Tempered glass is created through a heat-treatment process that increases its strength and causes it to shatter into small, blunt pieces upon impact, enhancing safety. Laminated glass consists of two or more layers of glass bonded with an interlayer, providing superior impact resistance and maintaining integrity even when cracked. Choosing between tempered and laminated glass depends on the specific safety, security, and design requirements of the installation.

Table of Comparison

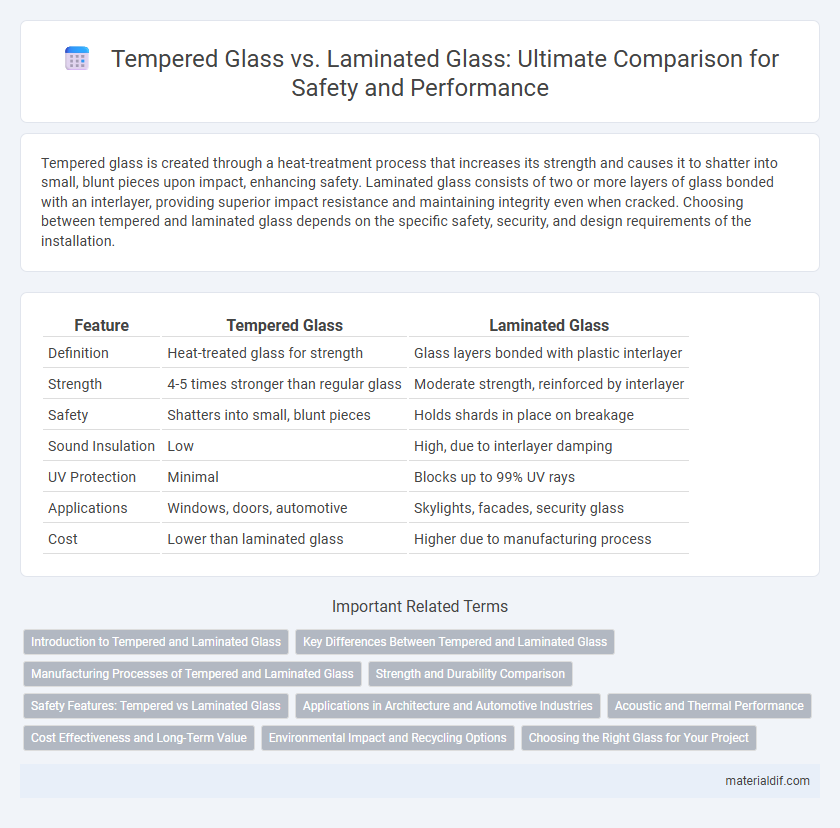

| Feature | Tempered Glass | Laminated Glass |

|---|---|---|

| Definition | Heat-treated glass for strength | Glass layers bonded with plastic interlayer |

| Strength | 4-5 times stronger than regular glass | Moderate strength, reinforced by interlayer |

| Safety | Shatters into small, blunt pieces | Holds shards in place on breakage |

| Sound Insulation | Low | High, due to interlayer damping |

| UV Protection | Minimal | Blocks up to 99% UV rays |

| Applications | Windows, doors, automotive | Skylights, facades, security glass |

| Cost | Lower than laminated glass | Higher due to manufacturing process |

Introduction to Tempered and Laminated Glass

Tempered glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared to normal glass. Laminated glass consists of two or more layers of glass bonded together with an interlayer, typically polyvinyl butyral (PVB), which holds the layers in place if broken. Both types are engineered to improve safety and durability, with tempered glass shattering into small granular pieces and laminated glass maintaining structural integrity when cracked.

Key Differences Between Tempered and Laminated Glass

Tempered glass is heat-treated to enhance its strength and shatters into small, blunt pieces upon impact, minimizing injury risk, while laminated glass consists of two or more glass layers bonded with a plastic interlayer, which holds shards together if broken, providing superior safety and sound insulation. Tempered glass offers higher resistance to thermal stress and impacts but cannot be cut or drilled after tempering, whereas laminated glass maintains structural integrity even when cracked, making it ideal for security and safety applications. The choice between tempered and laminated glass depends on required safety standards, application type, and performance characteristics such as strength, fragmentation pattern, and acoustic properties.

Manufacturing Processes of Tempered and Laminated Glass

Tempered glass undergoes a thermal treatment process where the glass is heated to approximately 620degC and rapidly cooled through air quenching, creating compressive stress on the surface for enhanced strength and safety. Laminated glass is produced by bonding two or more glass layers with an interlayer of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) using heat and pressure through an autoclaving process, which holds the layers together upon impact. The distinct manufacturing processes result in tempered glass shattering into small granular pieces while laminated glass retains its integrity due to the interlayer, providing different safety and durability benefits.

Strength and Durability Comparison

Tempered glass offers superior strength due to its heat-treatment process, making it up to five times stronger than normal glass and highly resistant to impact and thermal stress. Laminated glass, constructed with a polyvinyl butyral (PVB) interlayer, prioritizes durability by holding shards together upon breakage, enhancing safety and structural integrity. While tempered glass excels in resisting direct impacts, laminated glass provides better long-term durability and protection against penetration.

Safety Features: Tempered vs Laminated Glass

Tempered glass offers enhanced safety through its ability to shatter into small, blunt pieces upon impact, reducing the risk of severe injuries. Laminated glass consists of two or more layers of glass bonded with an interlayer that holds shards in place if broken, providing superior protection against penetration and maintaining structural integrity. This makes laminated glass ideal for applications requiring impact resistance and security, while tempered glass suits environments needing thermal and mechanical strength with safer breakage patterns.

Applications in Architecture and Automotive Industries

Tempered glass is widely used in automotive windows and architectural facades due to its high strength and safety features, as it shatters into small, blunt pieces upon impact. Laminated glass, common in windshields and skylights, consists of two or more glass layers bonded with an interlayer that holds fragments together, providing enhanced security and sound insulation. Both types improve building safety and vehicle durability, with tempered glass favored for impact resistance and laminated glass for preventing penetration and noise reduction.

Acoustic and Thermal Performance

Tempered glass offers high strength and safety but provides limited acoustic insulation compared to laminated glass, which features an interlayer that significantly reduces noise transmission. Laminated glass excels in thermal performance by enhancing heat retention and minimizing UV ray penetration, contributing to energy efficiency. For environments prioritizing soundproofing and temperature control, laminated glass is the superior choice over tempered glass.

Cost Effectiveness and Long-Term Value

Tempered glass offers a cost-effective solution due to its lower initial price and high resistance to impact and thermal stress, making it ideal for applications requiring durability. Laminated glass, although more expensive upfront, provides superior safety and noise reduction, enhancing long-term value through increased security and comfort. Choosing laminated glass can result in lower replacement and maintenance costs over time, offering a greater return on investment for safety-critical installations.

Environmental Impact and Recycling Options

Tempered glass, known for its strength and safety features, is fully recyclable and can be melted down repeatedly without loss of quality, making it a more environmentally sustainable choice. Laminated glass contains layers of plastic interlayers that complicate recycling processes due to difficulty in separating materials, often leading to landfill disposal. Choosing tempered glass reduces environmental impact through efficient recycling and lower energy consumption compared to the resource-intensive recycling challenges of laminated glass.

Choosing the Right Glass for Your Project

Tempered glass offers superior strength and safety by shattering into small, blunt pieces, making it ideal for areas with high impact risk such as doors and windows in commercial buildings. Laminated glass consists of two or more layers bonded with an interlayer, providing enhanced sound insulation and security by holding shards in place during breakage, suitable for automotive windshields and skylights. Selecting the right glass depends on factors like safety requirements, soundproofing needs, and project-specific environmental conditions to ensure optimal performance and durability.

Tempered Glass vs Laminated Glass Infographic

materialdif.com

materialdif.com