Low-E coating significantly enhances energy efficiency by reflecting infrared light and reducing heat transfer through glass, unlike non-coated glass which allows more heat to pass indoors. This coating minimizes UV damage to interiors and helps maintain comfortable indoor temperatures, lowering heating and cooling costs. Non-coated glass lacks these properties, making it less effective in insulating buildings and protecting furnishings from sun damage.

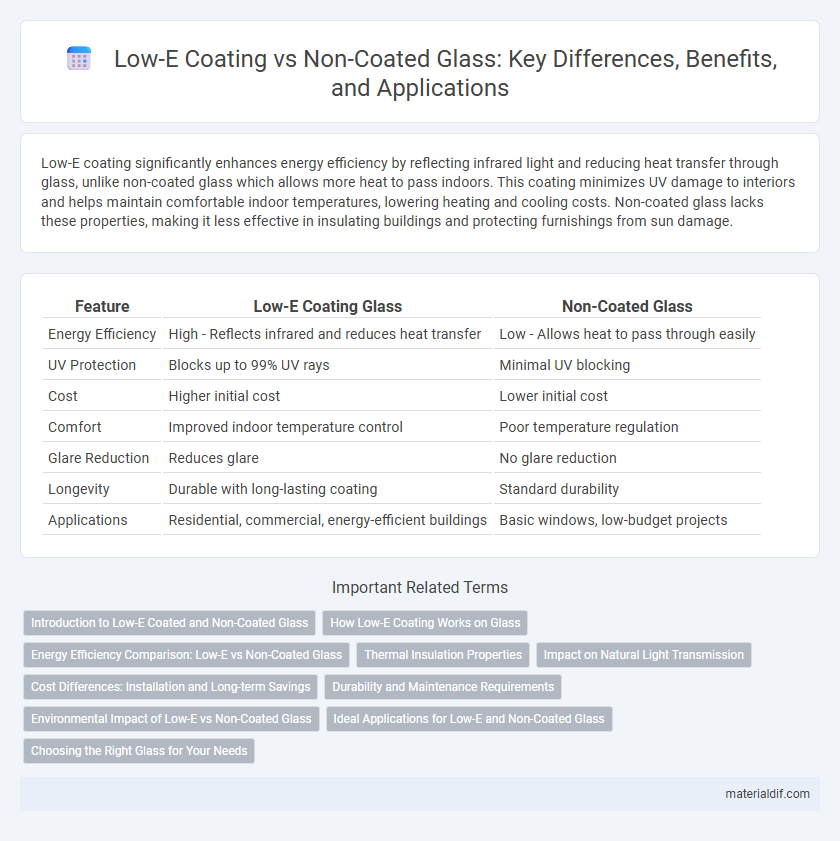

Table of Comparison

| Feature | Low-E Coating Glass | Non-Coated Glass |

|---|---|---|

| Energy Efficiency | High - Reflects infrared and reduces heat transfer | Low - Allows heat to pass through easily |

| UV Protection | Blocks up to 99% UV rays | Minimal UV blocking |

| Cost | Higher initial cost | Lower initial cost |

| Comfort | Improved indoor temperature control | Poor temperature regulation |

| Glare Reduction | Reduces glare | No glare reduction |

| Longevity | Durable with long-lasting coating | Standard durability |

| Applications | Residential, commercial, energy-efficient buildings | Basic windows, low-budget projects |

Introduction to Low-E Coated and Non-Coated Glass

Low-E coated glass features a microscopically thin metallic layer that enhances energy efficiency by reflecting infrared heat while allowing natural light to pass through. Non-coated glass lacks this layer, resulting in higher heat transfer and lower insulation performance. This distinction impacts thermal control, energy savings, and indoor comfort in windows and building facades.

How Low-E Coating Works on Glass

Low-E (low-emissivity) coating on glass works by reflecting infrared energy while allowing visible light to pass through, effectively reducing heat transfer and improving energy efficiency. This microscopic metallic layer minimizes heat loss in winter and heat gain in summer by reflecting interior temperatures back inside and external heat away. Non-coated glass lacks this reflective property, resulting in higher energy consumption and less temperature regulation.

Energy Efficiency Comparison: Low-E vs Non-Coated Glass

Low-E coating significantly enhances glass energy efficiency by reflecting infrared heat while allowing visible light to pass through, reducing heat transfer and lowering heating and cooling costs. Non-coated glass lacks this selective filtering, resulting in greater heat loss during winter and heat gain in summer, which leads to increased energy consumption. Studies show Low-E glass can improve thermal insulation by up to 30%, making it a superior choice for energy-conscious building designs.

Thermal Insulation Properties

Low-E coating significantly enhances the thermal insulation properties of glass by reflecting infrared radiation while allowing visible light to pass through, reducing heat transfer and improving energy efficiency. Non-coated glass lacks this reflective layer, resulting in higher heat loss during winter and heat gain during summer, making it less effective for thermal insulation. Consequently, Low-E coated glass contributes to lower heating and cooling costs in buildings by maintaining more stable indoor temperatures.

Impact on Natural Light Transmission

Low-E coatings significantly reduce heat transfer while maintaining high levels of natural light transmission, typically allowing 70-80% of visible light to pass through compared to non-coated glass, which can permit up to 90%. This selective filtering blocks harmful UV rays and infrared light, enhancing energy efficiency without noticeably dimming interiors. Non-coated glass maximizes natural light but lacks the insulating properties of Low-E coatings, leading to increased heat gain and potential glare.

Cost Differences: Installation and Long-term Savings

Low-E coated glass typically has a higher upfront installation cost compared to non-coated glass due to advanced manufacturing processes and specialized materials. Over time, Low-E coatings enhance energy efficiency by reducing heat transfer, which significantly lowers heating and cooling expenses, leading to substantial long-term savings. Non-coated glass may reduce initial expenses but lacks energy-saving properties, potentially increasing overall utility costs.

Durability and Maintenance Requirements

Low-E coated glass offers superior durability with its thin metal oxide layer that resists scratches and environmental damage compared to non-coated glass. Maintenance requirements for Low-E glass are minimal since the coating helps reduce dirt buildup and prevents UV-induced degradation, extending the lifespan of the window. Non-coated glass typically demands more frequent cleaning and is prone to quicker wear from weather exposure, resulting in higher long-term upkeep costs.

Environmental Impact of Low-E vs Non-Coated Glass

Low-E coated glass significantly reduces energy consumption by reflecting infrared heat while allowing natural light to pass through, decreasing the need for artificial heating and cooling systems. In contrast, non-coated glass allows more heat transfer, leading to higher energy use and greater carbon emissions over the building's lifecycle. The environmental benefits of Low-E coating include lower greenhouse gas emissions and enhanced energy efficiency, making it a more sustainable choice for eco-conscious construction.

Ideal Applications for Low-E and Non-Coated Glass

Low-E coating is ideal for energy-efficient windows in residential and commercial buildings, reducing heat transfer and blocking ultraviolet rays while maximizing daylight. Non-coated glass suits applications where cost-effectiveness and maximum light transmission are priorities, such as interior partitions or decorative uses without thermal insulation needs. Choosing Low-E glass enhances comfort and energy savings, whereas non-coated glass benefits projects with minimal insulation or solar control requirements.

Choosing the Right Glass for Your Needs

Low-E coating significantly improves energy efficiency by reflecting heat while allowing natural light, making it ideal for reducing heating and cooling costs. Non-coated glass provides basic visibility and light transmission but lacks thermal insulation properties, leading to higher energy consumption. Selecting glass depends on your climate, energy goals, and budget, with Low-E glass generally preferred for better comfort and cost savings over time.

Low-E Coating vs Non-Coated Infographic

materialdif.com

materialdif.com