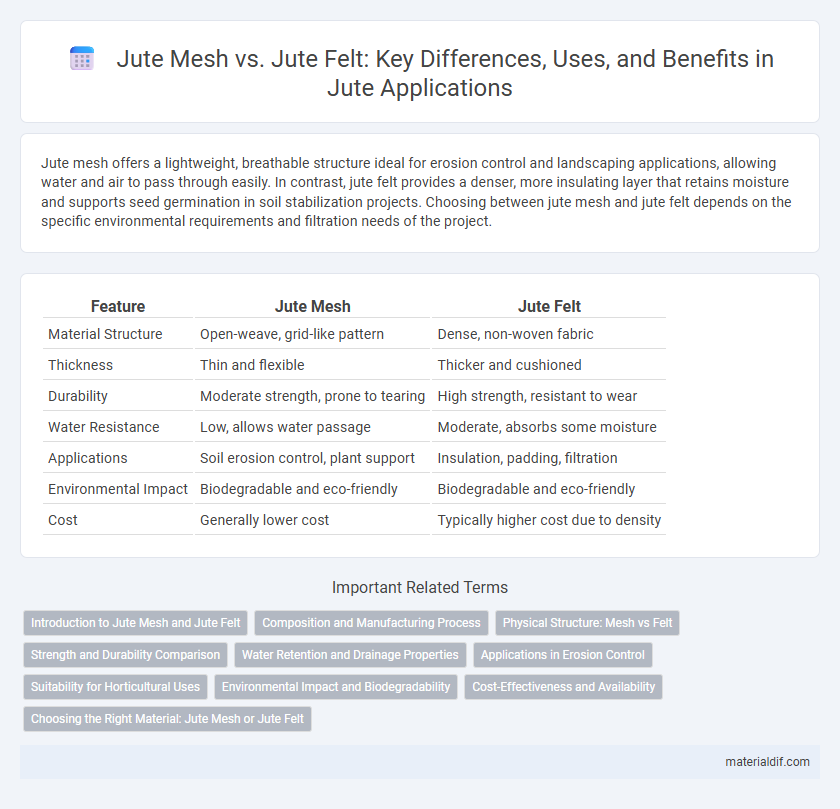

Jute mesh offers a lightweight, breathable structure ideal for erosion control and landscaping applications, allowing water and air to pass through easily. In contrast, jute felt provides a denser, more insulating layer that retains moisture and supports seed germination in soil stabilization projects. Choosing between jute mesh and jute felt depends on the specific environmental requirements and filtration needs of the project.

Table of Comparison

| Feature | Jute Mesh | Jute Felt |

|---|---|---|

| Material Structure | Open-weave, grid-like pattern | Dense, non-woven fabric |

| Thickness | Thin and flexible | Thicker and cushioned |

| Durability | Moderate strength, prone to tearing | High strength, resistant to wear |

| Water Resistance | Low, allows water passage | Moderate, absorbs some moisture |

| Applications | Soil erosion control, plant support | Insulation, padding, filtration |

| Environmental Impact | Biodegradable and eco-friendly | Biodegradable and eco-friendly |

| Cost | Generally lower cost | Typically higher cost due to density |

Introduction to Jute Mesh and Jute Felt

Jute mesh is a woven fabric made from natural jute fibers, characterized by its open, grid-like structure that provides excellent breathability and strength for agricultural and landscaping applications. Jute felt, on the other hand, is a non-woven material produced by matting and pressing jute fibers together, offering superior insulation and cushioning properties ideal for erosion control and padding. Both materials leverage the sustainability and biodegradability of jute, but their distinct textures and manufacturing processes define their specific uses and performance in environmental and industrial contexts.

Composition and Manufacturing Process

Jute mesh consists of woven jute fibers arranged in a grid-like structure, allowing for breathability and flexibility, while jute felt is produced by matting and compressing jute fibers into a dense, non-woven fabric. The manufacturing of jute mesh involves traditional weaving techniques using jute yarns, whereas jute felt is created through a needling or needle-punching process that bonds loose fibers together without weaving. These differences in composition and production result in jute mesh providing mechanical strength and ventilation, whereas jute felt offers insulation and cushioning properties.

Physical Structure: Mesh vs Felt

Jute mesh consists of woven fibers creating a grid-like pattern that offers high breathability and flexibility, making it ideal for erosion control and reinforcement applications. In contrast, jute felt is made from non-woven, densely packed fibers, providing superior insulation, cushioning, and moisture retention. The physical structure of jute mesh enhances drainage and airflow, while jute felt's compact form ensures durability and protection against soil erosion.

Strength and Durability Comparison

Jute mesh exhibits higher tensile strength and better resistance to tearing compared to jute felt, making it ideal for applications requiring structural support. Jute felt, while softer and more flexible, tends to have lower durability under heavy stress or prolonged exposure to environmental elements. The tightly woven structure of jute mesh enhances its longevity and performance in demanding conditions.

Water Retention and Drainage Properties

Jute mesh provides superior drainage due to its open weave structure, facilitating efficient water flow and preventing waterlogging. In contrast, jute felt has a denser texture that enhances water retention, making it ideal for applications requiring moisture preservation. Selecting between jute mesh and jute felt depends on balancing drainage efficiency with the need for sustained moisture in soil management.

Applications in Erosion Control

Jute mesh offers excellent erosion control on steep slopes by reinforcing soil while allowing vegetation to grow through its open weave. Jute felt provides superior moisture retention and soil protection on flat or gently sloping areas, preventing surface erosion by shielding soil from direct rainfall impact. Both materials are biodegradable, making them ideal for environmentally sensitive restoration projects.

Suitability for Horticultural Uses

Jute mesh offers excellent support for climbing plants and soil erosion control due to its open weave structure that allows air and water penetration. Jute felt provides superior moisture retention and weed suppression, making it ideal for mulching and seed germination applications. Both materials are biodegradable and sustainable, but choosing between them depends on the specific horticultural requirement for plant support or soil conservation.

Environmental Impact and Biodegradability

Jute mesh offers enhanced soil erosion control with its open weave design that promotes water permeability and root growth, making it highly effective for environmental conservation. Jute felt, being denser and thicker, provides superior weed suppression and moisture retention but may degrade more slowly due to its compact structure. Both forms of jute are biodegradable, yet the loose weave of jute mesh leads to faster decomposition, minimizing long-term environmental impact compared to the more robust jute felt.

Cost-Effectiveness and Availability

Jute mesh typically offers higher cost-effectiveness due to its lightweight structure and lower material usage, making it ideal for large-scale projects with budget constraints. In contrast, jute felt, being denser and more robust, tends to be more expensive but provides superior durability and insulation benefits. Availability of jute mesh is generally better in regions with established jute industries, while jute felt may require specialized sourcing, affecting procurement timelines.

Choosing the Right Material: Jute Mesh or Jute Felt

Jute mesh offers superior breathability and drainage, making it ideal for applications requiring airflow and moisture control, such as erosion control or horticulture. Jute felt provides enhanced insulation and cushioning due to its dense structure, suitable for upholstery, padding, and craft projects that need durability. Selecting between jute mesh and jute felt depends on the specific functional requirements of the project, balancing breathability against insulation.

Jute mesh vs Jute felt Infographic

materialdif.com

materialdif.com