Laminated glass consists of two or more layers of glass bonded with a plastic interlayer, offering superior impact resistance and enhanced safety as it holds together when shattered. Wired glass incorporates a metal mesh within the glass, providing added fire resistance and preventing glass from falling out during breakage but tends to be less strong against impact and can cause additional injury from sharp wire edges. Choosing between laminated and wired glass depends on whether safety, security, or fire protection is the primary concern in your glass pet display.

Table of Comparison

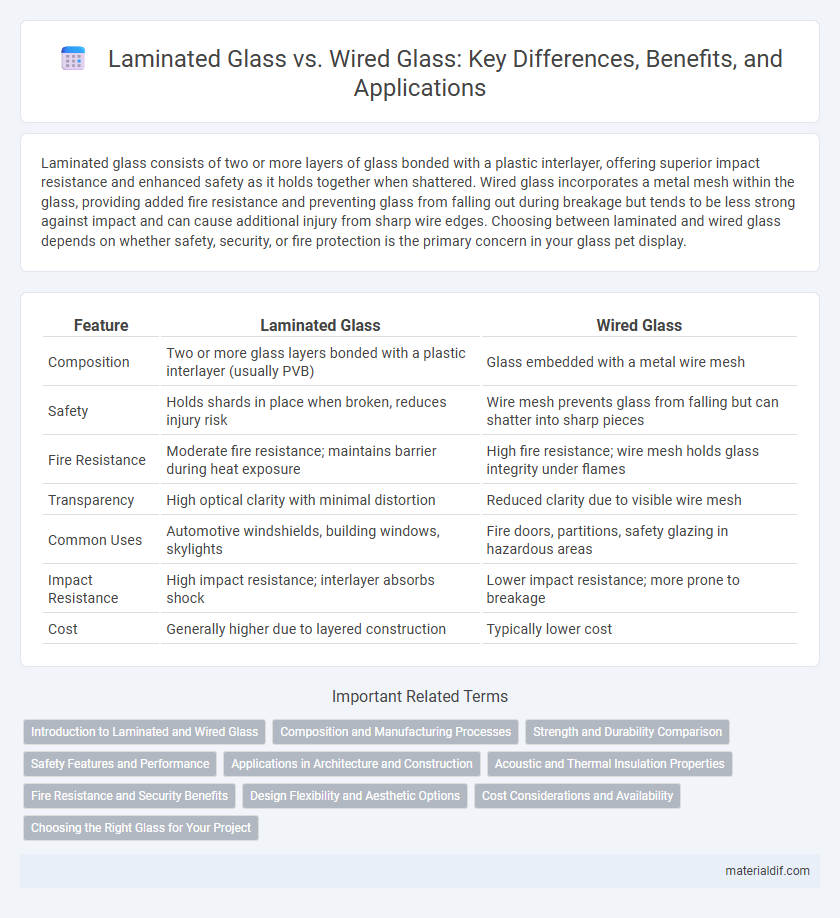

| Feature | Laminated Glass | Wired Glass |

|---|---|---|

| Composition | Two or more glass layers bonded with a plastic interlayer (usually PVB) | Glass embedded with a metal wire mesh |

| Safety | Holds shards in place when broken, reduces injury risk | Wire mesh prevents glass from falling but can shatter into sharp pieces |

| Fire Resistance | Moderate fire resistance; maintains barrier during heat exposure | High fire resistance; wire mesh holds glass integrity under flames |

| Transparency | High optical clarity with minimal distortion | Reduced clarity due to visible wire mesh |

| Common Uses | Automotive windshields, building windows, skylights | Fire doors, partitions, safety glazing in hazardous areas |

| Impact Resistance | High impact resistance; interlayer absorbs shock | Lower impact resistance; more prone to breakage |

| Cost | Generally higher due to layered construction | Typically lower cost |

Introduction to Laminated and Wired Glass

Laminated glass consists of two or more glass layers bonded with an interlayer, typically polyvinyl butyral (PVB), providing enhanced safety by holding shards together upon impact. Wired glass features a mesh of metal wires embedded within the glass, designed primarily for fire resistance and preventing glass from falling out during breakage. Both types serve specific safety functions in architectural and industrial applications, with laminated glass prioritizing impact resistance and wired glass emphasizing fire protection.

Composition and Manufacturing Processes

Laminated glass consists of two or more glass layers bonded with an interlayer, typically polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), created through a heat and pressure lamination process that enhances strength and safety. Wired glass incorporates a mesh of thin steel wires embedded within the glass during the molten stage, improving fire resistance and preventing glass shattering. The manufacturing of laminated glass focuses on layering and curing polymers between glass sheets, while wired glass production involves embedding the wire mesh before cooling the molten glass to solidify the composite structure.

Strength and Durability Comparison

Laminated glass consists of multiple layers of glass bonded with a plastic interlayer, providing superior strength and impact resistance compared to wired glass, which embeds metal wire mesh primarily for fire resistance. The plastic interlayer in laminated glass enhances durability by preventing shattering and holding glass fragments together upon impact, whereas wired glass tends to be more brittle and prone to cracking under stress. Laminated glass is favored in high-security and safety-critical applications due to its ability to withstand stronger forces and maintain structural integrity over time.

Safety Features and Performance

Laminated glass consists of two or more glass layers bonded with a plastic interlayer, providing superior safety by preventing shattering into sharp pieces upon impact, making it ideal for impact resistance and sound insulation. Wired glass contains a mesh of wire embedded within the glass, enhancing fire resistance and holding fragments together during breakage, though it can be more prone to brittle fracture. Laminated glass generally offers better overall performance in terms of durability, security, and safety in both residential and commercial applications.

Applications in Architecture and Construction

Laminated glass is widely used in architectural applications requiring enhanced safety and sound insulation, such as storefronts, skylights, and facades, due to its ability to hold shards together upon impact. Wired glass, traditionally favored for fire-rated windows and partitions, provides heat resistance and prevents glass from shattering, making it suitable for stairwells and electrical enclosures. Modern construction trends increasingly prioritize laminated glass for its aesthetic versatility and improved performance, although wired glass remains relevant where fire code compliance is critical.

Acoustic and Thermal Insulation Properties

Laminated glass offers superior acoustic insulation due to its interlayer that dampens sound vibrations, making it ideal for noise reduction in residential and commercial spaces. Its thermal insulation properties are enhanced by the interlayer, which helps to reduce heat transfer and improve energy efficiency. Wired glass, while providing safety benefits through its embedded wire mesh, generally has inferior acoustic and thermal insulation compared to laminated glass, as the mesh can transmit sound and heat more readily.

Fire Resistance and Security Benefits

Laminated glass offers superior fire resistance by maintaining structural integrity under high temperatures due to its interlayer that holds shards together, preventing dangerous debris during a fire. Wired glass, traditionally used for fire-rated applications, contains embedded wire mesh that resists heat and flames but can shatter into hazardous pieces upon impact. In security terms, laminated glass provides enhanced protection against forced entry through its multiple layers, while wired glass is more vulnerable to breakage despite its fire-resistant qualities.

Design Flexibility and Aesthetic Options

Laminated glass offers superior design flexibility with the ability to incorporate multiple layers, colors, and interlayers, creating diverse aesthetic options such as tinted, patterned, or decorative finishes. Wired glass, while providing enhanced fire resistance and safety due to embedded wire mesh, is limited in visual appeal and design versatility. Architects and designers often prefer laminated glass for modern applications where clarity and customization are critical.

Cost Considerations and Availability

Laminated glass typically incurs higher costs due to its multi-layer construction and enhanced safety features, making it more expensive than wired glass. Wired glass, often used for fire-rated applications, is generally more affordable and widely available in standard sizes and thicknesses. Availability of laminated glass can be limited by customization requirements, whereas wired glass is more commonly stocked by suppliers, impacting project timelines and budget planning.

Choosing the Right Glass for Your Project

Laminated glass offers superior safety by holding shards together upon impact, making it ideal for windows and skylights in high-traffic or security-sensitive areas. Wired glass features embedded metal mesh for fire resistance and structural integrity, but its fragments can pose safety risks if broken. Selecting the right glass depends on balancing safety requirements, fire codes, and aesthetic preferences specific to your project's environment.

Laminated glass vs Wired glass Infographic

materialdif.com

materialdif.com