Coated glass offers enhanced durability and resistance to scratches, fingerprints, and UV damage compared to uncoated glass, making it ideal for long-term use. The coating also improves clarity and reduces glare, providing a better visual experience for glass pets. Uncoated glass, while generally more affordable, is more susceptible to wear and requires careful handling to maintain its appearance and integrity.

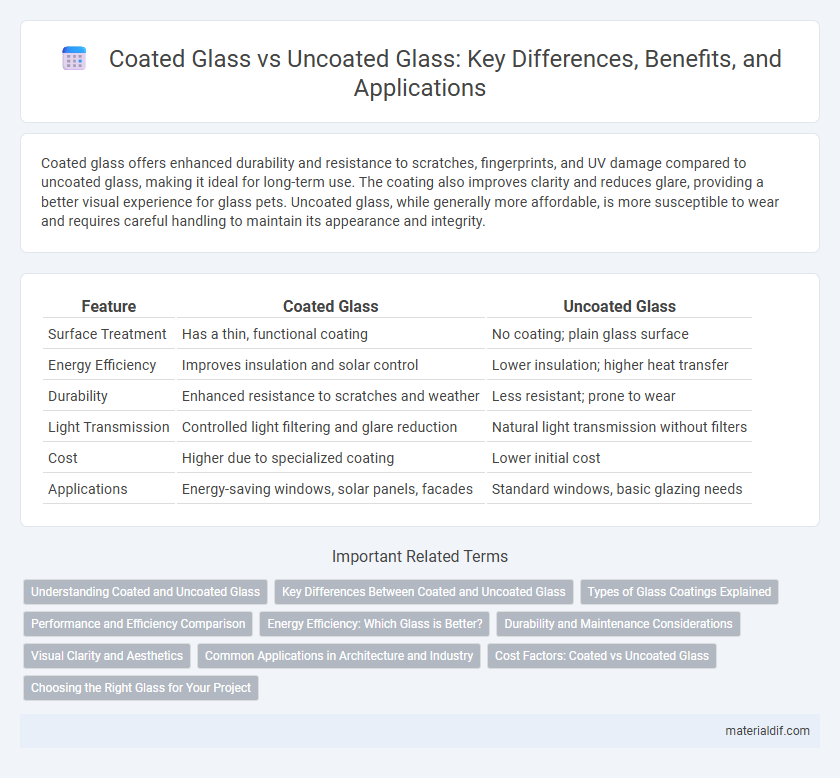

Table of Comparison

| Feature | Coated Glass | Uncoated Glass |

|---|---|---|

| Surface Treatment | Has a thin, functional coating | No coating; plain glass surface |

| Energy Efficiency | Improves insulation and solar control | Lower insulation; higher heat transfer |

| Durability | Enhanced resistance to scratches and weather | Less resistant; prone to wear |

| Light Transmission | Controlled light filtering and glare reduction | Natural light transmission without filters |

| Cost | Higher due to specialized coating | Lower initial cost |

| Applications | Energy-saving windows, solar panels, facades | Standard windows, basic glazing needs |

Understanding Coated and Uncoated Glass

Coated glass features a thin layer of metal or metallic oxide applied to its surface, enhancing properties such as solar control, thermal insulation, and glare reduction. Uncoated glass lacks this layer, resulting in standard transparency and minimal energy performance benefits. Selecting coated glass improves energy efficiency in buildings by reducing heat transfer and UV radiation compared to uncoated glass.

Key Differences Between Coated and Uncoated Glass

Coated glass features a thin layer of metal or metal oxide that enhances its thermal insulation, UV protection, and glare reduction, while uncoated glass lacks these treatments and offers basic transparency. The coating improves energy efficiency by reflecting infrared radiation and controlling solar heat gain, making coated glass ideal for sustainable building applications. Uncoated glass, though more affordable, does not provide the enhanced durability or performance benefits found in coated variants, often limiting its use in specialized construction or automotive contexts.

Types of Glass Coatings Explained

Types of glass coatings include anti-reflective, low-emissivity (Low-E), and self-cleaning coatings, each designed to enhance performance and durability. Anti-reflective coatings reduce glare and improve visibility, while Low-E coatings improve thermal insulation by reflecting infrared light, helping to maintain indoor temperature. Self-cleaning coatings use photocatalytic and hydrophilic properties to break down organic dirt and make water spread evenly, reducing maintenance needs.

Performance and Efficiency Comparison

Coated glass enhances thermal insulation by reflecting infrared radiation, significantly reducing heat transfer and improving energy efficiency compared to uncoated glass. It also offers superior UV protection, minimizing interior fading and heat buildup, while uncoated glass allows greater solar heat gain and less glare control. The advanced performance of coated glass contributes to lower cooling and heating costs, making it a preferred choice for energy-conscious building designs.

Energy Efficiency: Which Glass is Better?

Coated glass significantly improves energy efficiency by reducing heat transfer through its low-emissivity (Low-E) coatings, which reflect infrared energy while allowing visible light to pass. Uncoated glass lacks these specialized coatings and offers minimal insulation, resulting in higher energy loss and increased heating or cooling costs. Consequently, coated glass is the superior choice for energy efficiency in residential and commercial buildings.

Durability and Maintenance Considerations

Coated glass features a thin layer of metal or metal oxide that enhances durability by providing resistance to scratches, weathering, and UV radiation, reducing the need for frequent maintenance. Uncoated glass lacks these protective layers, making it more susceptible to surface damage and requiring more regular cleaning and upkeep to preserve clarity and performance. Choosing coated glass can lead to long-term cost savings and improved longevity in applications exposed to harsh environmental conditions.

Visual Clarity and Aesthetics

Coated glass enhances visual clarity by minimizing glare and reflections through specialized metallic or dielectric layers, resulting in sharper and more vibrant images. Uncoated glass often exhibits higher light reflection, which can reduce transparency and cause distracting visual distortions. Aesthetically, coated glass offers a sleek, modern appearance with options for tinted or mirrored finishes, while uncoated glass maintains a more natural, untreated look that may suit traditional designs.

Common Applications in Architecture and Industry

Coated glass is widely used in architectural applications such as energy-efficient windows, solar control glazing, and low-emissivity (Low-E) facades due to its enhanced thermal insulation and light-reflective properties. Uncoated glass commonly appears in interior partitions, display cases, and decorative elements where natural transparency and cost-effectiveness are prioritized. In industrial settings, coated glass serves in photovoltaic panels and automotive windshields, while uncoated glass is preferred for laboratory equipment and ordinary glazing needs.

Cost Factors: Coated vs Uncoated Glass

Coated glass generally incurs higher costs due to the additional manufacturing processes involving thin-film coatings that enhance properties like UV protection, heat reflection, and glare reduction. Uncoated glass remains more affordable because it lacks these specialized treatments, making it suitable for basic applications without performance enhancements. Cost factors also include long-term energy savings from coated glass, which can offset initial expenses through improved insulation and reduced HVAC demands.

Choosing the Right Glass for Your Project

Coated glass offers enhanced energy efficiency and UV protection by applying a thin layer of metal oxide, making it ideal for projects requiring insulation and glare reduction. Uncoated glass provides natural clarity and is often preferred for applications where optical purity and cost-effectiveness are priorities. Selecting between coated and uncoated glass depends on project-specific needs such as thermal performance, light transmission, and budget constraints.

Coated glass vs Uncoated glass Infographic

materialdif.com

materialdif.com