Optical glass features superior clarity and precise refractive indices, making it ideal for lenses, prisms, and high-performance optical devices. Standard glass, commonly used in windows and containers, lacks the specialized purity and consistency required for optimal light transmission and minimal distortion. The specialized manufacturing of optical glass ensures enhanced light focusing and reduced chromatic aberration compared to standard glass.

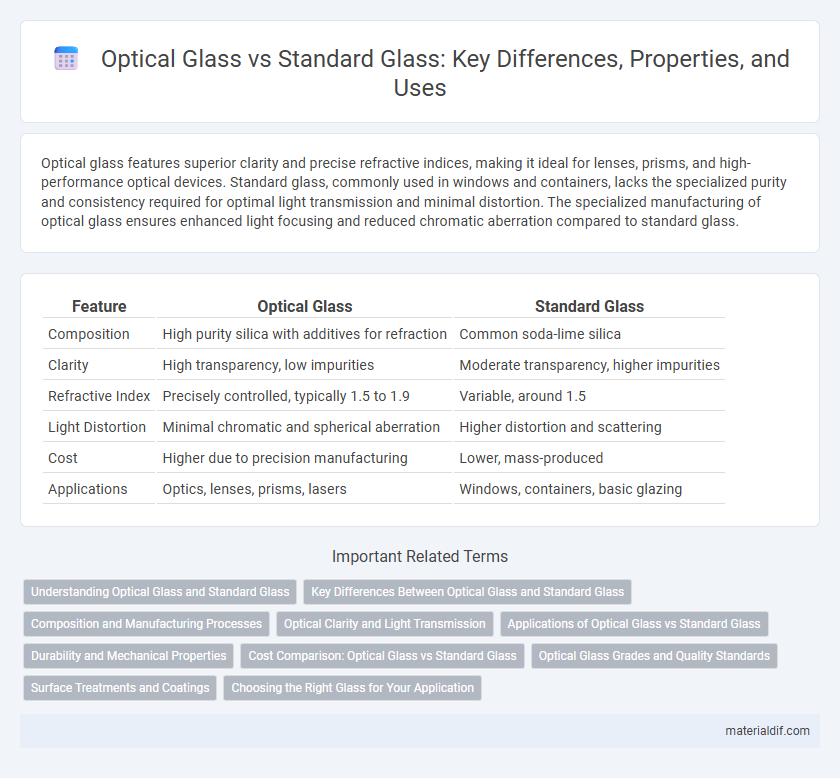

Table of Comparison

| Feature | Optical Glass | Standard Glass |

|---|---|---|

| Composition | High purity silica with additives for refraction | Common soda-lime silica |

| Clarity | High transparency, low impurities | Moderate transparency, higher impurities |

| Refractive Index | Precisely controlled, typically 1.5 to 1.9 | Variable, around 1.5 |

| Light Distortion | Minimal chromatic and spherical aberration | Higher distortion and scattering |

| Cost | Higher due to precision manufacturing | Lower, mass-produced |

| Applications | Optics, lenses, prisms, lasers | Windows, containers, basic glazing |

Understanding Optical Glass and Standard Glass

Optical glass is engineered with precise refractive indices and minimal impurities to enhance light transmission and reduce distortion, making it ideal for lenses and optical instruments. Standard glass, commonly used in windows and containers, has a simpler composition and lacks the precise optical properties, resulting in lower clarity and higher light scattering. Understanding the differences between optical and standard glass is crucial for applications requiring accurate light manipulation and image quality.

Key Differences Between Optical Glass and Standard Glass

Optical glass is engineered for superior clarity, precise light transmission, and minimal distortion, making it essential in lenses, microscopes, and cameras, whereas standard glass is primarily designed for general use like windows and containers with lower optical performance. Optical glass often features controlled refractive indices and higher purity to enhance image quality, contrasting with the more variable composition and lower translucency of standard glass. Additionally, optical glass undergoes specialized manufacturing processes to reduce impurities and defects that can disrupt light paths, unlike standard glass which tolerates more imperfections due to its functional applications.

Composition and Manufacturing Processes

Optical glass differs from standard glass primarily in its precise chemical composition, often containing higher levels of silica and special additives like boron oxide to enhance clarity and refractive properties. Manufacturing optical glass involves stringent melting and cooling processes under controlled temperatures to minimize impurities and internal stresses, ensuring superior optical performance. Standard glass typically uses a simpler soda-lime composition and faster production methods designed for general structural uses rather than high-precision optical applications.

Optical Clarity and Light Transmission

Optical glass exhibits superior optical clarity compared to standard glass due to its low iron content and precise manufacturing processes that minimize impurities and distortions. This enhanced clarity results in higher light transmission rates, typically exceeding 90%, allowing for better color accuracy and sharper image quality. In contrast, standard glass usually has lower light transmission and more visual defects, making it less suitable for applications requiring precision optics.

Applications of Optical Glass vs Standard Glass

Optical glass is primarily used in precision instruments such as cameras, microscopes, telescopes, and eyeglasses due to its superior clarity, controlled refractive indices, and minimal distortion. Standard glass is commonly applied in construction, automotive windows, and everyday containers, where transparency and durability are key but optical precision is less critical. The specialized properties of optical glass enable enhanced light transmission and image quality, making it essential for advanced optical devices compared to the more general-purpose applications of standard glass.

Durability and Mechanical Properties

Optical glass exhibits superior durability and enhanced mechanical properties compared to standard glass, featuring higher resistance to scratching and impact due to its refined chemical composition and precise manufacturing processes. Its increased hardness and tensile strength make it ideal for applications requiring long-term optical clarity and structural integrity, such as lenses and precision instruments. Standard glass, while more affordable, often lacks these advanced properties, leading to greater susceptibility to abrasion and breakage under stress.

Cost Comparison: Optical Glass vs Standard Glass

Optical glass typically incurs higher manufacturing costs due to its precise composition and superior clarity, essential for lenses and precision instruments, whereas standard glass production is more cost-effective and widely used in everyday applications like windows and bottles. The cost disparity is driven by factors such as raw material purity, specialized processing techniques, and stringent quality control required for optical glass. Despite the initial higher investment, optical glass offers enhanced performance and durability, justifying its price in high-precision fields.

Optical Glass Grades and Quality Standards

Optical glass grades such as BK7, Fused Silica, and Crown glass exhibit superior clarity, low dispersion, and precise refractive indices compared to standard glass, essential for high-performance lenses and prisms. Quality standards for optical glass are governed by ISO 10110 and MIL-G-174B, ensuring low inclusions, high homogeneity, and minimal birefringence, critical for accurate light transmission and imaging applications. These stringent specifications differentiate optical glass by optimizing light refraction, minimizing aberrations, and enhancing overall optical performance in scientific and industrial uses.

Surface Treatments and Coatings

Optical glass features specialized surface treatments such as anti-reflective coatings that reduce glare and enhance light transmission, critical for lenses and precision instruments. Standard glass typically has basic coatings or no treatments, offering minimal protection against scratches and reflections. Advanced coatings on optical glass improve durability, reduce surface damage, and optimize visual clarity compared to untreated standard glass.

Choosing the Right Glass for Your Application

Optical glass, designed with precise refractive indices and low dispersion, offers superior clarity and minimal distortion, making it ideal for lenses, microscopes, and other precision instruments. Standard glass, typically soda-lime or float glass, provides economic durability suitable for windows, bottles, and general construction where fine optical quality is not essential. Selecting the right glass depends on application requirements such as optical performance, durability, and cost-effectiveness to ensure optimal functionality.

Optical glass vs Standard glass Infographic

materialdif.com

materialdif.com