Glass exhibits varying durability depending on its resistance to alkalis or acids, with alkali-resistant glass designed to withstand corrosive bases that typically degrade silica networks. Acid-resistant glass, often made with higher silica content or specific additives, resists attack from acidic substances that can otherwise dissolve or weaken the glass surface. Choosing the appropriate resistance type depends on the chemical environment, ensuring optimal longevity and performance in applications involving either alkali or acid exposure.

Table of Comparison

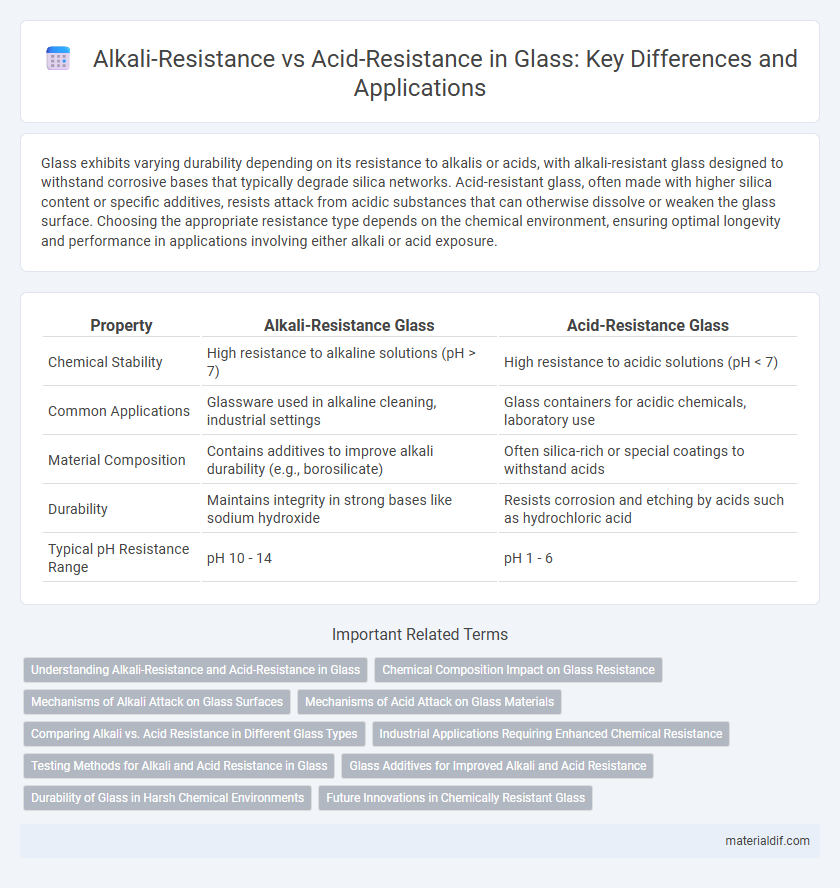

| Property | Alkali-Resistance Glass | Acid-Resistance Glass |

|---|---|---|

| Chemical Stability | High resistance to alkaline solutions (pH > 7) | High resistance to acidic solutions (pH < 7) |

| Common Applications | Glassware used in alkaline cleaning, industrial settings | Glass containers for acidic chemicals, laboratory use |

| Material Composition | Contains additives to improve alkali durability (e.g., borosilicate) | Often silica-rich or special coatings to withstand acids |

| Durability | Maintains integrity in strong bases like sodium hydroxide | Resists corrosion and etching by acids such as hydrochloric acid |

| Typical pH Resistance Range | pH 10 - 14 | pH 1 - 6 |

Understanding Alkali-Resistance and Acid-Resistance in Glass

Alkali-resistant glass, such as borosilicate, withstands high pH environments by resisting chemical attack from alkaline substances, making it ideal for industrial and laboratory applications. Acid-resistant glass, including certain types of fused silica and aluminosilicate, maintains structural integrity and clarity when exposed to strong acids, preventing etching and degradation. Understanding the molecular composition and surface treatment of these glasses is key to selecting the appropriate material for environments with extreme pH levels.

Chemical Composition Impact on Glass Resistance

Glass resistance to alkalis and acids is primarily determined by its chemical composition, with silica-based glasses exhibiting high acid resistance due to the strong Si-O bonds. Borosilicate glass incorporates boron oxide, enhancing alkali resistance by reducing the mobility of alkali ions within the matrix. Aluminosilicate glasses provide balanced resistance against both acidic and alkaline environments by stabilizing the glass network with aluminum oxide.

Mechanisms of Alkali Attack on Glass Surfaces

Alkali attack on glass surfaces primarily involves ion exchange, where alkali ions such as sodium or potassium are leached out and replaced by hydrogen ions from the environment, leading to surface layer disruption. This process results in increased surface roughness, micro-cracking, and reduced mechanical strength due to the breakdown of the silica network. Understanding these mechanisms is critical for improving alkali-resistance coatings and formulations to enhance glass durability in high-pH environments.

Mechanisms of Acid Attack on Glass Materials

Acid attack on glass materials primarily occurs through the leaching of alkali ions from the glass network, disrupting the silicate structure and leading to surface degradation. Hydrogen ions in acidic solutions exchange with network modifiers like sodium and potassium, causing hydrolysis of Si-O-Si bonds and breaking down the glass matrix. This ion-exchange and network dissolution mechanism distinguishes acid resistance from alkali resistance, where alkaline attack targets different structural components and produces varied degradation patterns.

Comparing Alkali vs. Acid Resistance in Different Glass Types

Alkali resistance and acid resistance vary significantly among glass types, with borosilicate glass exhibiting superior alkali resistance due to its low sodium content and high silica network. Soda-lime glass, common in windows and containers, shows moderate acid resistance but is highly susceptible to alkali attack, leading to surface degradation. Aluminosilicate glass provides balanced resistance to both acids and alkalis, making it suitable for harsh chemical environments where durability is critical.

Industrial Applications Requiring Enhanced Chemical Resistance

Alkali-resistant glass is crucial in industrial applications involving exposure to high pH substances like sodium hydroxide, commonly found in chemical processing and wastewater treatment plants. Acid-resistant glass is preferred for environments with strong acids such as sulfuric or hydrochloric acid, making it ideal for pharmaceutical manufacturing and pickling processes. Choosing the right glass type enhances durability and safety by preventing chemical degradation in harsh industrial conditions.

Testing Methods for Alkali and Acid Resistance in Glass

Testing methods for alkali resistance in glass typically involve immersing samples in sodium hydroxide (NaOH) solutions at controlled temperatures, followed by measuring weight loss or surface degradation to assess durability. Acid resistance testing often uses hydrochloric acid (HCl) or sulfuric acid (H2SO4) baths, where the glass is exposed for set durations before analyzing changes in optical clarity and material integrity. Advanced techniques like scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) are employed to detect microstructural alterations and compositional changes after alkaline or acidic exposure.

Glass Additives for Improved Alkali and Acid Resistance

Glass additives such as alumina, zirconia, and titania significantly enhance alkali resistance by forming a more durable network structure that resists degradation in high pH environments. Incorporating tin oxide and silica increases acid resistance by creating a chemically stable surface that limits corrosive attack from acidic substances. Optimizing the concentration and combination of these additives can tailor glass formulations for specific applications requiring robust resistance against both alkaline and acidic conditions.

Durability of Glass in Harsh Chemical Environments

Alkali-resistant glass demonstrates superior durability in environments with high pH levels, maintaining structural integrity and clarity despite prolonged exposure to corrosive alkaline substances. Acid-resistant glass exhibits strong resistance against low pH chemicals, preventing surface etching and degradation when subjected to acidic solutions. The choice between alkali and acid-resistant glass depends on the specific chemical environment to ensure optimal longevity and performance in harsh conditions.

Future Innovations in Chemically Resistant Glass

Future innovations in chemically resistant glass emphasize enhancing alkali-resistance through nano-coatings and advanced ceramic composites, significantly improving durability against harsh environmental conditions. Acid-resistant glass developments focus on integrating fluorinated polymers and hybrid materials to withstand strong acidic attacks without sacrificing transparency. Emerging technologies aim to balance alkali- and acid-resistance, creating multifunctional glass solutions for industrial and architectural applications.

Alkali-resistance vs Acid-resistance Infographic

materialdif.com

materialdif.com