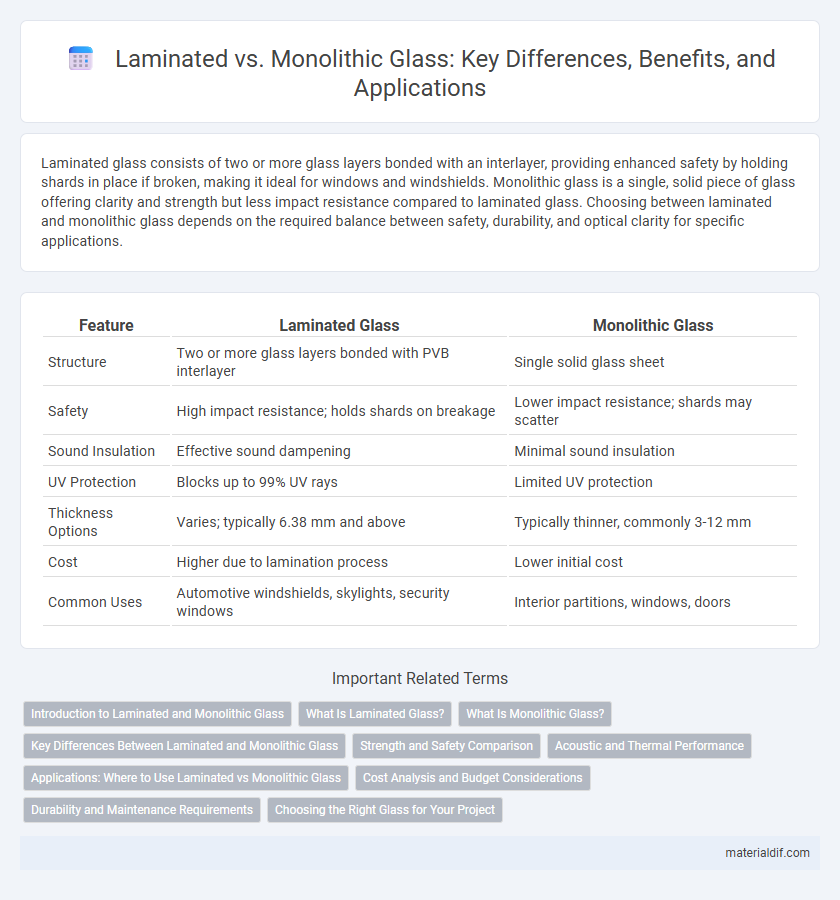

Laminated glass consists of two or more glass layers bonded with an interlayer, providing enhanced safety by holding shards in place if broken, making it ideal for windows and windshields. Monolithic glass is a single, solid piece of glass offering clarity and strength but less impact resistance compared to laminated glass. Choosing between laminated and monolithic glass depends on the required balance between safety, durability, and optical clarity for specific applications.

Table of Comparison

| Feature | Laminated Glass | Monolithic Glass |

|---|---|---|

| Structure | Two or more glass layers bonded with PVB interlayer | Single solid glass sheet |

| Safety | High impact resistance; holds shards on breakage | Lower impact resistance; shards may scatter |

| Sound Insulation | Effective sound dampening | Minimal sound insulation |

| UV Protection | Blocks up to 99% UV rays | Limited UV protection |

| Thickness Options | Varies; typically 6.38 mm and above | Typically thinner, commonly 3-12 mm |

| Cost | Higher due to lamination process | Lower initial cost |

| Common Uses | Automotive windshields, skylights, security windows | Interior partitions, windows, doors |

Introduction to Laminated and Monolithic Glass

Laminated glass consists of two or more glass layers bonded with an interlayer, providing enhanced safety and sound insulation compared to monolithic glass, which is a single, solid sheet of glass offering simplicity and clarity. The interlayer in laminated glass improves impact resistance by holding shards together upon breakage, making it ideal for automotive windshields and architectural applications requiring safety standards. Monolithic glass is commonly used in interior spaces and windows where minimal thickness and transparency are prioritized over security features.

What Is Laminated Glass?

Laminated glass consists of two or more layers of glass bonded together with an interlayer, typically made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), providing enhanced safety and sound insulation. This composite structure prevents shattering, as the interlayer holds the glass fragments together upon impact, making it ideal for automotive windshields and architectural applications. Unlike monolithic glass, which is a single pane and prone to breakage, laminated glass offers superior durability, security, and UV protection.

What Is Monolithic Glass?

Monolithic glass consists of a single, solid pane of glass without any interlayers, offering clear visibility and structural simplicity. It is commonly used in windows, doors, and facades where basic transparency and strength are required. Compared to laminated glass, monolithic glass lacks enhanced safety features such as impact resistance and noise reduction.

Key Differences Between Laminated and Monolithic Glass

Laminated glass consists of two or more glass layers bonded with an interlayer, providing enhanced safety and sound insulation, while monolithic glass is a single glass pane with limited impact resistance. Laminated glass offers superior shatter resistance and UV protection, making it ideal for automotive and architectural applications, whereas monolithic glass is typically used for basic window glazing due to its lower cost and ease of fabrication. The structural integrity and safety features of laminated glass distinguish it significantly from the simpler, less durable monolithic glass.

Strength and Safety Comparison

Laminated glass consists of two or more layers of glass bonded with an interlayer, offering superior strength and enhanced safety by holding shards together if broken, reducing injury risks. Monolithic glass is a single solid pane that provides basic strength but can shatter into sharp fragments upon impact, posing higher safety hazards. Laminated glass is preferred in applications requiring impact resistance and occupant protection, such as automotive windshields and architectural glazing.

Acoustic and Thermal Performance

Laminated glass offers superior acoustic insulation due to its interlayer that dampens sound vibrations, significantly reducing noise transmission compared to monolithic glass. Thermal performance in laminated glass is enhanced by the interlayer's ability to absorb and reflect heat, contributing to better energy efficiency. Monolithic glass lacks these benefits, making laminated glass the preferred choice for environments requiring improved soundproofing and thermal insulation.

Applications: Where to Use Laminated vs Monolithic Glass

Laminated glass is ideal for applications requiring enhanced safety and security, such as automotive windshields, skylights, and glass facades, due to its ability to hold together when shattered. Monolithic glass is suitable for interior use and non-critical areas like picture windows and doors where impact resistance is less crucial. Choosing laminated or monolithic glass depends on the need for strength, noise reduction, and UV protection specific to the installation environment.

Cost Analysis and Budget Considerations

Laminated glass generally incurs higher initial costs than monolithic glass due to its multiple layers and interlayer materials, impacting project budgets significantly. Monolithic glass offers a more economical option with lower production and installation expenses, ideal for cost-sensitive applications. Budget considerations should also factor in long-term benefits of laminated glass, such as enhanced safety, durability, and potential insurance savings, which can offset upfront costs over time.

Durability and Maintenance Requirements

Laminated glass offers superior durability compared to monolithic glass due to its multiple layers bonded with a strong interlayer, enhancing impact resistance and preventing shattering. Maintenance for laminated glass involves regular inspection of the interlayer for delamination or moisture infiltration, which can compromise its performance, whereas monolithic glass requires simpler cleaning routines but is more prone to cracks and breakage. The enhanced safety and longevity of laminated glass make it a preferred choice for applications demanding higher durability and minimal risk of hazardous fragmentation.

Choosing the Right Glass for Your Project

Laminated glass consists of two or more layers of glass bonded with an interlayer, offering enhanced safety, sound insulation, and UV protection, ideal for projects requiring impact resistance and security. Monolithic glass is a single layer of glass that provides straightforward transparency and cost-effectiveness, suitable for applications without heavy structural demands. Selecting the right glass depends on project needs such as safety, durability, acoustic performance, and budget constraints.

Laminated vs Monolithic Infographic

materialdif.com

materialdif.com