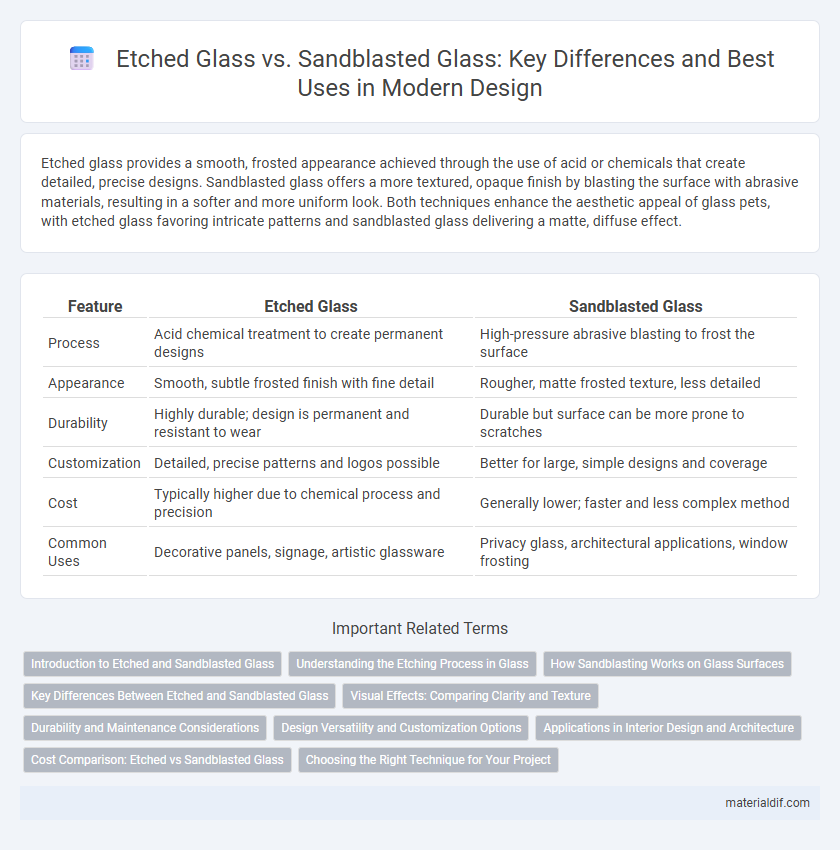

Etched glass provides a smooth, frosted appearance achieved through the use of acid or chemicals that create detailed, precise designs. Sandblasted glass offers a more textured, opaque finish by blasting the surface with abrasive materials, resulting in a softer and more uniform look. Both techniques enhance the aesthetic appeal of glass pets, with etched glass favoring intricate patterns and sandblasted glass delivering a matte, diffuse effect.

Table of Comparison

| Feature | Etched Glass | Sandblasted Glass |

|---|---|---|

| Process | Acid chemical treatment to create permanent designs | High-pressure abrasive blasting to frost the surface |

| Appearance | Smooth, subtle frosted finish with fine detail | Rougher, matte frosted texture, less detailed |

| Durability | Highly durable; design is permanent and resistant to wear | Durable but surface can be more prone to scratches |

| Customization | Detailed, precise patterns and logos possible | Better for large, simple designs and coverage |

| Cost | Typically higher due to chemical process and precision | Generally lower; faster and less complex method |

| Common Uses | Decorative panels, signage, artistic glassware | Privacy glass, architectural applications, window frosting |

Introduction to Etched and Sandblasted Glass

Etched glass involves chemical processes that create precise, intricate designs by selectively removing surface layers for a smooth matte finish. Sandblasted glass uses high-pressure abrasive particles to carve patterns, resulting in a textured, frosted appearance with varying depths of detail. Both techniques enhance privacy and aesthetics in architectural and decorative applications, offering customizable options for light diffusion and design complexity.

Understanding the Etching Process in Glass

Etching glass involves creating a frosted or textured surface by applying acid or abrasive materials to erode the glass layer, resulting in intricate, permanent designs. Sandblasted glass achieves similar effects by propelling fine abrasive particles at high pressure to carve patterns, offering more control over depth and texture. Understanding the etching process is crucial for selecting the ideal technique based on design complexity, durability, and aesthetic preferences in decorative or functional glass applications.

How Sandblasting Works on Glass Surfaces

Sandblasting works on glass surfaces by propelling fine abrasive particles at high velocity to erode and texture the glass, creating a frosted, matte finish. This process offers precise control over depth and pattern, enabling custom designs and uniform coverage on clear or patterned glass. Compared to etched glass, sandblasted glass typically has sharper, more defined edges and greater versatility for both intricate artwork and large-scale surface treatments.

Key Differences Between Etched and Sandblasted Glass

Etched glass is created using acid to corrode the surface, resulting in a smooth, frosted texture, while sandblasted glass is produced by blasting abrasive material at high pressure, creating a more textured and rough finish. Etching allows for more intricate and detailed designs due to the precision of the acid application, whereas sandblasting is better suited for bold, simple patterns because of its broader abrasive impact. Durability-wise, etched glass maintains a clearer appearance over time, as sandblasted surfaces can accumulate dirt in their deeper textures.

Visual Effects: Comparing Clarity and Texture

Etched glass offers a smooth, subtle texture with precise, clean patterns that maintain higher clarity and allow more light transmission. Sandblasted glass features a rougher, matte surface that diffuses light more uniformly but reduces overall transparency and sharpness of details. The choice between the two depends on the desired balance between aesthetic softness and visual clarity in architectural and decorative applications.

Durability and Maintenance Considerations

Etched glass offers superior durability compared to sandblasted glass due to its chemical process that creates a permanently smooth, matte surface resistant to wear and scratches. Sandblasted glass, while providing a textured finish, tends to accumulate dirt and requires more frequent cleaning and careful maintenance to preserve its appearance. Both options need gentle, non-abrasive cleaning methods, but etched glass generally demands less upkeep and maintains clarity longer in high-traffic or outdoor environments.

Design Versatility and Customization Options

Etched glass offers intricate, detailed designs by using acid to create precise patterns, making it ideal for fine artwork and subtle textures. Sandblasted glass provides a more uniform, frosted appearance with the ability to create bold, opaque designs for enhanced privacy and light diffusion. Both techniques allow for extensive customization, but etched glass excels in delicate motifs, while sandblasted glass suits larger, more dramatic design elements.

Applications in Interior Design and Architecture

Etched glass and sandblasted glass both enhance interior design and architecture by offering decorative privacy and textured aesthetics. Etched glass features intricate, precise patterns ideal for elegant partitions, cabinet doors, and office spaces, while sandblasted glass provides a frosted, matte finish suited for large panels, bathroom enclosures, and decorative windows. Designers favor etched glass for detailed artistry and sandblasted glass for uniform opacity and durability in high-traffic areas.

Cost Comparison: Etched vs Sandblasted Glass

Etched glass typically costs more than sandblasted glass due to the precision and detail involved in the acid-etching process, with prices ranging from $150 to $300 per square foot compared to sandblasting's $100 to $250 per square foot. Sandblasted glass offers a more budget-friendly option while still providing frosted, decorative surfaces suitable for windows, doors, and partitions. The choice between etched and sandblasted glass depends on design complexity and project budget, with etched glass favored for intricate patterns and sandblasted glass preferred for broader, less detailed applications.

Choosing the Right Technique for Your Project

Etched glass offers precise, detailed designs created using acid etching, ideal for intricate patterns and branding elements, while sandblasted glass provides a frosted, textured finish suited for privacy and more uniform surfaces. Project requirements such as desired design complexity, budget, and durability should guide the choice between the two methods. Etched glass is often favored for high-end decorative applications, whereas sandblasted glass excels in functional privacy and large-scale design consistency.

Etched glass vs Sandblasted glass Infographic

materialdif.com

materialdif.com