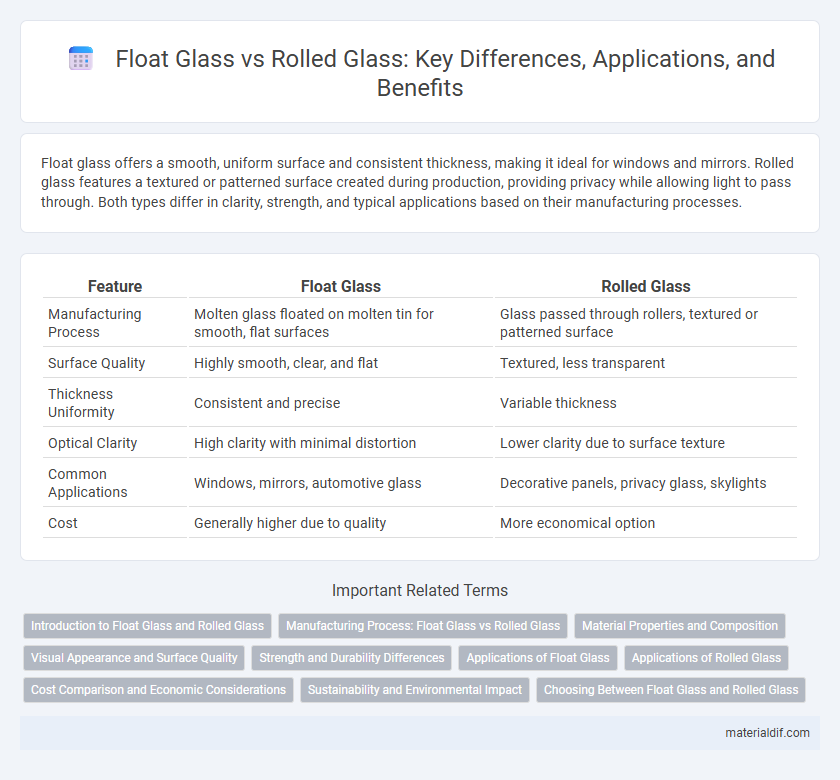

Float glass offers a smooth, uniform surface and consistent thickness, making it ideal for windows and mirrors. Rolled glass features a textured or patterned surface created during production, providing privacy while allowing light to pass through. Both types differ in clarity, strength, and typical applications based on their manufacturing processes.

Table of Comparison

| Feature | Float Glass | Rolled Glass |

|---|---|---|

| Manufacturing Process | Molten glass floated on molten tin for smooth, flat surfaces | Glass passed through rollers, textured or patterned surface |

| Surface Quality | Highly smooth, clear, and flat | Textured, less transparent |

| Thickness Uniformity | Consistent and precise | Variable thickness |

| Optical Clarity | High clarity with minimal distortion | Lower clarity due to surface texture |

| Common Applications | Windows, mirrors, automotive glass | Decorative panels, privacy glass, skylights |

| Cost | Generally higher due to quality | More economical option |

Introduction to Float Glass and Rolled Glass

Float glass is a type of flat glass made by floating molten glass on a bed of molten metal, typically tin, resulting in a smooth, uniform thickness and high optical clarity. Rolled glass, produced by passing molten glass through rollers, has a textured surface and less optical clarity, making it suitable for decorative and privacy applications. The manufacturing processes of float glass and rolled glass define their distinct physical properties, uses, and aesthetic qualities.

Manufacturing Process: Float Glass vs Rolled Glass

Float glass is manufactured by floating molten glass on a bed of molten tin, creating a smooth, uniform thickness and flat surface ideal for windows and mirrors. Rolled glass is produced by passing molten glass through rollers, resulting in textured or patterned surfaces commonly used for decorative or privacy purposes. The float glass process offers higher optical clarity and consistency, while rolled glass allows for greater design versatility through surface textures.

Material Properties and Composition

Float glass features a smooth, uniform surface achieved by floating molten glass on molten tin, resulting in high clarity and consistent thickness, typically composed of silica, soda ash, and limestone. Rolled glass is produced by passing molten glass between rollers, creating textured or patterned surfaces with slightly less optical clarity due to surface irregularities, and contains similar base materials but may include additives to enhance durability and texture. The float glass process yields superior mechanical strength and optical quality ideal for windows and mirrors, while rolled glass offers enhanced privacy and decorative applications due to its patterned finish.

Visual Appearance and Surface Quality

Float glass offers a smooth, uniform surface with excellent optical clarity, making it ideal for applications requiring high visual quality and distortion-free transparency. Rolled glass features a textured or patterned surface due to its manufacturing process, which diffuses light and reduces visibility, enhancing privacy but compromising clarity. Surface imperfections are minimal in float glass, while rolled glass often exhibits slight irregularities and patterns, affecting its overall visual appearance.

Strength and Durability Differences

Float glass offers superior strength and durability due to its uniform thickness and smooth surface, which minimizes stress points and enhances resistance to impact and environmental factors. Rolled glass, characterized by its textured surface and variable thickness, has lower structural integrity and is more susceptible to scratches and breakage under pressure. The manufacturing process of float glass results in consistent density, contributing to its enhanced performance in applications requiring resilience and longevity.

Applications of Float Glass

Float glass offers high optical clarity and uniform thickness, making it ideal for windows, mirrors, and automotive windshields. It is extensively used in architectural glazing due to its smooth surface and strength, providing energy-efficient insulation and sound reduction. Unlike rolled glass, float glass is preferred in applications requiring precise transparency and aesthetic quality.

Applications of Rolled Glass

Rolled glass is extensively used in architectural applications such as skylights, facades, and decorative panels due to its textured surface that diffuses light and enhances privacy. It is ideal for furniture tops and partitions where light transmission is required without clear visibility. Industrial uses include safety glazing and patterned glass for automotive and appliance windows to improve aesthetics and functionality.

Cost Comparison and Economic Considerations

Float glass generally incurs higher manufacturing costs due to its precise production process involving molten glass floated on molten metal, resulting in superior clarity and uniform thickness. Rolled glass is more cost-effective, utilizing a simpler, less energy-intensive process that suits applications where optical quality is less critical. Economic considerations favor float glass for premium architectural projects demanding aesthetic excellence, while rolled glass is preferred for budget-sensitive uses like industrial glazing and decorative surfaces.

Sustainability and Environmental Impact

Float glass production involves a more energy-intensive process than rolled glass, emitting higher greenhouse gases despite its superior surface quality and durability. Rolled glass, made by passing molten glass through rollers, consumes less energy and allows easier recycling, contributing to a smaller carbon footprint. Choosing rolled glass supports sustainability efforts through reduced resource usage and enhanced recyclability in construction and manufacturing.

Choosing Between Float Glass and Rolled Glass

Float glass offers superior optical clarity and smoothness, making it ideal for applications requiring high transparency and flatness such as windows and mirrors. Rolled glass provides textured surfaces and is commonly used for decorative purposes or where privacy is needed, like in shower doors and partitions. Selecting between float and rolled glass depends on the need for clarity, texture, strength, and cost considerations in construction or design projects.

Float glass vs Rolled glass Infographic

materialdif.com

materialdif.com