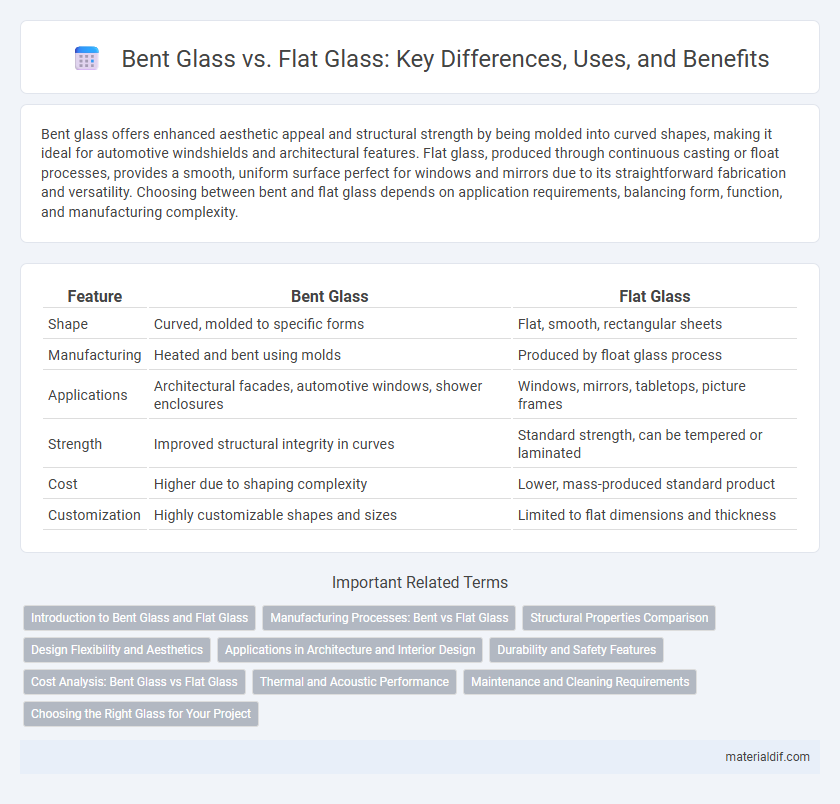

Bent glass offers enhanced aesthetic appeal and structural strength by being molded into curved shapes, making it ideal for automotive windshields and architectural features. Flat glass, produced through continuous casting or float processes, provides a smooth, uniform surface perfect for windows and mirrors due to its straightforward fabrication and versatility. Choosing between bent and flat glass depends on application requirements, balancing form, function, and manufacturing complexity.

Table of Comparison

| Feature | Bent Glass | Flat Glass |

|---|---|---|

| Shape | Curved, molded to specific forms | Flat, smooth, rectangular sheets |

| Manufacturing | Heated and bent using molds | Produced by float glass process |

| Applications | Architectural facades, automotive windows, shower enclosures | Windows, mirrors, tabletops, picture frames |

| Strength | Improved structural integrity in curves | Standard strength, can be tempered or laminated |

| Cost | Higher due to shaping complexity | Lower, mass-produced standard product |

| Customization | Highly customizable shapes and sizes | Limited to flat dimensions and thickness |

Introduction to Bent Glass and Flat Glass

Bent glass is a type of shaped glass that has been heated and molded to form curves and angles, offering enhanced aesthetic and functional possibilities in architectural and automotive applications. Flat glass, also known as float glass, is produced by floating molten glass on a bed of molten metal to create uniform, flat, and smooth panes widely used in windows, mirrors, and tabletops. Key differences include the manufacturing process, visual characteristics, and typical usage scenarios where bent glass enables custom designs while flat glass emphasizes simplicity and cost-effectiveness.

Manufacturing Processes: Bent vs Flat Glass

Bent glass is manufactured by heating flat glass until it softens and then shaping it over molds or forms to achieve curved contours, a process requiring precise temperature control and gradual cooling to maintain structural integrity. Flat glass production involves the float glass process, where molten glass is poured onto a bath of molten tin, creating uniformly flat, smooth sheets as it cools and solidifies. The fundamental difference lies in the post-production shaping for bent glass versus the continuous, uniform surface achieved directly through float glass manufacturing.

Structural Properties Comparison

Bent glass exhibits enhanced structural strength and flexibility compared to flat glass due to its curved shape, which distributes stress more evenly across the surface. This curvature reduces the likelihood of breakage under pressure, making bent glass ideal for applications requiring both durability and aesthetic appeal. Flat glass, while easier to manufacture and cut, is more susceptible to stress concentration and fractures under load, limiting its use in structurally demanding environments.

Design Flexibility and Aesthetics

Bent glass offers superior design flexibility compared to flat glass, enabling architects to create smooth curves and complex shapes that enhance building aesthetics. This material allows for innovative, seamless designs that cannot be achieved with flat glass, providing unique visual appeal and dynamic architectural forms. Flat glass, while more traditional and easier to produce, limits creativity due to its rigidity and planar surface.

Applications in Architecture and Interior Design

Bent glass enhances architectural aesthetics by enabling smooth, curved facades and custom-shaped windows, adding dynamic visual appeal to modern buildings. Flat glass remains essential for traditional applications such as partitions, doors, and windows, providing a cost-effective and versatile option for interior spaces. Both types offer structural and design flexibility, with bent glass often used in high-end projects requiring unique shapes and flat glass favored for straightforward installation and affordability.

Durability and Safety Features

Bent glass offers enhanced durability due to its curved structure, which distributes stress more evenly compared to flat glass, reducing the risk of cracking under impact. Safety features in bent glass often include tempered or laminated treatments, increasing resistance to shattering and making it safer for architectural and automotive applications. In contrast, flat glass is more prone to breakage under stress but can also be strengthened through similar safety processes, though it lacks the inherent stress distribution benefits of bent glass.

Cost Analysis: Bent Glass vs Flat Glass

Bent glass typically incurs higher costs than flat glass due to the specialized manufacturing processes, such as heating and shaping, required to create curved surfaces. Flat glass benefits from mass production techniques that lower material and labor expenses, making it a more economical choice for standard architectural applications. In projects where design complexity demands curvature, the increased expense of bent glass must be weighed against aesthetic or functional benefits.

Thermal and Acoustic Performance

Bent glass enhances thermal performance by reducing heat transfer due to its curved shape, which minimizes air gaps when installed in insulated glazing units. Acoustic insulation improves as bent glass disrupts sound waves more effectively than flat glass, decreasing noise transmission. Flat glass, while cost-effective, generally demonstrates lower thermal resistance and sound dampening capabilities compared to bent glass in architectural applications.

Maintenance and Cleaning Requirements

Bent glass requires specialized cleaning techniques to avoid damaging its curved surface, often necessitating softer, non-abrasive materials and gentle cleaning solutions to maintain clarity and integrity. Flat glass, being more resistant to scratches and easier to access, allows for straightforward cleaning with standard glass cleaners and tools, reducing maintenance time and costs. Both types benefit from regular cleaning schedules, but bent glass demands more careful handling to preserve its shape and optical properties over time.

Choosing the Right Glass for Your Project

Bent glass offers enhanced structural strength and aesthetic appeal through its curved shapes, making it ideal for architectural applications like railings and skylights. Flat glass provides versatility and cost-effectiveness, suitable for windows, mirrors, and tabletops where uniform thickness and smooth surfaces are required. Selecting the right glass depends on project requirements such as design complexity, load-bearing capacity, and budget constraints.

Bent glass vs Flat glass Infographic

materialdif.com

materialdif.com