Optical glass is engineered for high precision and clarity, optimizing light transmission and minimizing distortions in lenses, microscopes, and optical instruments. Display glass prioritizes durability, scratch resistance, and touch sensitivity, making it ideal for smartphones, tablets, and LCD screens. While both types require transparency, their specific manufacturing processes and material compositions differ to meet distinct functional demands.

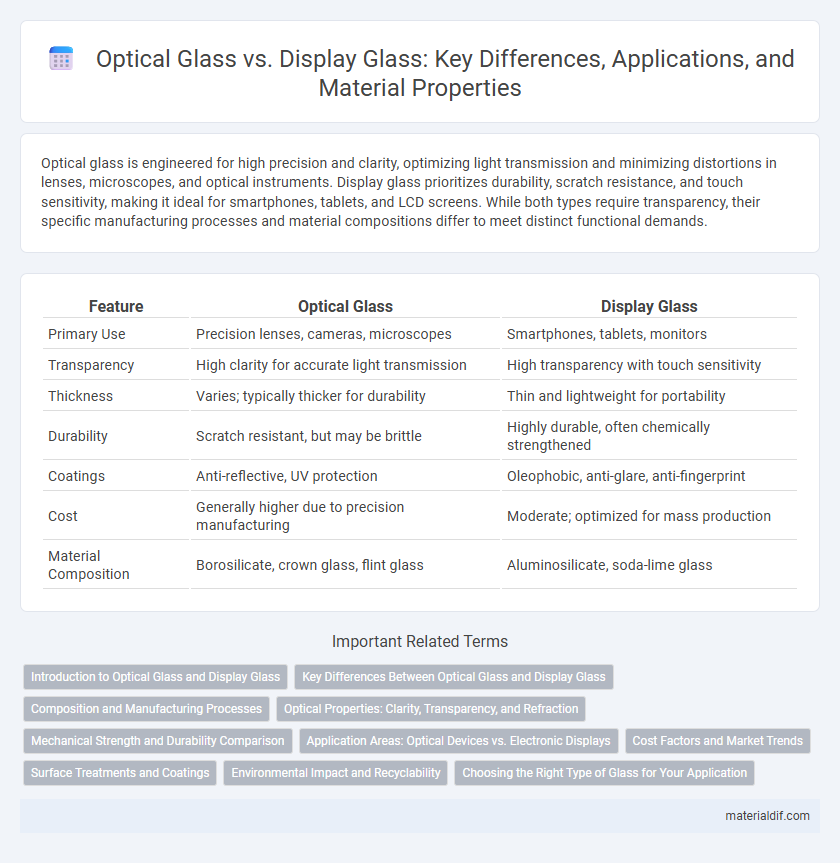

Table of Comparison

| Feature | Optical Glass | Display Glass |

|---|---|---|

| Primary Use | Precision lenses, cameras, microscopes | Smartphones, tablets, monitors |

| Transparency | High clarity for accurate light transmission | High transparency with touch sensitivity |

| Thickness | Varies; typically thicker for durability | Thin and lightweight for portability |

| Durability | Scratch resistant, but may be brittle | Highly durable, often chemically strengthened |

| Coatings | Anti-reflective, UV protection | Oleophobic, anti-glare, anti-fingerprint |

| Cost | Generally higher due to precision manufacturing | Moderate; optimized for mass production |

| Material Composition | Borosilicate, crown glass, flint glass | Aluminosilicate, soda-lime glass |

Introduction to Optical Glass and Display Glass

Optical glass is engineered for precision light refraction, commonly used in lenses, microscopes, and cameras to enhance image clarity and accuracy. Display glass, designed for screens in smartphones, tablets, and TVs, prioritizes durability, touch sensitivity, and high transparency to support vibrant visuals and user interaction. Both types utilize specialized compositions tailored to their respective functions, emphasizing properties like refractive index for optical glass and scratch resistance for display glass.

Key Differences Between Optical Glass and Display Glass

Optical glass is engineered for high clarity, precise light refraction, and minimal distortion, enabling superior image quality in lenses and optical instruments. Display glass, such as Gorilla Glass, is designed primarily for durability, scratch resistance, and touch sensitivity in electronic devices like smartphones and tablets. The key differences lie in their composition, with optical glass emphasizing purity and refractive index, while display glass prioritizes toughness and thinness.

Composition and Manufacturing Processes

Optical glass is primarily composed of silica, boron oxide, and various metal oxides, engineered for high refractive index and minimal dispersion through precise melting and controlled annealing processes. Display glass typically includes aluminosilicate or soda-lime compositions, optimized for strength and scratch resistance via chemical tempering and tempering techniques like ion exchange. Manufacturing optical glass involves careful refining to ensure clarity and optical performance, while display glass emphasizes surface durability and impact resistance during mass production.

Optical Properties: Clarity, Transparency, and Refraction

Optical glass exhibits superior clarity and high transparency, enabling precise light transmission with minimal distortion, essential for lenses and scientific instruments. Display glass, while transparent, is optimized for durability and touch sensitivity, sometimes sacrificing slight optical purity to enhance user interaction. The refraction index in optical glass is carefully controlled to reduce chromatic aberration, whereas display glass prioritizes consistent light diffusion to maintain screen brightness and color accuracy.

Mechanical Strength and Durability Comparison

Optical glass exhibits superior mechanical strength due to its high resistance to impact and scratching, making it ideal for precision lenses and scientific instruments. Display glass, such as Gorilla Glass, is engineered for enhanced durability and flexibility, providing robust protection against everyday wear, drops, and bending in smartphones and tablets. While optical glass prioritizes clarity and hardness, display glass balances toughness and lightweight properties to withstand frequent handling and environmental stresses.

Application Areas: Optical Devices vs. Electronic Displays

Optical glass is engineered to enhance light transmission and minimize distortion, making it ideal for lenses in cameras, microscopes, and telescopes where precise image clarity is crucial. Display glass, such as Gorilla Glass, is designed for durability, scratch resistance, and touch sensitivity, supporting the high-resolution screens of smartphones, tablets, and televisions. The application areas diverge as optical glass excels in scientific and imaging instruments, while display glass is optimized for electronic devices requiring robust, transparent protection and responsive user interfaces.

Cost Factors and Market Trends

Optical glass typically incurs higher production costs due to its precision manufacturing requirements and specialized coatings, while display glass benefits from large-scale production and material innovations that reduce expenses. Market trends indicate growing demand for display glass driven by the expansion of smartphones, tablets, and flexible screens, whereas optical glass remains essential in high-end lenses and scientific instruments with steadier, niche demand. Cost factors include raw material quality, manufacturing complexity, and technological advancements influencing pricing and adoption in their respective markets.

Surface Treatments and Coatings

Optical glass typically features anti-reflective coatings and scratch-resistant surface treatments to enhance clarity and durability in lenses and precision instruments. Display glass incorporates oleophobic and anti-fingerprint coatings alongside anti-glare treatments, optimizing touch sensitivity and visual performance on screens. Both types benefit from surface hardening technologies, but display glass prioritizes smudge resistance and touch interaction, while optical glass emphasizes light transmission and minimal distortion.

Environmental Impact and Recyclability

Optical glass typically has a higher content of silica and fewer chemical additives, resulting in lower environmental impact during production and greater potential for recycling compared to display glass, which often contains heavy metals and complex coatings. Display glass, especially used in smartphones and TVs, poses more challenges for recycling due to layered compositions and embedded electronics that complicate material recovery. Advances in recycling technology for both types emphasize reducing landfill waste and recovering valuable components like rare earth elements to support sustainable manufacturing practices.

Choosing the Right Type of Glass for Your Application

Optical glass offers superior clarity, precise light transmission, and resistance to distortions, making it ideal for lenses, microscopes, and precision instruments. Display glass prioritizes durability, touch sensitivity, and anti-reflective coatings, essential for smartphones, tablets, and monitors. Selecting the right glass depends on whether clarity and optical performance or impact resistance and user interaction are primary requirements.

Optical glass vs Display glass Infographic

materialdif.com

materialdif.com