Jute and flax are natural fibers valued for their sustainability and versatility, but jute is coarser and primarily used in sacks, carpets, and upholstery, while flax, known for its finer texture, is the source of linen fabric used in clothing and home textiles. Jute thrives in tropical climates with high humidity, making it more suitable for regions like Bangladesh and India, whereas flax grows best in temperate zones, particularly in Europe and North America. Both fibers are biodegradable and environmentally friendly, but flax offers a softer, more durable fabric, whereas jute provides a more affordable and stronger option for heavy-duty applications.

Table of Comparison

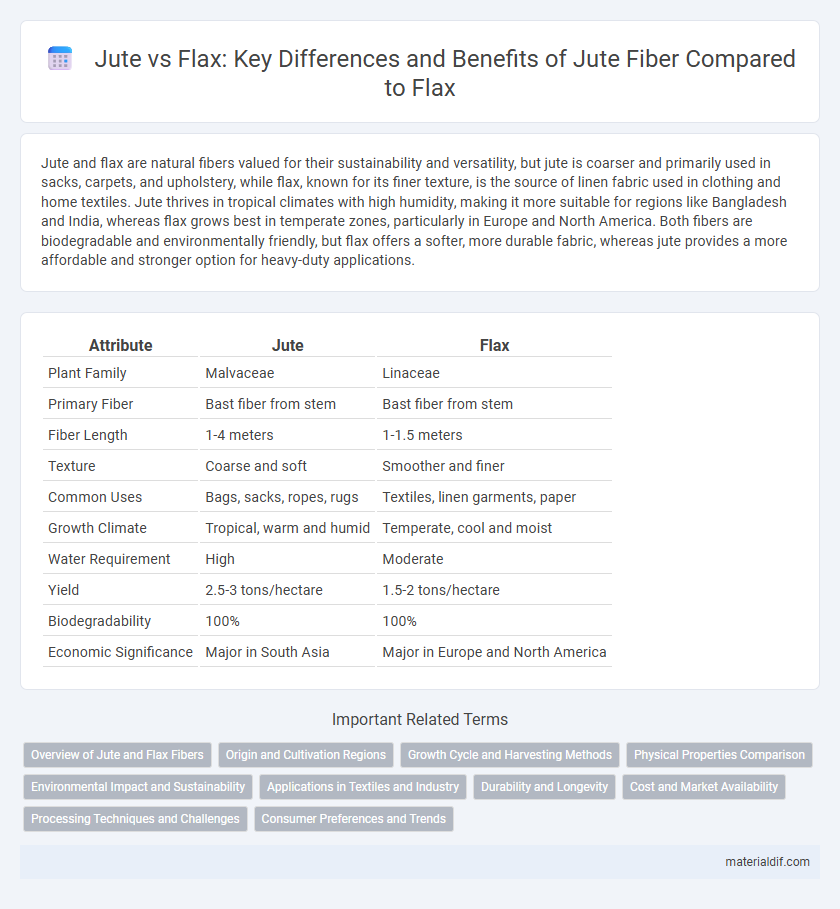

| Attribute | Jute | Flax |

|---|---|---|

| Plant Family | Malvaceae | Linaceae |

| Primary Fiber | Bast fiber from stem | Bast fiber from stem |

| Fiber Length | 1-4 meters | 1-1.5 meters |

| Texture | Coarse and soft | Smoother and finer |

| Common Uses | Bags, sacks, ropes, rugs | Textiles, linen garments, paper |

| Growth Climate | Tropical, warm and humid | Temperate, cool and moist |

| Water Requirement | High | Moderate |

| Yield | 2.5-3 tons/hectare | 1.5-2 tons/hectare |

| Biodegradability | 100% | 100% |

| Economic Significance | Major in South Asia | Major in Europe and North America |

Overview of Jute and Flax Fibers

Jute fibers, derived from the Corchorus plant, are coarse, strong, and primarily used in making sacks, ropes, and mats due to their durability and affordability, while flax fibers come from the Linum usitatissimum plant and are finer, softer, and valued for linen textiles and high-quality fabric production. Jute has high lignin content, making it more rigid and less elastic compared to flax, which has lower lignin and higher cellulose content resulting in greater flexibility and moisture resistance. Both fibers are biodegradable and renewable, with jute typically cultivated in humid tropical regions like India and Bangladesh, whereas flax thrives in cooler, temperate climates such as parts of Europe and Canada.

Origin and Cultivation Regions

Jute primarily originates from the Indian subcontinent, especially in Bangladesh and India, where the Ganges Delta provides an ideal climate with warm temperatures and high humidity for its cultivation. In contrast, flax is predominantly grown in cooler regions such as Canada, Russia, and parts of Europe, thriving in temperate climates with well-drained soils. Jute cultivation favors lowland, waterlogged areas, while flax prefers drier, more temperate environments suitable for its fibrous stems.

Growth Cycle and Harvesting Methods

Jute has a growth cycle of approximately 4 to 6 months, thriving in warm and humid climates with annual rainfall of 1500-2500 mm, while flax requires cooler temperatures and about 100 to 120 days to mature. Jute plants are harvested by retting, where the stalks are submerged in water for 10-30 days to loosen fibers, whereas flax harvesting involves pulling the plants up to retain fiber length followed by dew retting on the field. The differences in harvesting methods significantly impact fiber quality, with flax producing finer and stronger fibers suited for linen, and jute yielding coarser fibers ideal for sacking and upholstery.

Physical Properties Comparison

Jute fibers are coarse, strong, and have low elasticity, making them ideal for burlap and sacks, while flax fibers are finer, smoother, and exhibit higher tensile strength suitable for linen textiles. The moisture absorption rate of jute is higher than flax, contributing to its susceptibility to mildew but enhancing its dye affinity. Flax has greater fiber length and stiffness, resulting in more durable and lightweight fabrics compared to the rough and heavier texture of jute.

Environmental Impact and Sustainability

Jute cultivation requires less water and fewer pesticides compared to flax, resulting in a lower environmental footprint and reduced chemical runoff. Jute plants also absorb more CO2 per hectare, enhancing soil fertility and supporting carbon sequestration efforts. While flax offers versatility in textile applications, jute's biodegradability and faster growth cycle make it a more sustainable choice for eco-friendly products.

Applications in Textiles and Industry

Jute fibers, known for their coarse texture and durability, are primarily used in the production of sacks, rugs, and upholstery, making them ideal for heavy-duty industrial applications. Flax fibers, derived from the flax plant, have finer, smoother qualities suited for high-quality linen fabrics and specialized textiles such as apparel and home furnishings. Industrially, flax's superior strength-to-weight ratio allows for its use in composite materials and insulation, whereas jute remains the preferred choice for eco-friendly packaging and agricultural products.

Durability and Longevity

Jute fibers exhibit moderate durability, suitable for producing sacks and bags that withstand everyday wear, though they tend to degrade faster in moist environments compared to flax. Flax fibers, derived from the flax plant, possess higher tensile strength and longevity, making them ideal for textiles and ropes requiring extended durability. In terms of resistance to environmental factors, flax outperforms jute by maintaining structural integrity over prolonged periods under varying conditions.

Cost and Market Availability

Jute is significantly more cost-effective than flax due to its lower cultivation expenses and higher yield per acre, making it a preferred choice in budget-conscious textile markets. The market availability of jute is more widespread, especially in South Asia, where it dominates production and export, whereas flax cultivation is primarily concentrated in Europe and North America, limiting its global supply. Jute's affordability combined with its abundant supply ensures a competitive edge over flax in cost-sensitive commercial applications.

Processing Techniques and Challenges

Jute processing involves retting, stripping, and drying, which require ample water and lead to environmental concerns, while flax undergoes dew or water retting, scutching, and hackling to extract fibers with higher fineness. Challenges in jute processing include heavy dependence on natural retting, resulting in inconsistent fiber quality and environmental pollution, whereas flax processing demands precise moisture control and mechanical separation to produce strong, smooth fibers. Differences in fiber structure and chemical composition influence the specific machinery and skill sets needed, making flax processing more labor-intensive but yielding finer, more versatile fibers compared to jute.

Consumer Preferences and Trends

Jute, known for its affordability and biodegradable properties, is preferred in markets emphasizing eco-friendly packaging and textiles, while flax appeals more to consumers seeking premium, softer fiber applications like linen clothing. Consumer trends show a rising demand for sustainable materials, leading to increased popularity of jute in home decor and industrial uses due to its coarse texture and durability. Flax remains favored in high-end fashion and artisanal markets where the emphasis is on fiber quality and delicate fabric finishes.

Jute vs Flax Infographic

materialdif.com

materialdif.com