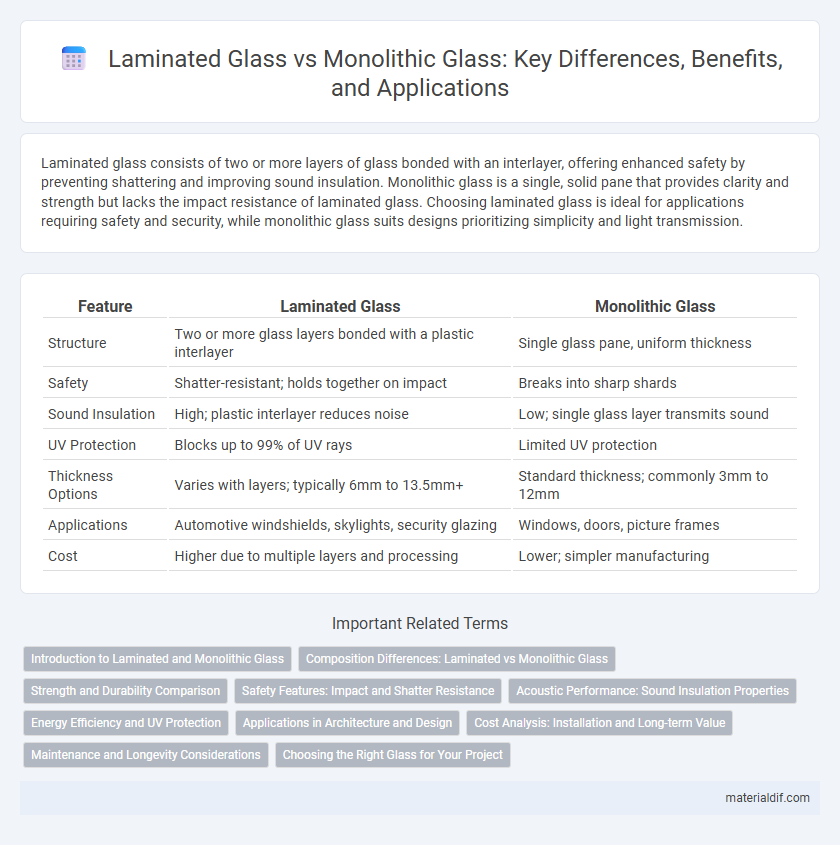

Laminated glass consists of two or more layers of glass bonded with an interlayer, offering enhanced safety by preventing shattering and improving sound insulation. Monolithic glass is a single, solid pane that provides clarity and strength but lacks the impact resistance of laminated glass. Choosing laminated glass is ideal for applications requiring safety and security, while monolithic glass suits designs prioritizing simplicity and light transmission.

Table of Comparison

| Feature | Laminated Glass | Monolithic Glass |

|---|---|---|

| Structure | Two or more glass layers bonded with a plastic interlayer | Single glass pane, uniform thickness |

| Safety | Shatter-resistant; holds together on impact | Breaks into sharp shards |

| Sound Insulation | High; plastic interlayer reduces noise | Low; single glass layer transmits sound |

| UV Protection | Blocks up to 99% of UV rays | Limited UV protection |

| Thickness Options | Varies with layers; typically 6mm to 13.5mm+ | Standard thickness; commonly 3mm to 12mm |

| Applications | Automotive windshields, skylights, security glazing | Windows, doors, picture frames |

| Cost | Higher due to multiple layers and processing | Lower; simpler manufacturing |

Introduction to Laminated and Monolithic Glass

Laminated glass consists of two or more glass layers bonded together with an interlayer, providing enhanced safety and sound insulation. Monolithic glass is a single, solid pane that offers clarity and strength but lacks the impact resistance of laminated glass. Both types serve distinct architectural and safety purposes in construction and automotive industries.

Composition Differences: Laminated vs Monolithic Glass

Laminated glass consists of two or more glass layers bonded together with an interlayer, typically made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), providing enhanced safety and sound insulation. Monolithic glass is a single, solid pane without any interlayer, making it less effective in impact resistance and noise reduction. The composition difference significantly influences performance characteristics, with laminated glass offering superior durability and protection compared to monolithic glass.

Strength and Durability Comparison

Laminated glass consists of two or more glass layers bonded with an interlayer, significantly enhancing its strength and impact resistance compared to monolithic glass, which is a single, continuous pane. The interlayer in laminated glass prevents shattering upon impact, maintaining structural integrity and providing superior durability, especially in safety-critical applications. Monolithic glass, while available in tempered versions for increased strength, generally lacks the multi-layer reinforcement that allows laminated glass to better withstand impacts and prolonged stress.

Safety Features: Impact and Shatter Resistance

Laminated glass offers superior safety features due to its multi-layer construction, which includes a plastic interlayer that holds shards together upon impact, minimizing the risk of injury. Monolithic glass, being a single pane, shatters into sharp pieces that can cause harm, lacking the impact resistance found in laminated options. This makes laminated glass a preferred choice for environments requiring enhanced protection against breakage and penetration.

Acoustic Performance: Sound Insulation Properties

Laminated glass provides superior acoustic performance compared to monolithic glass due to its interlayer, which dampens sound vibrations and reduces noise transmission. The polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) interlayer in laminated glass significantly improves sound insulation by absorbing sound waves and minimizing resonance. Monolithic glass, being a single solid pane, lacks this damping layer, making it less effective at blocking external noise and achieving high soundproofing standards.

Energy Efficiency and UV Protection

Laminated glass provides superior energy efficiency compared to monolithic glass by incorporating a polyvinyl butyral (PVB) interlayer that enhances insulation and reduces heat transfer. This interlayer also blocks up to 99% of harmful UV rays, protecting interiors from fading and damage. In contrast, monolithic glass offers minimal UV protection and lower thermal performance, making laminated glass the preferred choice for energy-saving and UV-blocking applications.

Applications in Architecture and Design

Laminated glass offers superior safety and sound insulation, making it ideal for use in architectural applications such as facades, skylights, and balustrades where impact resistance and security are crucial. Monolithic glass, being a single, uniform sheet, is commonly used in interior partitions and windows where cost efficiency and clarity are prioritized over enhanced performance features. Designers often select laminated glass for its ability to incorporate decorative interlayers and improve energy efficiency, while monolithic glass suits minimalist aesthetics requiring straightforward installation.

Cost Analysis: Installation and Long-term Value

Laminated glass generally has a higher initial installation cost compared to monolithic glass due to its multilayer construction involving interlayers such as PVB or SGP, which enhance safety and sound insulation. Despite the upfront expense, laminated glass offers superior long-term value by reducing replacement frequency and providing better impact resistance and UV protection, making it ideal for safety-conscious and energy-efficient applications. Monolithic glass, while cheaper initially, may incur higher maintenance costs over time due to its susceptibility to breakage and lower energy performance.

Maintenance and Longevity Considerations

Laminated glass offers superior durability and safety due to its interlayer, which holds shards in place upon breakage, reducing replacement frequency and maintenance costs compared to monolithic glass. Monolithic glass, while easier to clean and less expensive initially, is more prone to cracking and shattering, leading to higher long-term maintenance and replacement expenses. The enhanced longevity of laminated glass makes it a preferred choice for applications demanding extended lifespan and reduced upkeep.

Choosing the Right Glass for Your Project

Laminated glass offers enhanced safety and sound insulation by bonding two or more glass layers with an interlayer, making it ideal for projects requiring impact resistance and noise reduction. Monolithic glass, a single solid pane, provides clarity and cost-effectiveness but lacks the added strength and safety features of laminated glass. Selecting the right glass depends on project needs such as safety standards, acoustic performance, budget constraints, and desired visual properties.

Laminated glass vs Monolithic glass Infographic

materialdif.com

materialdif.com