Recycled glass significantly reduces energy consumption and raw material extraction compared to virgin glass, making it a more sustainable choice for manufacturing. While virgin glass offers consistent quality due to its pure raw materials, recycled glass effectively lowers carbon emissions and waste in landfills. Incorporating recycled glass in production supports circular economy principles without compromising the durability and clarity of the final product.

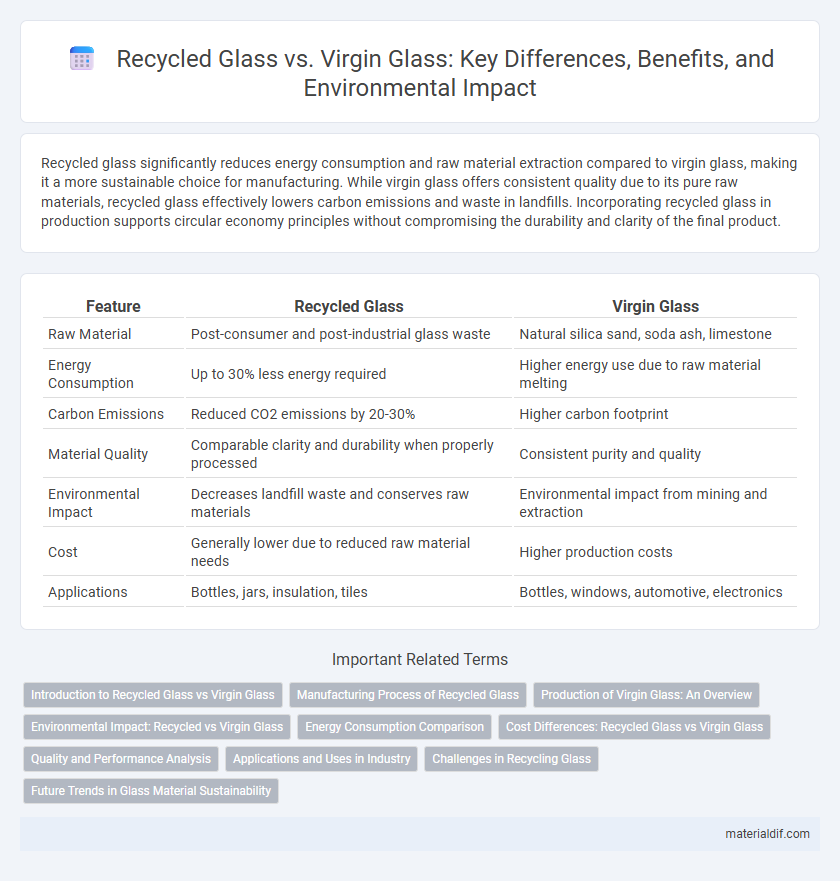

Table of Comparison

| Feature | Recycled Glass | Virgin Glass |

|---|---|---|

| Raw Material | Post-consumer and post-industrial glass waste | Natural silica sand, soda ash, limestone |

| Energy Consumption | Up to 30% less energy required | Higher energy use due to raw material melting |

| Carbon Emissions | Reduced CO2 emissions by 20-30% | Higher carbon footprint |

| Material Quality | Comparable clarity and durability when properly processed | Consistent purity and quality |

| Environmental Impact | Decreases landfill waste and conserves raw materials | Environmental impact from mining and extraction |

| Cost | Generally lower due to reduced raw material needs | Higher production costs |

| Applications | Bottles, jars, insulation, tiles | Bottles, windows, automotive, electronics |

Introduction to Recycled Glass vs Virgin Glass

Recycled glass is produced by melting down used glass products, reducing the need for raw materials and lowering energy consumption by up to 30% compared to virgin glass production. Virgin glass is manufactured from raw materials like sand, soda ash, and limestone, requiring higher energy inputs and resulting in greater carbon emissions. Using recycled glass significantly decreases landfill waste and conserves natural resources while maintaining the same quality and durability as virgin glass.

Manufacturing Process of Recycled Glass

Recycled glass manufacturing reduces energy consumption by up to 40% compared to virgin glass production, as it requires melting cullet at lower temperatures. The process involves sorting, cleaning, and crushing post-consumer glass before remelting, which minimizes raw material extraction and greenhouse gas emissions. Using recycled glass also shortens the manufacturing cycle, increasing efficiency and lowering overall production costs.

Production of Virgin Glass: An Overview

Production of virgin glass involves melting raw materials such as silica sand, soda ash, and limestone at temperatures exceeding 1700degC to form a homogeneous molten glass. This high-energy process results in a pure, clear product often used in high-quality applications where optical clarity and chemical resistance are critical. Virgin glass production demands significant natural resources and energy, contributing to higher carbon emissions compared to recycled glass manufacturing.

Environmental Impact: Recycled vs Virgin Glass

Recycled glass significantly reduces environmental impact by lowering energy consumption and greenhouse gas emissions compared to virgin glass production. Using recycled glass decreases the need for raw materials like sand and limestone, conserving natural resources and minimizing habitat disruption. This process also cuts landfill waste, promoting a circular economy and reducing overall pollution associated with glass manufacturing.

Energy Consumption Comparison

Recycled glass significantly reduces energy consumption compared to virgin glass, using up to 40% less energy during the melting process due to its lower melting point. Virgin glass production requires melting raw materials such as sand, soda ash, and limestone at higher temperatures, which consumes more fuel and increases carbon emissions. Utilizing recycled cullet not only conserves natural resources but also lowers greenhouse gas emissions associated with glass manufacturing.

Cost Differences: Recycled Glass vs Virgin Glass

Recycled glass typically costs 20-30% less to produce than virgin glass due to lower raw material and energy expenses. The use of cullet reduces furnace temperatures by up to 200degC, resulting in significant energy savings during manufacturing. Despite initial collection and sorting costs, the overall production cost of recycled glass remains more economical compared to virgin glass.

Quality and Performance Analysis

Recycled glass often matches or exceeds the quality of virgin glass, maintaining clarity, strength, and durability through advanced processing techniques. Performance analysis shows that recycled glass performs comparably in thermal resistance and structural integrity, making it suitable for high-standard applications such as packaging and construction. The consistent quality of recycled glass also contributes to energy savings and reduced environmental impact without compromising product performance.

Applications and Uses in Industry

Recycled glass is extensively used in the production of container glass, fiberglass insulation, and abrasives, benefiting industries by reducing energy consumption and costs compared to virgin glass. Virgin glass, known for its superior purity and strength, is preferred in high-performance applications such as optical lenses, specialty glassware, and advanced electronics. Industrial sectors prioritize recycled glass for sustainable packaging and construction materials, while virgin glass remains essential for precision engineering and critical infrastructure.

Challenges in Recycling Glass

Recycling glass presents significant challenges such as contamination from mixed materials and the high energy required for remelting process, which can reduce efficiency compared to producing virgin glass. Fragmentation during collection and sorting often leads to smaller glass cullet sizes, negatively impacting the quality of recycled glass and limiting its reuse in manufacturing. Moreover, the presence of cobalt, selenium, or lead impurities complicates recycling streams, making it difficult to maintain consistent batch quality in recycled glass production.

Future Trends in Glass Material Sustainability

Recycled glass significantly reduces energy consumption and raw material extraction compared to virgin glass, promoting a circular economy in the glass industry. Future trends emphasize increased recycling rates and advancements in closed-loop manufacturing processes to minimize environmental impact and carbon footprint. Innovations in glass composition and digital sorting technologies are expected to enhance the quality and efficiency of recycled glass, driving sustainable material solutions.

Recycled glass vs Virgin glass Infographic

materialdif.com

materialdif.com