Chemically strengthened glass undergoes an ion-exchange process that enhances surface compression, making it significantly more resistant to scratches and impacts compared to heat strengthened glass. Heat strengthened glass is produced by controlled cooling after heating, providing roughly twice the strength of annealed glass but less resistance than chemically strengthened varieties. Both types improve safety and durability, yet chemically strengthened glass is preferred in applications requiring superior scratch resistance and higher strength.

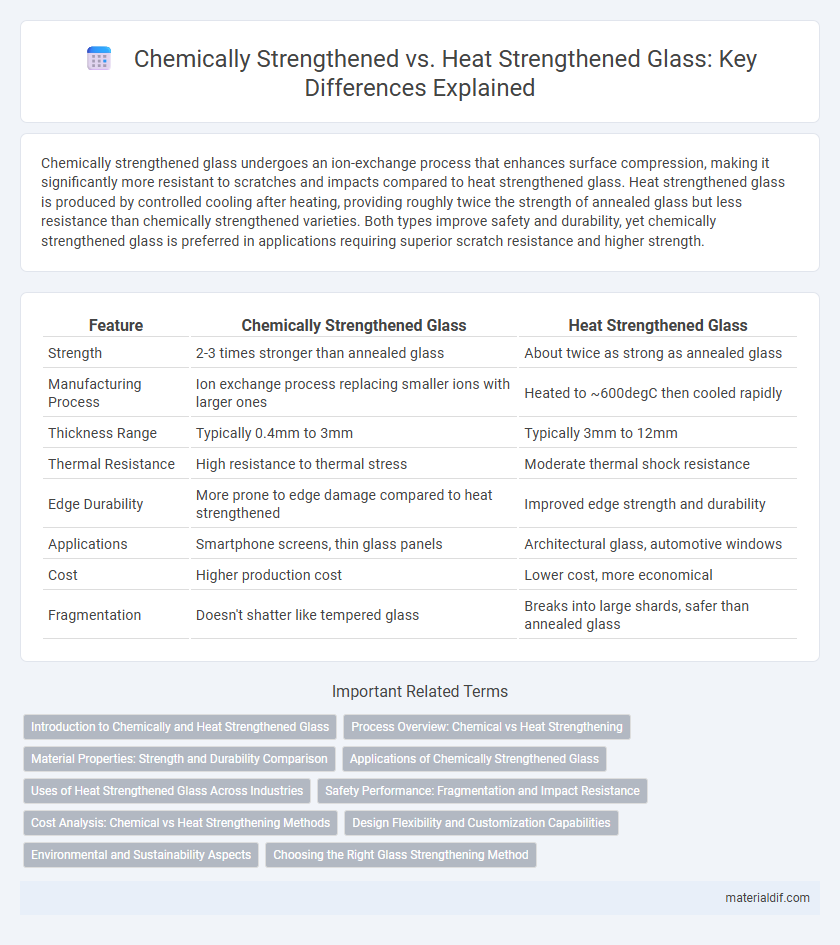

Table of Comparison

| Feature | Chemically Strengthened Glass | Heat Strengthened Glass |

|---|---|---|

| Strength | 2-3 times stronger than annealed glass | About twice as strong as annealed glass |

| Manufacturing Process | Ion exchange process replacing smaller ions with larger ones | Heated to ~600degC then cooled rapidly |

| Thickness Range | Typically 0.4mm to 3mm | Typically 3mm to 12mm |

| Thermal Resistance | High resistance to thermal stress | Moderate thermal shock resistance |

| Edge Durability | More prone to edge damage compared to heat strengthened | Improved edge strength and durability |

| Applications | Smartphone screens, thin glass panels | Architectural glass, automotive windows |

| Cost | Higher production cost | Lower cost, more economical |

| Fragmentation | Doesn't shatter like tempered glass | Breaks into large shards, safer than annealed glass |

Introduction to Chemically and Heat Strengthened Glass

Chemically strengthened glass undergoes an ion-exchange process that replaces smaller sodium ions with larger potassium ions, significantly increasing surface compressive stress and enhancing resistance to scratches and impacts. Heat strengthened glass is produced by controlled thermal tempering, rapidly cooling the glass surface to create moderate compressive stress, which improves strength but offers less durability than chemically strengthened glass. Both types provide improved safety and performance over annealed glass, with chemically strengthened glass favored for applications requiring higher strength and better optical clarity.

Process Overview: Chemical vs Heat Strengthening

Chemical strengthening involves immersing glass in a potassium salt bath at around 400degC, enabling smaller sodium ions on the glass surface to be replaced by larger potassium ions, creating a compressive stress layer that enhances durability. Heat strengthening heats the glass to approximately 620-650degC followed by controlled cooling, which induces moderate compressive stress but less than chemical methods, resulting in improved strength but with less residual stress. Both processes improve glass performance, but chemical strengthening provides superior surface compression and resistance to scratches and impacts.

Material Properties: Strength and Durability Comparison

Chemically strengthened glass undergoes an ion-exchange process that replaces smaller ions with larger ones on the surface, resulting in higher compressive stress and increased strength, typically reaching up to four times the strength of annealed glass. Heat strengthened glass is produced by controlled thermal treatment, providing moderate strength--approximately twice that of annealed glass--while maintaining some ability to break into large fragments upon failure. Chemically strengthened glass offers superior durability and scratch resistance, making it ideal for high-performance applications requiring enhanced toughness and longevity.

Applications of Chemically Strengthened Glass

Chemically strengthened glass is widely used in smartphone screens, automotive glazing, and architectural applications due to its superior scratch resistance and higher tensile strength compared to heat strengthened glass. This glass undergoes an ion exchange process that creates a compressive stress layer, making it more resistant to impact and thermal stress. Its enhanced durability makes it ideal for consumer electronics, storefronts, and heavily trafficked public spaces requiring both safety and clarity.

Uses of Heat Strengthened Glass Across Industries

Heat strengthened glass offers enhanced thermal resistance and increased strength compared to annealed glass, making it suitable for various industrial applications. It is widely used in architectural facades, automotive glazing, and solar panel covers where moderate safety and durability are required without the brittleness of fully tempered glass. This type of glass balances cost-effectiveness and performance, providing a reliable solution for commercial buildings, public transport vehicles, and electronic device screens.

Safety Performance: Fragmentation and Impact Resistance

Chemically strengthened glass undergoes an ion exchange process that creates a deep compression layer, enhancing its impact resistance and producing smaller, less dangerous fragments upon breakage, significantly improving safety performance. Heat strengthened glass, formed by controlled thermal tempering, has moderate residual stress levels that offer better impact resistance than annealed glass but produces larger shards when broken, posing higher fragmentation risks. For applications prioritizing safety in fragmentation and impact resistance, chemically strengthened glass provides superior protection against injury.

Cost Analysis: Chemical vs Heat Strengthening Methods

Chemically strengthened glass typically incurs higher production costs due to the complex ion-exchange process driving enhanced surface compression, whereas heat-strengthened glass involves lower energy consumption through controlled thermal treatment, resulting in moderate expenses. Cost analysis reveals that chemical strengthening demands more specialized equipment and longer processing times, contributing to elevated initial investment compared to heat strengthening's faster cooling techniques. Despite the higher upfront cost, chemically strengthened glass delivers superior strength and scratch resistance, potentially reducing long-term replacement and maintenance expenses.

Design Flexibility and Customization Capabilities

Chemically strengthened glass offers greater design flexibility due to its thinner profile and enhanced surface compression, allowing for more intricate shapes and larger sizes without compromising strength. Heat strengthened glass, while stronger than annealed glass, is thicker and less adaptable to complex customizations, limiting its use in highly specific architectural designs. The superior stress profile of chemically strengthened glass enables innovative design applications, including curved and lightweight facades, making it ideal for projects prioritizing aesthetic versatility and precision engineering.

Environmental and Sustainability Aspects

Chemically strengthened glass involves ion exchange processes that replace smaller sodium ions with larger potassium ions, enhancing durability while consuming less energy than heat treatment methods. Heat strengthened glass undergoes thermal tempering, requiring higher energy input and generating increased carbon emissions compared to chemical strengthening techniques. From an environmental and sustainability perspective, chemically strengthened glass offers a lower carbon footprint and reduced resource consumption, making it a more eco-friendly option for energy-efficient building applications.

Choosing the Right Glass Strengthening Method

Chemically strengthened glass offers superior surface compression through an ion exchange process, resulting in enhanced impact resistance and clarity, ideal for applications requiring high durability and minimal distortion. Heat strengthened glass undergoes controlled thermal treatment, providing moderate strength improvements and better resistance to thermal stress while being more cost-effective for structural uses with less severe impact demands. Selecting the right glass strengthening method depends on performance requirements, budget constraints, and the specific environmental conditions the glass will face.

Chemically Strengthened vs Heat Strengthened Infographic

materialdif.com

materialdif.com