Chemical strengthening enhances glass durability by immersing it in a molten salt bath, allowing smaller ions to be replaced with larger ones, creating compressive stress on the surface. Thermal strengthening involves heating glass to near its softening point followed by rapid cooling, forming a toughened outer surface that improves resistance to impact and thermal stress. Both methods increase glass strength, but chemical strengthening offers better edge strength and optical clarity, while thermal strengthening is more cost-effective for larger glass pieces.

Table of Comparison

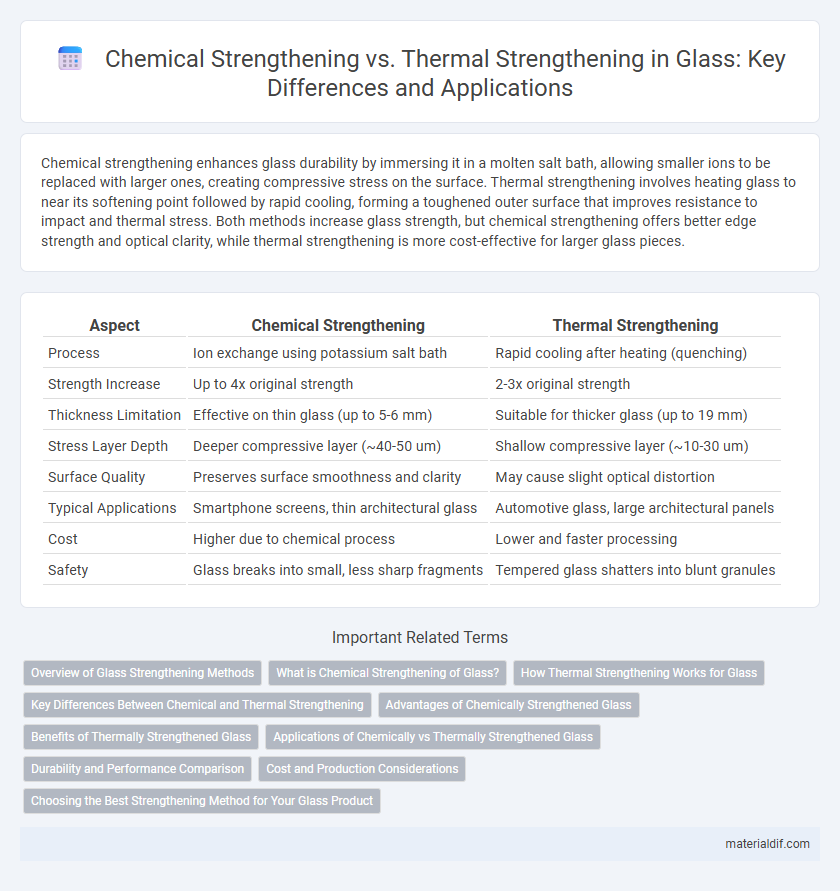

| Aspect | Chemical Strengthening | Thermal Strengthening |

|---|---|---|

| Process | Ion exchange using potassium salt bath | Rapid cooling after heating (quenching) |

| Strength Increase | Up to 4x original strength | 2-3x original strength |

| Thickness Limitation | Effective on thin glass (up to 5-6 mm) | Suitable for thicker glass (up to 19 mm) |

| Stress Layer Depth | Deeper compressive layer (~40-50 um) | Shallow compressive layer (~10-30 um) |

| Surface Quality | Preserves surface smoothness and clarity | May cause slight optical distortion |

| Typical Applications | Smartphone screens, thin architectural glass | Automotive glass, large architectural panels |

| Cost | Higher due to chemical process | Lower and faster processing |

| Safety | Glass breaks into small, less sharp fragments | Tempered glass shatters into blunt granules |

Overview of Glass Strengthening Methods

Chemical strengthening enhances glass durability by immersing it in a molten salt bath, typically potassium nitrate, where smaller sodium ions are replaced by larger potassium ions, creating a compressive stress layer on the surface. Thermal strengthening involves heating the glass to a temperature just below its melting point followed by rapid cooling, inducing surface compression and core tension that improve resistance to mechanical damage. Both methods significantly increase glass strength but vary in depth of compressive layers and suitability for different applications such as smartphone screens or architectural panels.

What is Chemical Strengthening of Glass?

Chemical strengthening of glass involves a process called ion exchange, where smaller ions in the glass are replaced by larger ions from a molten salt bath, creating compressive stress on the surface. This method enhances the glass's resistance to scratches, cracks, and impact without altering its thermal properties. As a result, chemically strengthened glass offers improved durability and safety in applications like smartphone screens and architectural glazing.

How Thermal Strengthening Works for Glass

Thermal strengthening of glass involves heating the glass to a temperature above its annealing point, typically around 600-650degC, and then rapidly cooling its surface through quenching. This process creates compressive stresses on the glass surface while the interior remains in tension, enhancing its strength and resistance to impact and thermal shock. The balance between surface compression and internal tension significantly improves the glass's durability compared to untreated or chemically strengthened glass.

Key Differences Between Chemical and Thermal Strengthening

Chemical strengthening enhances glass durability through an ion-exchange process, replacing smaller ions in the surface layer with larger ones to create compressive stress. Thermal strengthening involves heating glass to a high temperature followed by rapid cooling, resulting in increased surface compression and improved resistance to mechanical stress. Key differences include the depth of the strengthened layer, with chemical strengthening producing a deeper compressive layer and superior resistance to scratches, while thermal strengthening is generally faster and more cost-effective for large, uniform glass sheets.

Advantages of Chemically Strengthened Glass

Chemically strengthened glass offers superior surface compression, enhancing scratch resistance and toughness compared to thermally strengthened glass. This process allows for thinner and lighter glass with equivalent strength, making it ideal for applications in smartphones, tablets, and architectural uses. Its ability to maintain clarity and durability while resisting breakage improves overall product lifespan and user safety.

Benefits of Thermally Strengthened Glass

Thermally strengthened glass offers superior resistance to thermal stress and impact compared to chemically strengthened glass, making it ideal for applications exposed to rapid temperature changes. Its enhanced durability and safety performance result from a controlled thermal tempering process that induces compressive stress, reducing the risk of spontaneous breakage. This type of glass provides a cost-effective balance between strength and optical clarity, suitable for architectural and automotive uses requiring reliable thermal shock resistance.

Applications of Chemically vs Thermally Strengthened Glass

Chemically strengthened glass is widely used in smartphones, tablets, and optical devices due to its superior surface compression and resistance to scratches, enabling ultra-thin, lightweight designs. Thermally strengthened glass is preferred in architectural applications, automotive windows, and solar panels because it offers higher overall strength and impact resistance with enhanced thermal stability. The choice between chemical and thermal strengthening depends on the required balance between surface durability, thickness constraints, and exposure to environmental stresses.

Durability and Performance Comparison

Chemical strengthening enhances glass durability by inducing deep compressive stress through ion exchange, resulting in superior scratch resistance and increased strength compared to thermal strengthening. Thermal strengthening uses rapid heating and controlled cooling to create surface compression but offers lower stress depth, making it less resistant to surface damage. Overall, chemically strengthened glass delivers higher performance in impact resistance and longevity, especially in demanding applications.

Cost and Production Considerations

Chemical strengthening involves ion exchange processes that increase surface compressive stress, resulting in higher strength but requires expensive, time-consuming chemical baths, leading to higher production costs. Thermal strengthening employs controlled heating and rapid cooling to induce surface compression, offering faster processing and lower manufacturing expenses, making it more cost-effective for large-scale production. Choosing between these methods depends on balancing desired glass performance with budget and production speed constraints.

Choosing the Best Strengthening Method for Your Glass Product

Chemical strengthening enhances glass durability by ion exchange, creating a compressive layer that significantly improves resistance to scratches and cracks, ideal for thin or complex-shaped glass products. Thermal strengthening involves controlled heating and rapid cooling, producing moderate strength and improved thermal resistance, suitable for thicker, straightforward glass designs. Selecting the appropriate method depends on the glass product's shape, thickness, and required mechanical strength, balancing performance needs with manufacturing constraints.

Chemical strengthening vs Thermal strengthening Infographic

materialdif.com

materialdif.com