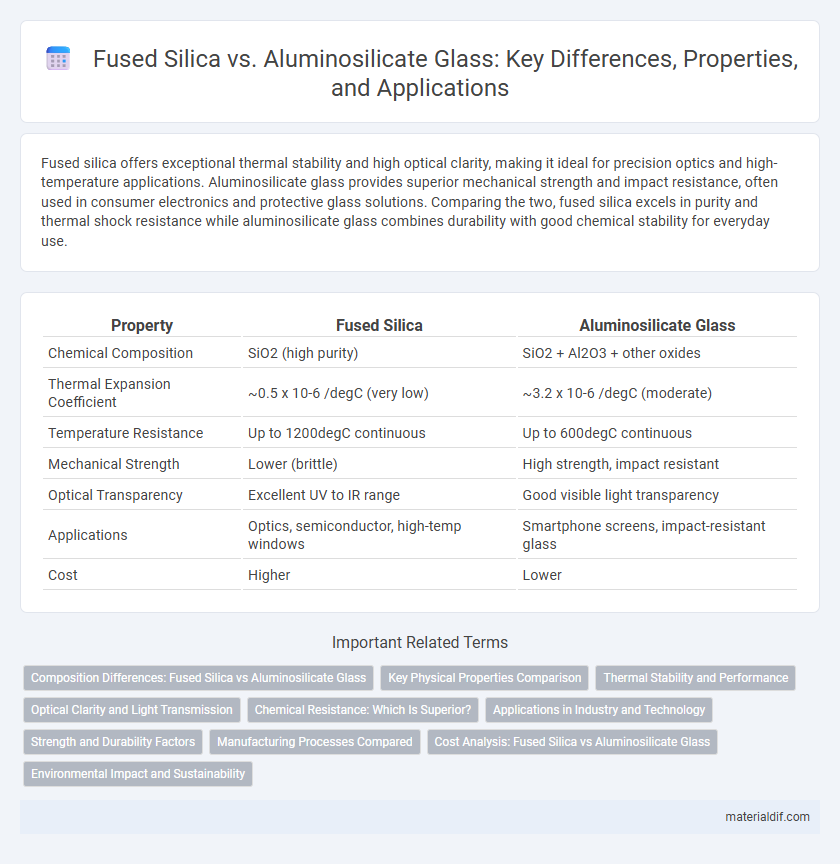

Fused silica offers exceptional thermal stability and high optical clarity, making it ideal for precision optics and high-temperature applications. Aluminosilicate glass provides superior mechanical strength and impact resistance, often used in consumer electronics and protective glass solutions. Comparing the two, fused silica excels in purity and thermal shock resistance while aluminosilicate glass combines durability with good chemical stability for everyday use.

Table of Comparison

| Property | Fused Silica | Aluminosilicate Glass |

|---|---|---|

| Chemical Composition | SiO2 (high purity) | SiO2 + Al2O3 + other oxides |

| Thermal Expansion Coefficient | ~0.5 x 10-6 /degC (very low) | ~3.2 x 10-6 /degC (moderate) |

| Temperature Resistance | Up to 1200degC continuous | Up to 600degC continuous |

| Mechanical Strength | Lower (brittle) | High strength, impact resistant |

| Optical Transparency | Excellent UV to IR range | Good visible light transparency |

| Applications | Optics, semiconductor, high-temp windows | Smartphone screens, impact-resistant glass |

| Cost | Higher | Lower |

Composition Differences: Fused Silica vs Aluminosilicate Glass

Fused silica primarily consists of pure silicon dioxide (SiO2) with minimal impurities, resulting in excellent thermal stability and optical clarity. Aluminosilicate glass contains a mixture of silicon dioxide, aluminum oxide (Al2O3), and other metal oxides, which enhance its mechanical strength and chemical resistance. The higher alumina content in aluminosilicate glass improves durability, while fused silica's nearly pure composition ensures superior thermal shock resistance and lower thermal expansion.

Key Physical Properties Comparison

Fused silica exhibits exceptional thermal stability with a melting point around 1710degC and a low coefficient of thermal expansion (~0.5 x 10-6 /degC), making it ideal for high-temperature applications. Aluminosilicate glass offers higher mechanical strength and enhanced scratch resistance, attributed to its alumina content, while maintaining good chemical durability. Both glasses possess excellent optical clarity, but fused silica's superior UV transmission and lower impurity levels provide advantages in precision optics and semiconductor manufacturing.

Thermal Stability and Performance

Fused silica exhibits superior thermal stability with a high melting point around 1,710degC and minimal thermal expansion, making it ideal for high-temperature applications. Aluminosilicate glass offers enhanced mechanical strength and thermal shock resistance due to its alumina content but has a lower melting point near 1,650degC. The choice between fused silica and aluminosilicate glass depends on the specific thermal performance requirements and operating temperature ranges of the application.

Optical Clarity and Light Transmission

Fused silica offers superior optical clarity with a high transmission rate of approximately 92% across UV to near-infrared wavelengths, making it ideal for precision optics and UV laser applications. Aluminosilicate glass, while more robust and impact-resistant, typically exhibits lower light transmission and slightly reduced clarity due to its higher iron content and structural impurities. The choice between fused silica and aluminosilicate glass depends on the balance between optical performance and mechanical durability for specific optical engineering needs.

Chemical Resistance: Which Is Superior?

Fused silica exhibits superior chemical resistance compared to aluminosilicate glass due to its high purity and silicon dioxide content, making it highly inert to most acids and alkalis. Aluminosilicate glass, while more resistant to mechanical stress, tends to be more susceptible to chemical attack, especially from hydrofluoric acid and strong alkalis. Laboratories and industries requiring extreme chemical inertness often prefer fused silica for applications involving aggressive chemical environments.

Applications in Industry and Technology

Fused silica offers exceptional thermal stability and high optical transparency, making it ideal for semiconductor manufacturing, fiber optic components, and high-precision lenses. Aluminosilicate glass provides enhanced mechanical strength and chemical durability, commonly used in smartphone screens, protective glass, and aerospace windows. Industries leverage fused silica for extreme temperature environments while aluminosilicate glass is favored for impact resistance and durability in consumer electronics.

Strength and Durability Factors

Fused silica offers exceptional thermal stability and superior chemical resistance, making it highly durable in extreme environments, while aluminosilicate glass excels in mechanical strength and impact resistance due to its reinforced alumina content. The inherent low thermal expansion coefficient of fused silica enhances its resistance to thermal shock, whereas aluminosilicate glass provides enhanced scratch resistance and toughness, ideal for protective applications like smartphone screens. Both materials deliver high durability, but fused silica is preferred for precision optics, and aluminosilicate glass is favored in rugged consumer electronics.

Manufacturing Processes Compared

Fused silica is produced through the melting of high-purity silica sand in an electric or plasma furnace, resulting in a glass with exceptional thermal and chemical resistance due to its amorphous silicon dioxide structure. Aluminosilicate glass manufacturing involves melting alumina and silica with other metal oxides at high temperatures, often followed by ion-exchange strengthening processes that enhance its mechanical durability and impact resistance. The distinct manufacturing differences directly influence their respective applications, with fused silica favored for optical purity and thermal stability, while aluminosilicate is preferred for resilient, scratch-resistant consumer glass products.

Cost Analysis: Fused Silica vs Aluminosilicate Glass

Fused silica typically incurs higher production costs due to its superior purity and thermal stability, making it ideal for high-precision optical and semiconductor applications. Aluminosilicate glass offers a more cost-effective solution with enhanced mechanical strength and chemical resistance, suitable for consumer electronics and protective covers. Cost analysis reveals that although fused silica demands greater upfront investment, its longevity and performance benefits may justify expenses in specialized industries, whereas aluminosilicate glass balances affordability with durability for mass-market use.

Environmental Impact and Sustainability

Fused silica exhibits superior environmental sustainability due to its high purity and energy-efficient manufacturing process, which generates fewer greenhouse gas emissions compared to aluminosilicate glass. Aluminosilicate glass, while durable and used extensively in consumer electronics, often involves more energy-intensive production and complex recycling methods that increase its environmental footprint. Selecting fused silica over aluminosilicate glass reduces resource consumption and facilitates easier recycling, advancing sustainable material management in various industries.

Fused silica vs Aluminosilicate glass Infographic

materialdif.com

materialdif.com