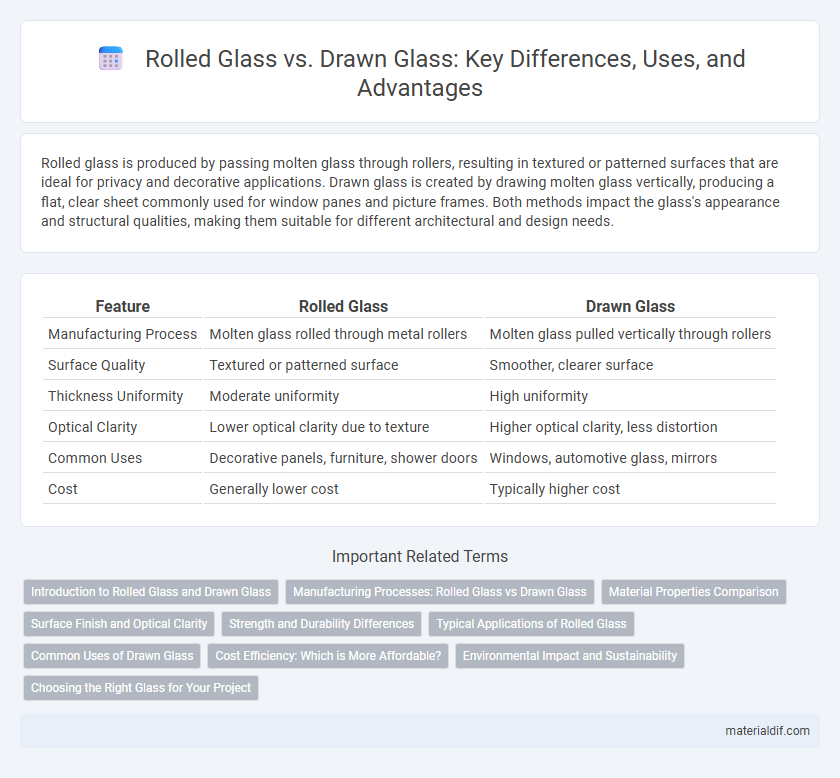

Rolled glass is produced by passing molten glass through rollers, resulting in textured or patterned surfaces that are ideal for privacy and decorative applications. Drawn glass is created by drawing molten glass vertically, producing a flat, clear sheet commonly used for window panes and picture frames. Both methods impact the glass's appearance and structural qualities, making them suitable for different architectural and design needs.

Table of Comparison

| Feature | Rolled Glass | Drawn Glass |

|---|---|---|

| Manufacturing Process | Molten glass rolled through metal rollers | Molten glass pulled vertically through rollers |

| Surface Quality | Textured or patterned surface | Smoother, clearer surface |

| Thickness Uniformity | Moderate uniformity | High uniformity |

| Optical Clarity | Lower optical clarity due to texture | Higher optical clarity, less distortion |

| Common Uses | Decorative panels, furniture, shower doors | Windows, automotive glass, mirrors |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Rolled Glass and Drawn Glass

Rolled glass is produced by pouring molten glass onto a flat surface and then rolling it to achieve uniform thickness, commonly used for decorative and architectural applications due to its textured or patterned finish. Drawn glass is created by vertically pulling molten glass upwards, forming continuous sheets with smoother surfaces ideal for clear, flat glass panels in windows and mirrors. Both manufacturing methods influence the glass's clarity, thickness consistency, and surface texture, determining their suitability for various industrial and design purposes.

Manufacturing Processes: Rolled Glass vs Drawn Glass

Rolled glass is produced by passing molten glass through rollers to achieve a uniform thickness and surface texture, allowing for patterned or textured finishes. Drawn glass is created by vertically drawing molten glass upwards, forming continuous sheets with smoother surfaces ideal for architectural and automotive applications. The rolled process offers more texture variety, while the drawn method provides higher clarity and optical quality.

Material Properties Comparison

Rolled glass exhibits higher surface texture and reduced optical clarity due to its manufacturing process, making it suitable for decorative and privacy applications, whereas drawn glass offers smoother surfaces and better uniformity with enhanced transparency ideal for windows and lenses. Rolled glass typically has increased thickness variability and lower tensile strength compared to drawn glass, which benefits from controlled cooling to improve durability and resistance to impact. Both types contain similar silica-based compositions but differ in mechanical properties and optical performance driven by their respective production techniques.

Surface Finish and Optical Clarity

Rolled glass features a textured surface achieved by passing molten glass between rollers, resulting in a patterned finish that diffuses light and reduces optical clarity, making it ideal for privacy applications. Drawn glass is produced by vertically drawing molten glass, creating a smoother surface with minimal distortions, offering superior optical clarity and consistent light transmission. Surface finish and optical clarity differences determine their suitability for uses ranging from decorative panels to precision glazing.

Strength and Durability Differences

Rolled glass features a textured surface with variable thickness, resulting in moderate strength and durability suitable for decorative applications. Drawn glass, produced through continuous pulling from molten glass, offers uniform thickness and enhanced structural integrity, making it more resistant to impact and suited for architectural uses. The consistent composition of drawn glass provides superior durability compared to the uneven nature of rolled glass.

Typical Applications of Rolled Glass

Rolled glass is commonly used in architectural applications such as windows, partitions, and decorative panels due to its textured surface that diffuses light while maintaining privacy. It is also widely employed in furniture manufacturing, including tabletops and cabinet doors, where durability and aesthetic appeal are essential. Typical applications extend to shower enclosures and automotive glazing, where safety and visibility balance is crucial.

Common Uses of Drawn Glass

Drawn glass is commonly used in architectural applications such as windows, doors, and partitions due to its smooth surface and consistent thickness. Its clarity and durability make it ideal for residential and commercial buildings, allowing for good light transmission while providing structural strength. This type of glass is also frequently used in automotive glazing and furniture surfaces, where both optical quality and toughness are essential.

Cost Efficiency: Which is More Affordable?

Rolled glass typically offers more cost efficiency due to faster production processes and lower material wastage compared to drawn glass. Drawn glass involves slower, more labor-intensive methods resulting in higher manufacturing costs. For large-scale projects prioritizing affordability, rolled glass generally proves to be the more budget-friendly option.

Environmental Impact and Sustainability

Rolled glass production consumes more energy due to higher furnace temperatures and mechanical rolling processes, resulting in increased carbon emissions compared to drawn glass. Drawn glass manufacturing utilizes continuous drawing techniques, reducing energy consumption and waste output, thereby contributing to a smaller environmental footprint. Both types can be recycled, but drawn glass's lower contamination rate makes it more sustainable for closed-loop recycling systems.

Choosing the Right Glass for Your Project

Rolled glass offers a textured surface created by passing molten glass through rollers, making it ideal for decorative and privacy applications where light diffusion is desired. Drawn glass features a smooth, uniform surface achieved by drawing molten glass upward, providing clarity and consistency, perfect for architectural windows and picture framing. Selecting the right glass depends on your project's need for texture versus transparency, durability, and aesthetic preferences, ensuring optimal functionality and visual appeal.

Rolled Glass vs Drawn Glass Infographic

materialdif.com

materialdif.com