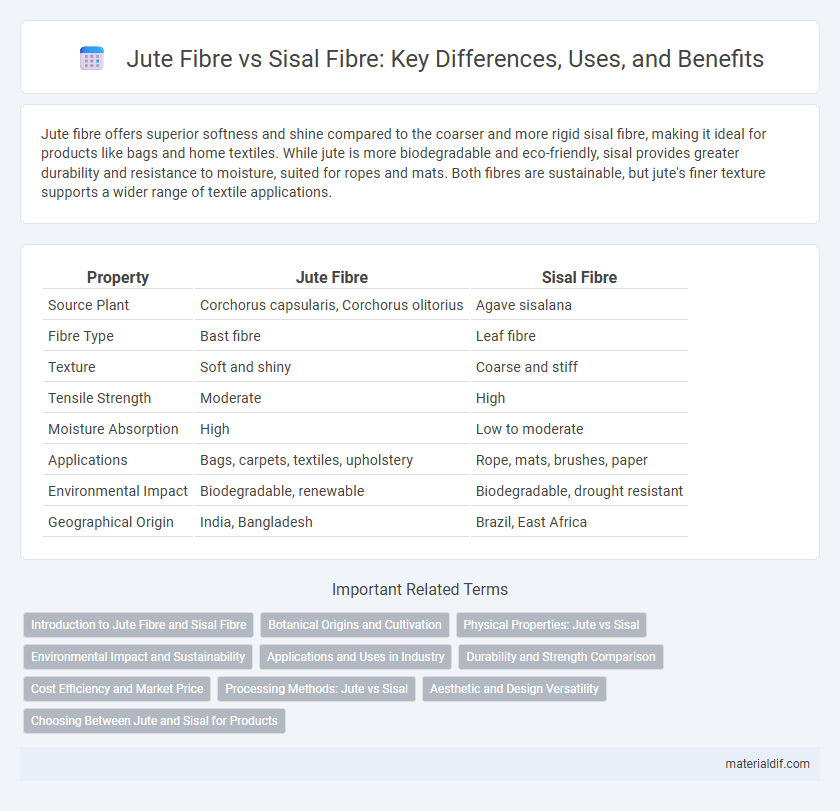

Jute fibre offers superior softness and shine compared to the coarser and more rigid sisal fibre, making it ideal for products like bags and home textiles. While jute is more biodegradable and eco-friendly, sisal provides greater durability and resistance to moisture, suited for ropes and mats. Both fibres are sustainable, but jute's finer texture supports a wider range of textile applications.

Table of Comparison

| Property | Jute Fibre | Sisal Fibre |

|---|---|---|

| Source Plant | Corchorus capsularis, Corchorus olitorius | Agave sisalana |

| Fibre Type | Bast fibre | Leaf fibre |

| Texture | Soft and shiny | Coarse and stiff |

| Tensile Strength | Moderate | High |

| Moisture Absorption | High | Low to moderate |

| Applications | Bags, carpets, textiles, upholstery | Rope, mats, brushes, paper |

| Environmental Impact | Biodegradable, renewable | Biodegradable, drought resistant |

| Geographical Origin | India, Bangladesh | Brazil, East Africa |

Introduction to Jute Fibre and Sisal Fibre

Jute fibre, derived from the Corchorus plant, is a natural, biodegradable material known for its softness, durability, and eco-friendly properties, making it ideal for textiles and packaging. Sisal fibre, extracted from the leaves of the Agave sisalana plant, is stiffer and coarser, commonly used in ropes, mats, and brushes due to its high tensile strength and resistance to moisture. Both fibres are renewable and sustainable, with jute excelling in flexibility and sisal in toughness, catering to diverse industrial applications.

Botanical Origins and Cultivation

Jute fibre originates from the Corchorus genus, primarily Corchorus olitorius and Corchorus capsularis, cultivated mainly in India and Bangladesh due to their warm, humid climates and alluvial soil. Sisal fibre is derived from Agave sisalana, a succulent plant native to Mexico but widely grown in tropical and subtropical regions like Brazil, Tanzania, and Kenya, thriving in arid climates with well-drained soils. The botanical distinction between jute's leafy plants and sisal's spiny agave leaves dictates their differing cultivation requirements and fibre harvesting methods.

Physical Properties: Jute vs Sisal

Jute fibre is softer and more pliable with a tensile strength of around 400-600 MPa, making it suitable for textiles and lightweight packaging. Sisal fibre exhibits greater coarseness and higher tensile strength, typically 700-800 MPa, providing superior durability for ropes and mats. Jute's lower moisture regain of about 13-15% contrasts with sisal's 10-12%, affecting dye absorption and product longevity.

Environmental Impact and Sustainability

Jute fibre, derived from Corchorus plants, offers superior environmental benefits compared to sisal fibre from Agave species due to its lower water consumption and biodegradability, making it a highly sustainable choice for eco-friendly textiles. Jute cultivation enhances soil fertility by adding organic matter and requires minimal pesticides, whereas sisal production often involves intensive water use and chemical inputs. The biodegradable nature of jute reduces landfill waste and carbon footprint, reinforcing its status as a preferred sustainable fibre in green manufacturing.

Applications and Uses in Industry

Jute fibre, known for its fine texture and flexibility, is widely used in making hessian cloth, bags, and upholstery in the textile industry, whereas sisal fibre, characterized by its durability and coarse texture, predominantly serves in rope, mats, and brush manufacturing. Industrial applications leverage jute's biodegradability and moisture retention for eco-friendly packaging and geotextiles, while sisal's strength and resistance to saltwater make it ideal for marine and automotive components. The choice between jute and sisal fibres depends on the specific mechanical properties required, with jute favored for light-duty, flexible products and sisal for heavy-duty, abrasion-resistant uses.

Durability and Strength Comparison

Jute fibre is known for its moderate strength and durability, making it suitable for packaging, sacks, and rugs, while sisal fibre exhibits higher tensile strength and greater resistance to wear, ideal for heavy-duty applications such as ropes and mats. Sisal's natural stiffness contributes to its longer lifespan in outdoor and abrasive environments compared to jute, which degrades faster when exposed to moisture. The molecular structure of sisal includes more lignin, enhancing its durability and toughness relative to the softer and more pliable jute fibre.

Cost Efficiency and Market Price

Jute fibre offers greater cost efficiency compared to sisal fibre due to its lower production expenses and higher yield per hectare, making it a preferred choice for budget-conscious manufacturers. Market prices for jute remain more stable and affordable, typically ranging between $600 and $900 per metric ton, whereas sisal fibre prices fluctuate more widely, often exceeding $1,200 per metric ton. This price advantage, combined with easier cultivation and processing, positions jute fibre as the more economical material in global textile and packaging markets.

Processing Methods: Jute vs Sisal

Jute fiber is extracted through retting, where stalks are soaked in water to loosen the fibers, followed by stripping and drying processes. Sisal fiber involves decortication, where leaves undergo mechanical scraping to separate fibers, then undergo washing and drying for further use. The processing of jute is more water-dependent, whereas sisal processing relies heavily on mechanical equipment to extract robust fibers.

Aesthetic and Design Versatility

Jute fibre offers a natural, lustrous texture that enhances rustic and organic design aesthetics, making it ideal for eco-friendly home decor and textile applications. Sisal fibre, with its coarse and rigid texture, provides a more robust and structured look suited for durable mats and rugs emphasizing texture over refinement. Jute's flexibility allows for intricate weaving and dye absorption, enabling diverse color palettes and pattern possibilities compared to sisal's limited design versatility.

Choosing Between Jute and Sisal for Products

Jute fibre offers a softer texture and higher moisture absorbency, making it ideal for products like bags, carpets, and upholstery where flexibility and comfort are essential. Sisal fibre stands out for its superior strength, durability, and resistance to wear, commonly used in making ropes, mats, and brushes that require toughness and longevity. Selecting between jute and sisal depends on product requirements: jute suits applications needing pliability and aesthetic appeal, while sisal is preferred for heavy-duty, abrasion-resistant items.

Jute Fibre vs Sisal Fibre Infographic

materialdif.com

materialdif.com