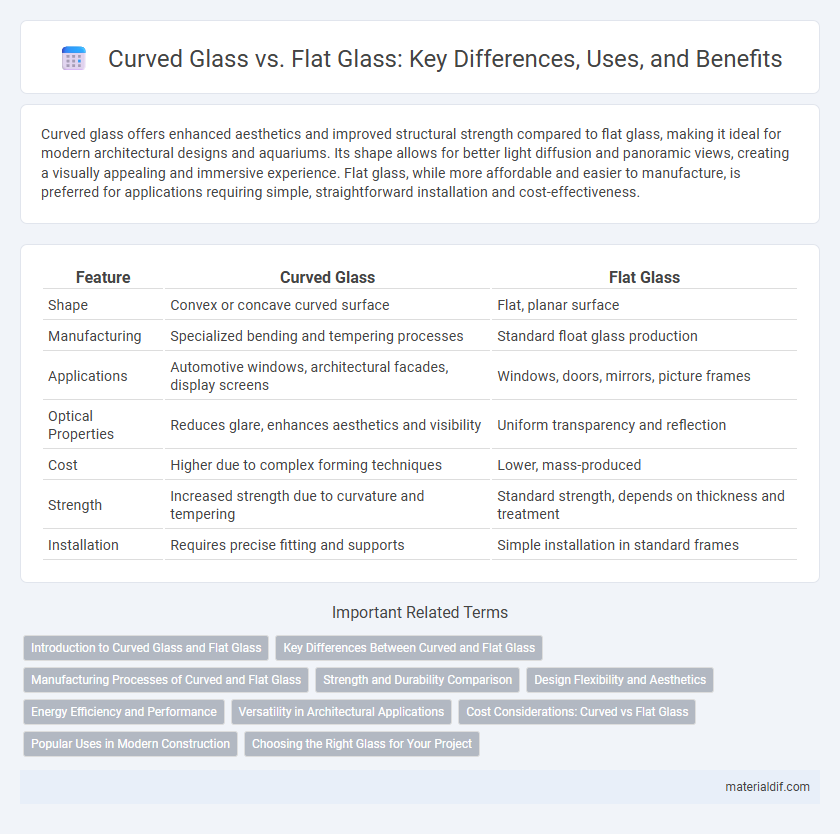

Curved glass offers enhanced aesthetics and improved structural strength compared to flat glass, making it ideal for modern architectural designs and aquariums. Its shape allows for better light diffusion and panoramic views, creating a visually appealing and immersive experience. Flat glass, while more affordable and easier to manufacture, is preferred for applications requiring simple, straightforward installation and cost-effectiveness.

Table of Comparison

| Feature | Curved Glass | Flat Glass |

|---|---|---|

| Shape | Convex or concave curved surface | Flat, planar surface |

| Manufacturing | Specialized bending and tempering processes | Standard float glass production |

| Applications | Automotive windows, architectural facades, display screens | Windows, doors, mirrors, picture frames |

| Optical Properties | Reduces glare, enhances aesthetics and visibility | Uniform transparency and reflection |

| Cost | Higher due to complex forming techniques | Lower, mass-produced |

| Strength | Increased strength due to curvature and tempering | Standard strength, depends on thickness and treatment |

| Installation | Requires precise fitting and supports | Simple installation in standard frames |

Introduction to Curved Glass and Flat Glass

Curved glass features a gently bent surface, engineered through heat or pressure to achieve its shape, enhancing architectural aesthetics with smooth, continuous lines. Flat glass, produced by the float glass process, offers uniform thickness and a smooth, planar surface ideal for windows and facades. Both types serve distinct design and functional purposes, with curved glass enabling dynamic shapes and flat glass providing classic, straightforward applications.

Key Differences Between Curved and Flat Glass

Curved glass offers enhanced structural strength and aesthetic appeal compared to flat glass, making it ideal for architectural applications requiring seamless, flowing designs. Unlike flat glass, which is produced by floating molten glass on a bed of molten metal to create uniform thickness and smooth surfaces, curved glass undergoes specialized heating and bending processes to achieve precise curvature. The performance differences impact factors such as light refraction, thermal insulation, and load distribution, where curved glass typically provides superior resistance to external forces and enhanced visual dynamics in construction and automotive industries.

Manufacturing Processes of Curved and Flat Glass

Curved glass manufacturing involves heating flat glass sheets in a furnace until they reach a pliable state, allowing them to be shaped over molds through gravity or press bending techniques, ensuring precise curvature and structural integrity. In contrast, flat glass production primarily utilizes the float glass process, where molten glass spreads over a bath of molten tin, creating uniform, smooth, and flat panels with consistent thickness. The controlled cooling and tempering processes in both methods optimize durability and optical clarity suited for architectural and automotive applications.

Strength and Durability Comparison

Curved glass demonstrates superior strength and impact resistance compared to flat glass due to its geometry, which distributes stress more evenly across the surface. The inherent structural rigidity of curved shapes enhances durability, making curved glass less prone to breakage under pressure or thermal expansion. Flat glass, while easier to manufacture and install, lacks this stress-dispersing advantage, resulting in lower resistance to mechanical and environmental stresses.

Design Flexibility and Aesthetics

Curved glass offers superior design flexibility by enabling seamless, organic shapes that enhance architectural aesthetics and allow for innovative building facades. Unlike flat glass, curved glass provides a sleek, modern appearance that complements dynamic structures and improves natural light diffusion. This versatility makes curved glass a preferred choice for projects requiring both functional performance and visually striking designs.

Energy Efficiency and Performance

Curved glass enhances energy efficiency by reducing thermal bridging and improving insulation performance due to its seamless design, which minimizes air leakage compared to flat glass. The aerodynamic shape of curved glass optimizes natural light distribution and solar heat gain, contributing to lower heating and cooling costs. In contrast, flat glass typically requires additional framing and sealing, which can compromise thermal performance and increase energy loss.

Versatility in Architectural Applications

Curved glass offers unmatched versatility in architectural applications by enabling complex, dynamic building shapes and enhancing aesthetic appeal with smooth, flowing lines. Flat glass remains essential for straightforward designs and efficient construction, providing cost-effective and easy-to-install solutions. Architects leverage curved glass for innovative facades and interior elements, while flat glass dominates in windows, partitions, and standard glazing systems.

Cost Considerations: Curved vs Flat Glass

Curved glass typically incurs higher costs than flat glass due to specialized manufacturing processes, such as heating and bending, which require advanced equipment and skilled labor. The complexity of shaping and tempering curved glass also extends production time, increasing overall expenses. Flat glass benefits from standardized production techniques, making it more affordable and widely available for various architectural and automotive applications.

Popular Uses in Modern Construction

Curved glass is extensively used in modern architectural facades, enhancing aesthetics and allowing for innovative, aerodynamic building shapes in commercial skyscrapers and luxury residential projects. Flat glass remains the preferred choice for standard window panes, interior partitions, and curtain walls due to its cost-effectiveness and ease of installation. Both materials are crucial in sustainable building designs, with curved glass offering superior light diffusion and flat glass providing excellent thermal insulation.

Choosing the Right Glass for Your Project

Curved glass offers enhanced aesthetic appeal and structural strength, making it ideal for modern architectural designs requiring smooth, flowing lines and panoramic views. Flat glass provides cost-effective versatility, suitable for standard windows, doors, and partitions with straightforward installation and customization options. Selecting the right glass depends on project specifications such as design complexity, budget constraints, and performance requirements like thermal insulation and load-bearing capacity.

Curved glass vs Flat glass Infographic

materialdif.com

materialdif.com