Chemical strengthened glass undergoes an ion-exchange process that replaces smaller ions with larger ones in the surface layer, resulting in higher compressive stress and superior strength compared to heat strengthened glass. Heat strengthened glass is produced by controlled thermal tempering, offering moderate strength improvement and better resistance to thermal stress but less impact resistance than chemically strengthened glass. Choosing between the two depends on application requirements, with chemical strengthening ideal for thin, high-performance glass and heat strengthening suited for architectural uses needing improved durability without full tempering.

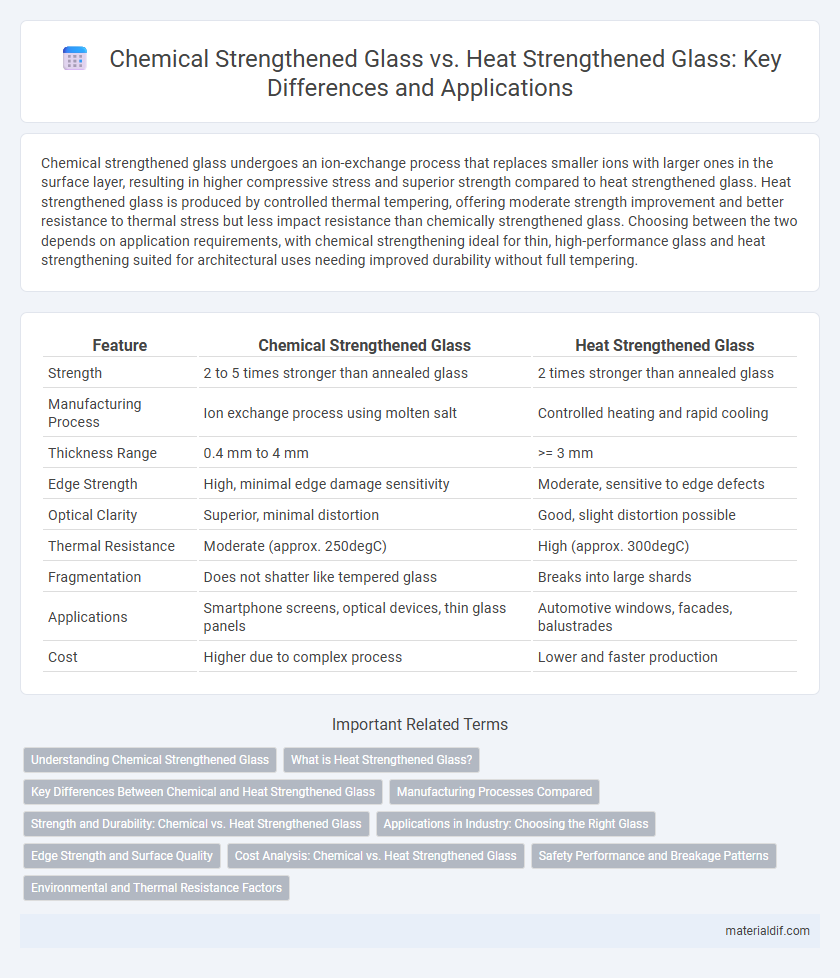

Table of Comparison

| Feature | Chemical Strengthened Glass | Heat Strengthened Glass |

|---|---|---|

| Strength | 2 to 5 times stronger than annealed glass | 2 times stronger than annealed glass |

| Manufacturing Process | Ion exchange process using molten salt | Controlled heating and rapid cooling |

| Thickness Range | 0.4 mm to 4 mm | >= 3 mm |

| Edge Strength | High, minimal edge damage sensitivity | Moderate, sensitive to edge defects |

| Optical Clarity | Superior, minimal distortion | Good, slight distortion possible |

| Thermal Resistance | Moderate (approx. 250degC) | High (approx. 300degC) |

| Fragmentation | Does not shatter like tempered glass | Breaks into large shards |

| Applications | Smartphone screens, optical devices, thin glass panels | Automotive windows, facades, balustrades |

| Cost | Higher due to complex process | Lower and faster production |

Understanding Chemical Strengthened Glass

Chemical strengthened glass undergoes an ion-exchange process where smaller sodium ions in the glass surface are replaced by larger potassium ions, creating a compressive stress layer that significantly enhances its strength and resistance to scratches and cracks. This type of glass typically achieves surface compressive stresses up to 690 MPa, making it stronger than heat strengthened glass, which relies on thermal tempering with compressive stresses around 70-150 MPa. Due to its high strength and clarity retention, chemical strengthened glass is commonly used in applications requiring durable yet optically clear glass, such as smartphone screens, eyewear lenses, and architectural facades.

What is Heat Strengthened Glass?

Heat strengthened glass is a type of safety glass processed by heating annealed glass to approximately 650degC and then cooling it rapidly, resulting in increased strength--approximately twice that of regular annealed glass. It offers improved resistance to thermal stress and moderate mechanical impact, making it suitable for applications such as facades, balustrades, and curtain walls where enhanced durability is required but full tempered strength is unnecessary. Unlike chemically strengthened glass, which achieves strength through ion exchange processes, heat strengthened glass relies on thermal tempering that creates compressive stress on the glass surface to enhance performance.

Key Differences Between Chemical and Heat Strengthened Glass

Chemical strengthened glass undergoes an ion-exchange process where smaller sodium ions are replaced by larger potassium ions, creating compressive stress and resulting in higher strength compared to heat strengthened glass. Heat strengthened glass is produced by controlled cooling after heating, which induces moderate compressive stress but offers only about twice the strength of annealed glass, whereas chemical strengthening can increase strength up to four times. Chemical strengthened glass provides superior edge strength and resistance to surface damage, making it ideal for applications requiring enhanced durability and safety.

Manufacturing Processes Compared

Chemical strengthened glass undergoes an ion-exchange process where smaller sodium ions in the glass surface are replaced by larger potassium ions from a molten salt bath, creating a compressive stress layer that enhances strength. Heat strengthened glass is manufactured by heating the glass to a temperature just below its melting point followed by rapid cooling, producing moderate tensile stress on the surface that increases durability but to a lesser extent than chemical strengthening. The chemical process offers deeper compressive layers and higher strength, while heat strengthening is faster and less costly but results in comparatively lower mechanical performance.

Strength and Durability: Chemical vs. Heat Strengthened Glass

Chemical strengthened glass offers superior surface compression up to 690 MPa, resulting in enhanced strength and resistance to scratches compared to heat strengthened glass, which typically achieves around 150 MPa compressive stress. The deeper compression layer in chemical strengthening, often up to 40 microns, significantly improves durability against mechanical impacts and thermal stress, surpassing heat strengthened glass with a shallower layer of about 3-5 microns. This makes chemically strengthened glass more suitable for high-performance applications requiring maximum strength and longevity.

Applications in Industry: Choosing the Right Glass

Chemical strengthened glass offers superior surface compressive stress, making it ideal for high-impact applications like smartphone screens, aerospace windows, and automotive glazing. Heat strengthened glass, with moderate strength and better thermal resistance, suits architectural uses such as building facades, skylights, and curtain walls. Selecting the appropriate glass depends on balancing impact resistance, thermal performance, and safety requirements specific to industries like electronics, construction, and transportation.

Edge Strength and Surface Quality

Chemical strengthened glass offers superior edge strength due to its deep ion-exchange process, creating a highly compressive layer that significantly reduces the risk of edge damage. Heat strengthened glass undergoes a thermal tempering process that improves edge strength moderately but typically exhibits lower surface quality with more visible distortions. The smoother surface quality of chemical strengthened glass makes it ideal for applications requiring optical clarity and durability, whereas heat strengthened glass is often selected for cost-effective solutions with enhanced mechanical properties.

Cost Analysis: Chemical vs. Heat Strengthened Glass

Chemical strengthened glass typically incurs higher production costs due to its ion-exchange process, which enhances surface compression more effectively than heat strengthened glass. Heat strengthened glass involves thermal treatment that is less expensive but offers lower strength and durability compared to chemical strengthening. In cost analysis, chemical strengthened glass demands higher initial investment but provides better performance and longer lifespan, potentially reducing maintenance and replacement expenses over time.

Safety Performance and Breakage Patterns

Chemical strengthened glass exhibits superior safety performance due to its higher compressive stress layer, reducing the likelihood of spontaneous breakage compared to heat strengthened glass. Upon breakage, chemical strengthened glass tends to fracture into smaller, less hazardous shards, enhancing user safety, whereas heat strengthened glass breaks into larger, more jagged pieces with greater injury potential. The enhanced molecular structure of chemical strengthening allows for improved impact resistance and durability, making it more suitable for high-risk safety applications.

Environmental and Thermal Resistance Factors

Chemical strengthened glass offers superior environmental resistance due to its deeper compressive stress layer, enhancing durability against surface damage and thermal variations. This type of glass withstands higher temperature fluctuations without compromising structural integrity, making it optimal for environments with rapid temperature changes. Heat strengthened glass provides moderate thermal resistance but is more vulnerable to environmental factors such as abrasion and chemical exposure compared to chemically strengthened alternatives.

Chemical strengthened glass vs Heat strengthened glass Infographic

materialdif.com

materialdif.com