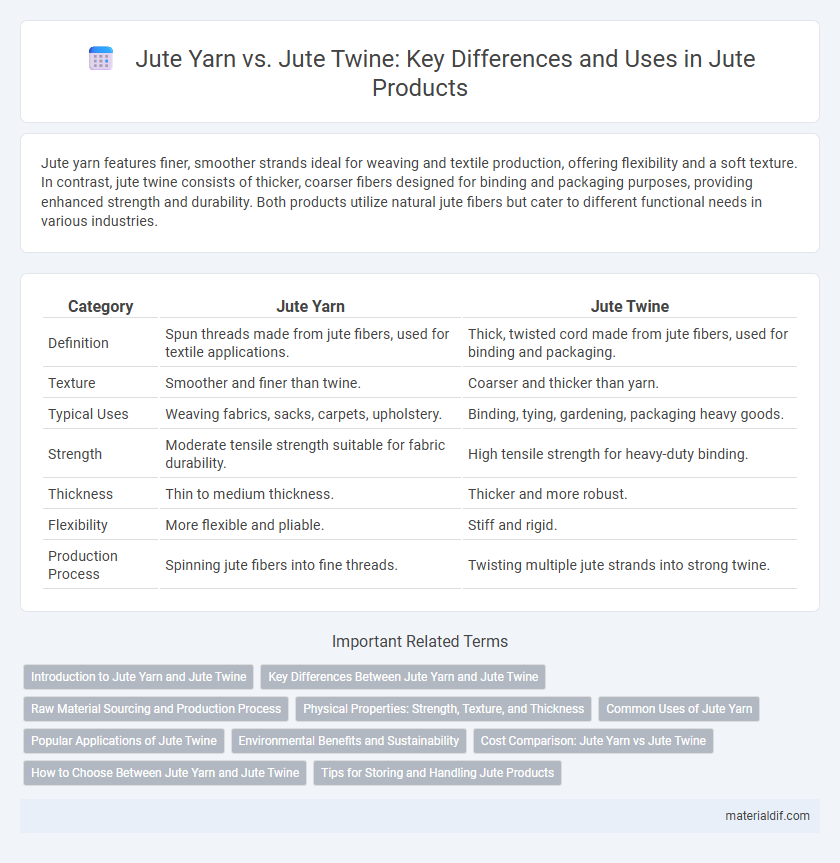

Jute yarn features finer, smoother strands ideal for weaving and textile production, offering flexibility and a soft texture. In contrast, jute twine consists of thicker, coarser fibers designed for binding and packaging purposes, providing enhanced strength and durability. Both products utilize natural jute fibers but cater to different functional needs in various industries.

Table of Comparison

| Category | Jute Yarn | Jute Twine |

|---|---|---|

| Definition | Spun threads made from jute fibers, used for textile applications. | Thick, twisted cord made from jute fibers, used for binding and packaging. |

| Texture | Smoother and finer than twine. | Coarser and thicker than yarn. |

| Typical Uses | Weaving fabrics, sacks, carpets, upholstery. | Binding, tying, gardening, packaging heavy goods. |

| Strength | Moderate tensile strength suitable for fabric durability. | High tensile strength for heavy-duty binding. |

| Thickness | Thin to medium thickness. | Thicker and more robust. |

| Flexibility | More flexible and pliable. | Stiff and rigid. |

| Production Process | Spinning jute fibers into fine threads. | Twisting multiple jute strands into strong twine. |

Introduction to Jute Yarn and Jute Twine

Jute yarn is a natural fiber thread derived from the jute plant, widely used in textiles, ropes, and bags due to its strength and eco-friendliness. Jute twine, on the other hand, is a thicker, twisted cord made from jute fibers, commonly used for packaging, gardening, and craft applications because of its durability and biodegradability. Both jute yarn and jute twine offer sustainable alternatives to synthetic materials, making them popular choices in eco-conscious industries.

Key Differences Between Jute Yarn and Jute Twine

Jute yarn consists of finer, softer threads primarily used in textiles and fabric production, whereas jute twine is thicker, stronger, and designed for binding, packaging, and agricultural applications. Jute yarn typically has a smoother texture suitable for weaving, while jute twine offers greater durability and tensile strength essential for heavy-duty uses. Both derive from the same jute fiber but differ significantly in thickness, strength, and end-use functionality.

Raw Material Sourcing and Production Process

Jute yarn is produced by finely spinning raw jute fibers sourced from the stalks of the Corchorus plant, emphasizing fiber quality and length for smoother texture and enhanced strength in textiles. In contrast, jute twine is made by twisting coarser, shorter jute fibers into sturdy strands, prioritizing durability and tensile strength for packaging and binding applications. The production process for jute yarn involves combing and drawing to align fibers, while jute twine manufacturing focuses on tightening and braiding to achieve robust construction.

Physical Properties: Strength, Texture, and Thickness

Jute yarn exhibits higher tensile strength and a smoother texture compared to jute twine, making it ideal for textile applications requiring durability and fine finish. Jute twine is thicker and coarser, with moderate strength, suitable for tying and packaging purposes where rougher handling is common. Both materials retain natural fiber properties, but yarn's uniform thickness enhances consistency in fabric production.

Common Uses of Jute Yarn

Jute yarn is commonly used in the textile industry for making hessian cloth, sacks, and bags due to its strength and durability, while jute twine is preferred for binding, packaging, and gardening applications. The finer texture of jute yarn makes it ideal for weaving rugs, carpets, and upholstery, providing a natural and eco-friendly alternative to synthetic fibers. Jute yarn's versatility in crafts and industrial use highlights its significance in sustainable manufacturing and packaging solutions.

Popular Applications of Jute Twine

Jute twine is widely used in agriculture for baling hay, securing plants, and supporting crops due to its biodegradable and strong natural fibers. It is also popular in packaging for bundling products, as well as in gardening for tying plants and creating trellises. Unlike jute yarn, which is primarily used in textile manufacturing for making carpets and upholstery, jute twine's coarse texture and durability make it ideal for heavy-duty binding and crafting applications.

Environmental Benefits and Sustainability

Jute yarn and jute twine both offer significant environmental benefits due to their natural biodegradability and renewable sourcing from jute plants. Jute yarn is finer and commonly used in textiles, promoting sustainable fashion by reducing reliance on synthetic fibers, while jute twine is thicker and ideal for eco-friendly packaging and agricultural uses, minimizing plastic waste. Both materials contribute to lowering carbon footprints and support sustainable farming practices, enhancing soil quality without harmful chemicals.

Cost Comparison: Jute Yarn vs Jute Twine

Jute yarn generally costs more than jute twine due to its finer quality and higher manufacturing standards, making it ideal for textile applications. Jute twine is more economical and widely used for packaging, tying, and agricultural purposes because of its thicker, coarser texture. In terms of overall cost-effectiveness, jute twine offers significant savings for industrial uses, while jute yarn justifies its higher price with superior softness and durability for garment production.

How to Choose Between Jute Yarn and Jute Twine

Choosing between jute yarn and jute twine depends on the intended application, with jute yarn being ideal for textile crafts, weaving, and finer fabric production due to its softer, more flexible strands. Jute twine features thicker, stronger fibers designed for tying, binding, and packaging, making it suitable for heavy-duty tasks requiring durability and strength. Assessing the project's strength requirements and texture preferences ensures selecting the appropriate jute product for optimal performance.

Tips for Storing and Handling Jute Products

Jute yarn and jute twine require proper storage in a cool, dry environment to prevent moisture absorption that can lead to mold and weakening of fibers. Handling these jute products with care avoids excessive tension, which may cause fraying or breakage, preserving their durability. Keeping jute materials away from direct sunlight helps maintain their natural strength and color integrity over time.

Jute Yarn vs Jute Twine Infographic

materialdif.com

materialdif.com