Jute mesh offers an eco-friendly alternative to plastic mesh, providing biodegradable and sustainable properties that reduce environmental impact. Unlike plastic mesh, jute mesh allows better air and water permeability, promoting healthier plant growth and soil conditions. Its natural fibers decompose naturally, preventing microplastic pollution commonly associated with plastic mesh.

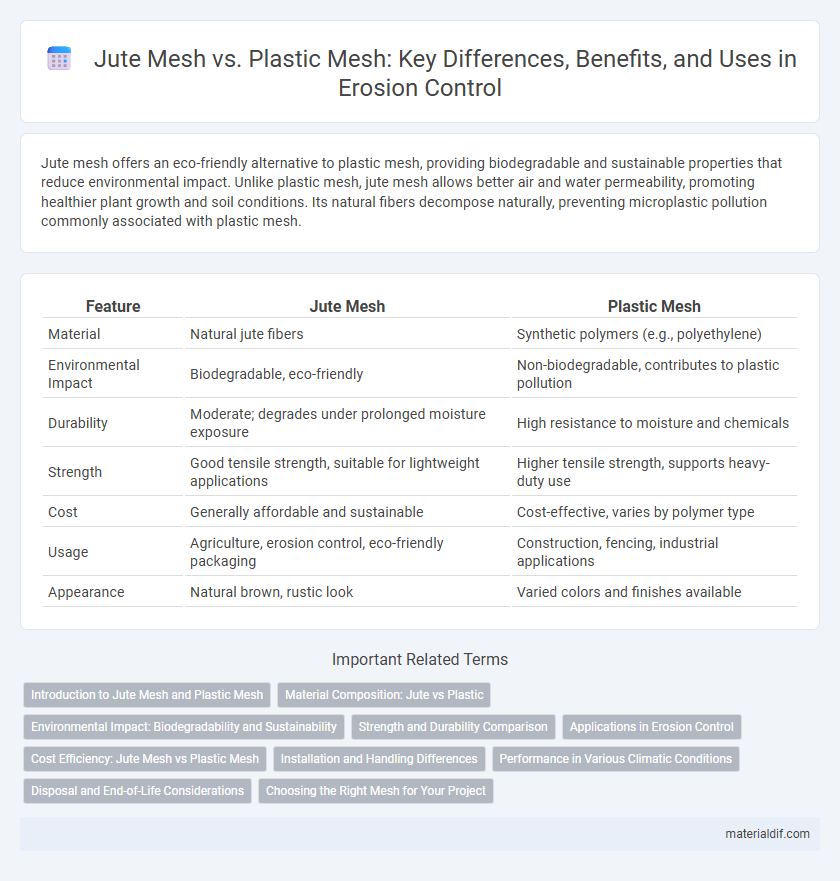

Table of Comparison

| Feature | Jute Mesh | Plastic Mesh |

|---|---|---|

| Material | Natural jute fibers | Synthetic polymers (e.g., polyethylene) |

| Environmental Impact | Biodegradable, eco-friendly | Non-biodegradable, contributes to plastic pollution |

| Durability | Moderate; degrades under prolonged moisture exposure | High resistance to moisture and chemicals |

| Strength | Good tensile strength, suitable for lightweight applications | Higher tensile strength, supports heavy-duty use |

| Cost | Generally affordable and sustainable | Cost-effective, varies by polymer type |

| Usage | Agriculture, erosion control, eco-friendly packaging | Construction, fencing, industrial applications |

| Appearance | Natural brown, rustic look | Varied colors and finishes available |

Introduction to Jute Mesh and Plastic Mesh

Jute mesh, derived from natural jute fibers, offers a biodegradable and eco-friendly alternative to plastic mesh, which is made from synthetic polymers like polypropylene. Jute mesh excels in applications requiring breathability, soil erosion control, and sustainable agriculture due to its natural decomposition properties. Plastic mesh, while durable and resistant to moisture, poses environmental challenges as it does not biodegrade, contributing to long-term plastic waste.

Material Composition: Jute vs Plastic

Jute mesh is composed of natural plant fibers derived from the jute plant, offering biodegradability and eco-friendliness, while plastic mesh is made from synthetic polymers such as polyethylene or polypropylene, which are non-biodegradable and rely on fossil fuels for production. The cellulose-rich structure of jute provides breathability and natural resistance to UV degradation, contrasting with plastic mesh's durability and resistance to moisture but limited environmental compatibility. Material composition differences impact disposal, environmental impact, and application suitability in agriculture, packaging, and construction sectors.

Environmental Impact: Biodegradability and Sustainability

Jute mesh offers superior environmental benefits compared to plastic mesh due to its natural biodegradability and compostability, breaking down within months without releasing harmful microplastics. The cultivation of jute is sustainable, requiring minimal pesticides and water, and it enhances soil health through carbon sequestration. In contrast, plastic mesh persists in ecosystems for decades, contributing to pollution and harming wildlife, while its production relies heavily on fossil fuels.

Strength and Durability Comparison

Jute mesh offers natural strength with moderate durability, ideal for eco-friendly applications but may degrade faster under prolonged moisture exposure. Plastic mesh provides superior tensile strength and exceptional resistance to water, UV rays, and chemicals, ensuring long-term durability in harsh environments. Comparing both, plastic mesh outperforms jute mesh in strength and longevity, while jute remains a sustainable alternative for less demanding uses.

Applications in Erosion Control

Jute mesh offers superior biodegradability and natural soil integration in erosion control applications, making it ideal for temporary stabilization on slopes and riverbanks. Plastic mesh, while durable and resistant to environmental degradation, often causes long-term environmental concerns due to its persistence and potential to disrupt soil ecosystems. Selecting jute mesh supports sustainable erosion management by promoting vegetation growth and soil health, whereas plastic mesh primarily serves in situations requiring extended structural support.

Cost Efficiency: Jute Mesh vs Plastic Mesh

Jute mesh offers superior cost efficiency compared to plastic mesh due to its biodegradable nature and lower production expenses, making it an eco-friendly and budget-conscious choice. Plastic mesh, while durable, incurs higher manufacturing and disposal costs, impacting long-term savings negatively. Opting for jute mesh reduces both environmental impact and total expenditure in agricultural and construction applications.

Installation and Handling Differences

Jute mesh offers superior ease of installation due to its lightweight and flexible natural fibers, which allow quick cutting and shaping without specialized tools. Plastic mesh tends to be stiffer and requires more effort to handle, often needing gloves to prevent discomfort and tools to achieve precise fitting. The biodegradable nature of jute also ensures less environmental impact during disposal, contrasting with the non-biodegradable plastic mesh that adds to landfill waste.

Performance in Various Climatic Conditions

Jute mesh offers superior biodegradability and natural breathability, enhancing its performance in humid and warm climates by reducing mold and mildew buildup. Plastic mesh excels in durability and water resistance, maintaining structural integrity in wet or cold environments but often causing environmental concerns due to non-biodegradability. Both materials perform differently depending on climate, with jute mesh favoring sustainability in temperate zones and plastic mesh providing longevity under harsh weather conditions.

Disposal and End-of-Life Considerations

Jute mesh biodegrades naturally within months, decomposing into non-toxic organic matter that enriches soil, while plastic mesh often persists for decades, contributing to microplastic pollution. The compostability of jute mesh supports sustainable waste management practices and reduces landfill burden, contrasting sharply with the environmental hazards posed by plastic mesh disposal. Choosing jute mesh significantly lowers ecological footprint through its favorable end-of-life decomposition and minimal environmental impact.

Choosing the Right Mesh for Your Project

Jute mesh offers eco-friendly benefits with its natural biodegradability and breathability, making it ideal for agricultural and landscaping projects focused on sustainability. Plastic mesh, known for its durability and resistance to moisture, suits long-term applications requiring strength and weather resistance. Evaluating project needs such as environmental impact, longevity, and material performance guides the choice between jute mesh and plastic mesh.

Jute Mesh vs Plastic Mesh Infographic

materialdif.com

materialdif.com