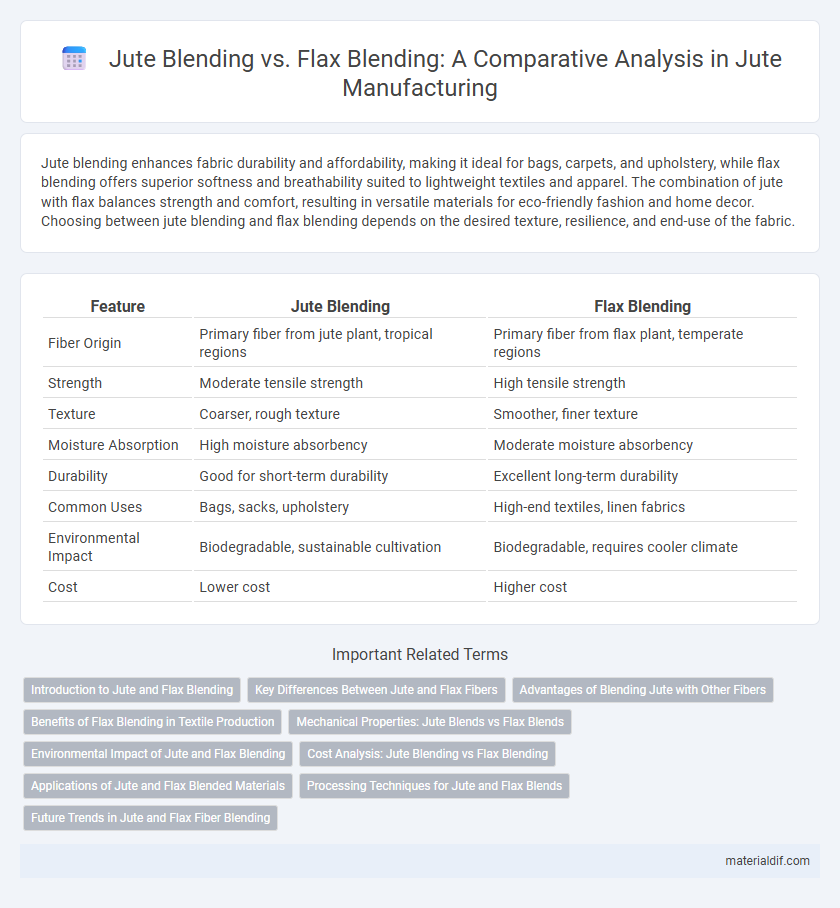

Jute blending enhances fabric durability and affordability, making it ideal for bags, carpets, and upholstery, while flax blending offers superior softness and breathability suited to lightweight textiles and apparel. The combination of jute with flax balances strength and comfort, resulting in versatile materials for eco-friendly fashion and home decor. Choosing between jute blending and flax blending depends on the desired texture, resilience, and end-use of the fabric.

Table of Comparison

| Feature | Jute Blending | Flax Blending |

|---|---|---|

| Fiber Origin | Primary fiber from jute plant, tropical regions | Primary fiber from flax plant, temperate regions |

| Strength | Moderate tensile strength | High tensile strength |

| Texture | Coarser, rough texture | Smoother, finer texture |

| Moisture Absorption | High moisture absorbency | Moderate moisture absorbency |

| Durability | Good for short-term durability | Excellent long-term durability |

| Common Uses | Bags, sacks, upholstery | High-end textiles, linen fabrics |

| Environmental Impact | Biodegradable, sustainable cultivation | Biodegradable, requires cooler climate |

| Cost | Lower cost | Higher cost |

Introduction to Jute and Flax Blending

Jute blending often combines jute fibers with synthetic or natural fibers to enhance strength, durability, and texture, making it suitable for diverse applications such as upholstery and sacks. Flax blending incorporates flax fibers known for their superior softness, luster, and moisture-wicking properties, commonly used in high-quality textiles and linen products. Comparing these blends highlights jute's affordability and coarse texture versus flax's fine, smooth quality, influencing their respective industrial uses and performance characteristics.

Key Differences Between Jute and Flax Fibers

Jute fibers are coarse, longer, and have a higher lignin content, making them less flexible but more affordable and suitable for rough textiles, while flax fibers are finer, stronger, and possess lower lignin, resulting in a softer texture and superior tensile strength. Jute blending produces fabrics that are durable and moisture-resistant, ideal for sacks and upholstery, whereas flax blending yields lighter, lustrous materials commonly used in high-end linens and apparel. The key differences also lie in cultivation requirements and fiber extraction processes, where jute grows faster in warm, humid climates and flax requires cooler, temperate zones.

Advantages of Blending Jute with Other Fibers

Blending jute with other fibers like flax enhances fabric strength and durability, offering greater resistance to wear and tear compared to pure jute materials. This combination improves moisture absorption and breathability, making textiles more comfortable for various applications such as upholstery and apparel. Additionally, blended fabrics benefit from improved texture and versatility, expanding their use in eco-friendly products and sustainable fashion.

Benefits of Flax Blending in Textile Production

Flax blending in textile production enhances fabric strength and durability compared to jute blending, making it ideal for high-quality textiles. The natural luster and softness of flax fibers improve the aesthetic appeal and comfort of blended fabrics. Flax also contributes to better moisture-wicking properties, promoting breathability and reducing mold growth in finished products.

Mechanical Properties: Jute Blends vs Flax Blends

Jute blending enhances tensile strength and abrasion resistance, offering durability suited for packaging and upholstery applications. Flax blending delivers superior stiffness and moisture resistance, improving tensile modulus and dimensional stability ideal for composite materials. Mechanical performance varies with fiber ratio, with jute blends excelling in toughness while flax blends provide enhanced rigidity and resilience.

Environmental Impact of Jute and Flax Blending

Jute blending with flax significantly reduces environmental impact by enhancing biodegradability and decreasing reliance on synthetic fibers, which lowers carbon emissions and waste accumulation. The cultivation of jute requires less water and pesticides compared to flax, making jute-flax composites a more sustainable choice for eco-friendly textiles and packaging materials. Utilizing jute in blends promotes soil health and supports renewable resource cycles, further minimizing ecological footprints in industrial applications.

Cost Analysis: Jute Blending vs Flax Blending

Jute blending offers a cost advantage due to its lower raw material and processing expenses compared to flax blending, which involves higher cultivation and fiber extraction costs. The price per kilogram of jute fibers is substantially less, making jute blends more economical for large-scale textile production. Flax blending may provide superior fiber strength and texture but often results in higher overall manufacturing costs, impacting retail pricing.

Applications of Jute and Flax Blended Materials

Jute blending with flax enhances the durability and biodegradability of fabrics, making them ideal for eco-friendly packaging, upholstery, and home textiles. Flax's natural luster combined with jute's coarse texture creates a versatile material often used in sustainable fashion and industrial sacks. These blended fibers improve moisture resistance and tensile strength, expanding their applications in agriculture and geotextiles.

Processing Techniques for Jute and Flax Blends

Jute blending with flax involves distinct processing techniques that enhance fiber compatibility and product durability, utilizing controlled retting and scutching methods to preserve the natural strength of both fibers. Flax requires delicate processing, such as dew retting and fine hackling, to maintain fiber fineness and flexibility, while jute undergoes water retting and mechanical carding to optimize coarseness and tensile properties. Combining these fibers demands precise blending ratios and specialized machinery to achieve a uniform fiber mix, ensuring improved texture and strength in the final composite material.

Future Trends in Jute and Flax Fiber Blending

Jute blending with synthetic fibers is projected to enhance durability and moisture resistance, positioning it as a sustainable alternative in packaging and textiles. Flax blending emphasizes improved fabric softness and thermal properties, catering to the growing demand in eco-friendly fashion and home textiles. Future trends indicate a convergence of jute and flax blends with bio-based polymers, driving innovation in biodegradable composites and green industrial applications.

Jute Blending vs Flax Blending Infographic

materialdif.com

materialdif.com