Soda-lime glass is the most common type of glass, composed primarily of silica, soda, and lime, offering good clarity and affordability but lower thermal resistance. Borosilicate glass contains boron oxide, providing superior thermal shock resistance and durability, making it ideal for laboratory and kitchenware applications. The choice between soda-lime and borosilicate glass depends on the need for heat resistance and chemical durability.

Table of Comparison

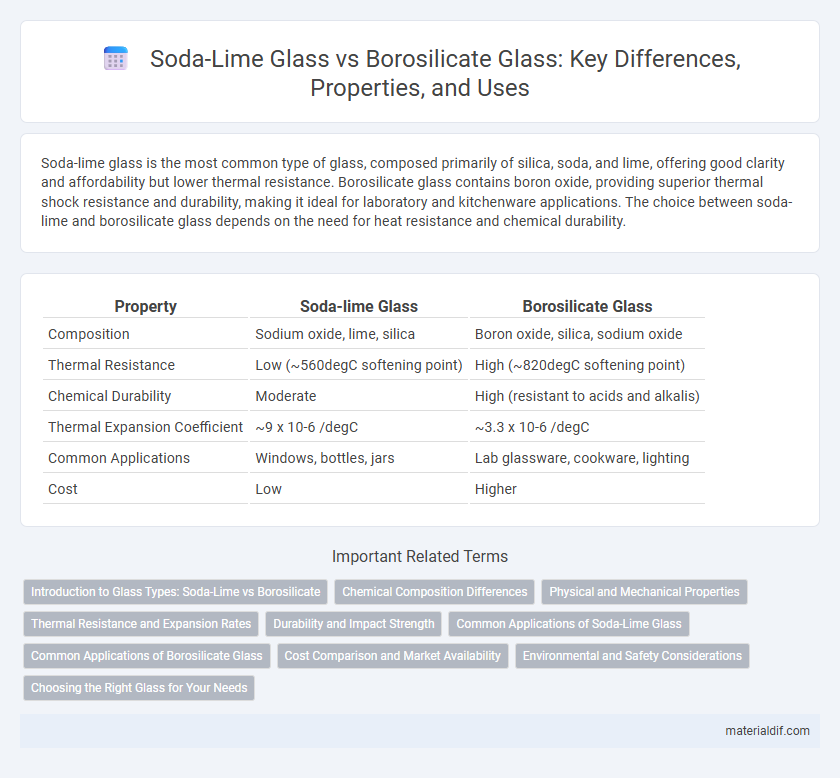

| Property | Soda-lime Glass | Borosilicate Glass |

|---|---|---|

| Composition | Sodium oxide, lime, silica | Boron oxide, silica, sodium oxide |

| Thermal Resistance | Low (~560degC softening point) | High (~820degC softening point) |

| Chemical Durability | Moderate | High (resistant to acids and alkalis) |

| Thermal Expansion Coefficient | ~9 x 10-6 /degC | ~3.3 x 10-6 /degC |

| Common Applications | Windows, bottles, jars | Lab glassware, cookware, lighting |

| Cost | Low | Higher |

Introduction to Glass Types: Soda-Lime vs Borosilicate

Soda-lime glass, composed mainly of silica, soda, and lime, is the most common glass type used for windows, bottles, and jars due to its affordability and good chemical durability. Borosilicate glass, containing silica and boron trioxide, offers enhanced thermal resistance and mechanical strength, making it ideal for laboratory glassware and cookware. The primary distinction lies in borosilicate's ability to withstand rapid temperature changes without cracking, unlike soda-lime glass.

Chemical Composition Differences

Soda-lime glass primarily consists of about 70-75% silica (SiO2), with significant amounts of sodium oxide (Na2O) and calcium oxide (CaO), which lower the melting point and improve workability. Borosilicate glass contains roughly 70-80% silica but replaces a portion of the sodium oxide with boron oxide (B2O3), enhancing thermal resistance and chemical durability. The presence of boron oxide in borosilicate glass reduces thermal expansion, making it more resistant to thermal shock compared to soda-lime glass.

Physical and Mechanical Properties

Soda-lime glass exhibits lower thermal resistance and higher brittleness compared to borosilicate glass, making it more prone to breakage under thermal stress. Borosilicate glass contains boron oxide, which enhances its thermal stability, chemical durability, and mechanical strength, enabling it to withstand rapid temperature changes and mechanical impact. The modulus of elasticity of borosilicate glass is generally higher, providing better resistance to deformation under mechanical loads than soda-lime glass.

Thermal Resistance and Expansion Rates

Soda-lime glass exhibits a higher thermal expansion rate around 9 x 10^-6 /degC, making it more prone to thermal shock and less suitable for high-temperature applications compared to borosilicate glass. Borosilicate glass features a significantly lower thermal expansion rate of approximately 3.3 x 10^-6 /degC, providing superior thermal resistance and enhanced durability under rapid temperature changes. This low expansion coefficient enables borosilicate glass to maintain structural integrity in laboratory equipment and cookware exposed to extreme heat fluctuations.

Durability and Impact Strength

Soda-lime glass exhibits moderate durability and impact strength, making it suitable for everyday applications like windows and bottles but prone to breaking under sudden shocks. Borosilicate glass offers superior durability and significantly higher impact resistance due to its low thermal expansion coefficient, making it ideal for laboratory glassware and high-stress environments. The enhanced toughness of borosilicate glass reduces the risk of fractures caused by thermal or mechanical stress compared to soda-lime glass.

Common Applications of Soda-Lime Glass

Soda-lime glass is widely used in everyday applications such as window panes, glass containers, and bottles due to its low cost and ease of manufacturing. Its chemical composition, primarily sodium carbonate, lime, and silica, provides sufficient durability for common consumer products and architectural glazing. This type of glass is also favored for solar panels and light bulbs because of its excellent transparency and thermal properties.

Common Applications of Borosilicate Glass

Borosilicate glass is widely used in laboratory glassware, such as beakers and test tubes, due to its high thermal resistance and chemical durability. It is also common in cookware and bakeware, including brands like Pyrex, because it can withstand rapid temperature changes without breaking. Furthermore, borosilicate glass is preferred for manufacturing optical lenses, smartphone screens, and chemical storage containers, thanks to its durability and resistance to thermal shock.

Cost Comparison and Market Availability

Soda-lime glass is significantly less expensive than borosilicate glass due to its simpler manufacturing process and widespread use in everyday products like windows and bottles. Borosilicate glass, favored for its thermal resistance and durability in scientific and laboratory applications, commands a higher price and has more limited market availability. The extensive production and distribution infrastructure for soda-lime glass make it readily accessible globally, whereas borosilicate glass is typically sourced from specialized suppliers.

Environmental and Safety Considerations

Soda-lime glass, the most common glass type, has a lower melting temperature, resulting in less energy consumption during production but contains higher amounts of sodium oxide, which can leach into the environment if not properly recycled. Borosilicate glass, known for its thermal and chemical resistance, requires more energy to produce but offers superior durability and safety in applications involving rapid temperature changes, reducing breakage and environmental waste. While both glasses are recyclable, borosilicate glass's longer lifespan and resistance to chemicals make it a safer choice for laboratory and cookware use, minimizing hazardous exposure and environmental impact.

Choosing the Right Glass for Your Needs

Soda-lime glass is ideal for everyday applications due to its affordability and good thermal resistance but is prone to thermal shock. Borosilicate glass offers superior durability, higher resistance to thermal expansion, and chemical stability, making it suitable for laboratory equipment and high-heat environments. Selecting the right glass depends on the application's temperature range, durability requirements, and budget constraints.

Soda-lime glass vs Borosilicate glass Infographic

materialdif.com

materialdif.com