Ultra-thin glass offers exceptional flexibility and lighter weight, making it ideal for modern electronic devices and architectural applications where minimalism and transparency are essential. Thick glass provides superior strength, durability, and thermal insulation, making it suitable for structural elements, safety windows, and environments requiring enhanced security. Selecting between ultra-thin and thick glass depends on balancing the need for aesthetic appeal, functionality, and safety requirements.

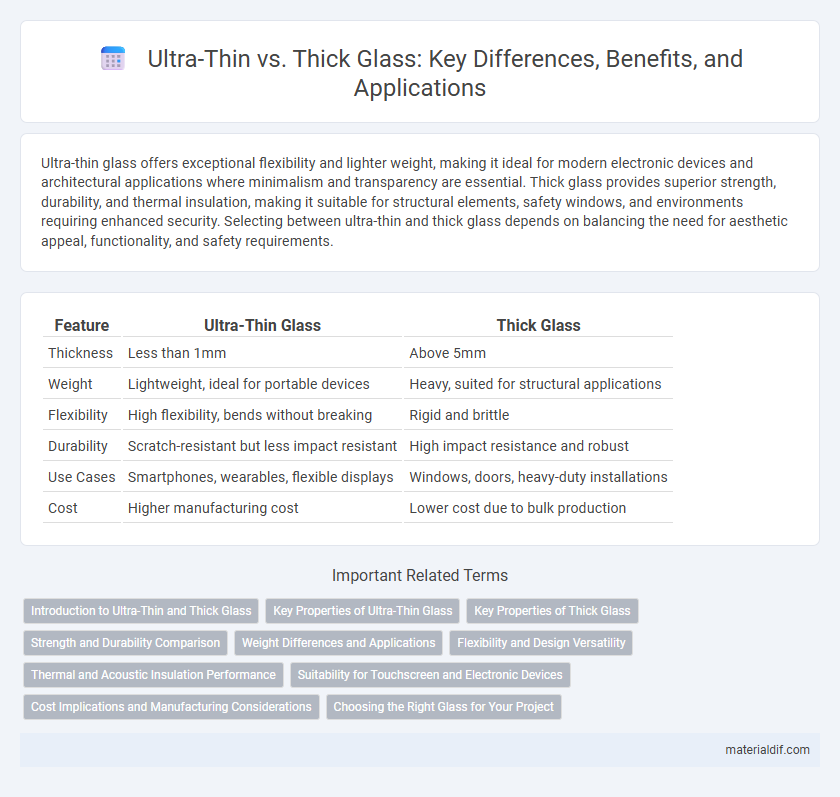

Table of Comparison

| Feature | Ultra-Thin Glass | Thick Glass |

|---|---|---|

| Thickness | Less than 1mm | Above 5mm |

| Weight | Lightweight, ideal for portable devices | Heavy, suited for structural applications |

| Flexibility | High flexibility, bends without breaking | Rigid and brittle |

| Durability | Scratch-resistant but less impact resistant | High impact resistance and robust |

| Use Cases | Smartphones, wearables, flexible displays | Windows, doors, heavy-duty installations |

| Cost | Higher manufacturing cost | Lower cost due to bulk production |

Introduction to Ultra-Thin and Thick Glass

Ultra-thin glass, typically measuring less than 0.5 millimeters in thickness, offers exceptional flexibility and is widely used in advanced electronic displays, flexible screens, and durable wearable devices. Thick glass, often exceeding 6 millimeters, provides enhanced strength, impact resistance, and insulation, making it ideal for architectural applications, safety windows, and heavy-duty protective barriers. Both types serve distinct industry needs by balancing durability, transparency, and functional adaptability in modern material science.

Key Properties of Ultra-Thin Glass

Ultra-thin glass offers exceptional flexibility and lightweight characteristics, making it ideal for advanced electronics and wearable devices. Its high transparency, scratch resistance, and durability ensure superior optical clarity and protection despite its minimal thickness. The thermal and chemical stability of ultra-thin glass enhances device performance and longevity in demanding environments.

Key Properties of Thick Glass

Thick glass offers superior structural strength and enhanced durability, making it ideal for applications requiring impact resistance and load-bearing capacity. Its increased thickness improves sound insulation and thermal performance, providing better energy efficiency and noise reduction in architectural and automotive uses. Additionally, thick glass provides greater safety due to its reduced likelihood of breakage and ability to support heavier weights.

Strength and Durability Comparison

Ultra-thin glass offers exceptional flexibility and lightweight properties but generally falls short in strength and durability compared to thick glass, which provides superior impact resistance and structural integrity for demanding applications. Thick glass withstands higher mechanical stresses and is more resistant to scratches and breakage, making it ideal for construction, automotive, and safety uses. Ultra-thin glass requires advanced treatments like chemical strengthening to enhance its durability, yet thick glass consistently outperforms in maintaining long-term strength under heavy loads.

Weight Differences and Applications

Ultra-thin glass typically weighs significantly less than thick glass, enabling its use in applications requiring lightweight and flexible materials such as smartphones, tablets, and wearable devices. Thick glass provides enhanced durability and impact resistance, making it suitable for architectural windows, automotive windshields, and protective barriers. The choice between ultra-thin and thick glass depends on balancing weight considerations with strength and application-specific performance needs.

Flexibility and Design Versatility

Ultra-thin glass offers superior flexibility, enabling innovative curved and foldable designs ideal for modern smartphones and wearable devices. Thick glass provides enhanced durability and impact resistance, making it suitable for applications requiring robust protection such as architectural panels and heavy-duty screens. The choice between ultra-thin and thick glass depends on balancing design versatility with structural strength for specific use cases.

Thermal and Acoustic Insulation Performance

Ultra-thin glass offers limited thermal and acoustic insulation due to its minimal thickness, which reduces its ability to block heat transfer and sound waves effectively. Thick glass significantly enhances insulation properties by providing a denser barrier that improves heat resistance and sound dampening performance. Applications requiring superior energy efficiency and noise reduction benefit greatly from thick glass compared to ultra-thin alternatives.

Suitability for Touchscreen and Electronic Devices

Ultra-thin glass offers superior sensitivity and responsiveness, making it ideal for touchscreen and electronic devices that require high precision and durability. Thick glass, while providing enhanced strength and impact resistance, often compromises touch sensitivity and adds bulk, making it less suitable for sleek, modern electronic interfaces. Manufacturers prioritize ultra-thin glass in smartphones, tablets, and wearables to optimize user experience and device performance.

Cost Implications and Manufacturing Considerations

Ultra-thin glass requires advanced manufacturing techniques such as precision cutting and tempering, leading to higher production costs compared to thick glass, which benefits from established, cost-effective processes. The fragility and handling challenges of ultra-thin glass increase the risk of breakage, raising quality control expenses. In contrast, thick glass offers greater durability and easier handling, reducing waste and overall manufacturing expenditures.

Choosing the Right Glass for Your Project

Ultra-thin glass offers exceptional flexibility and lightweight properties, making it ideal for applications requiring sleek, modern aesthetics and reduced weight, such as in electronic displays and architectural facades. Thick glass provides superior strength, insulation, and soundproofing, suited for safety barriers, structural elements, and high-impact environments. Selecting the right glass depends on balancing factors like durability, thermal performance, visual clarity, and project-specific requirements for load-bearing or design integration.

Ultra-Thin vs Thick Glass Infographic

materialdif.com

materialdif.com