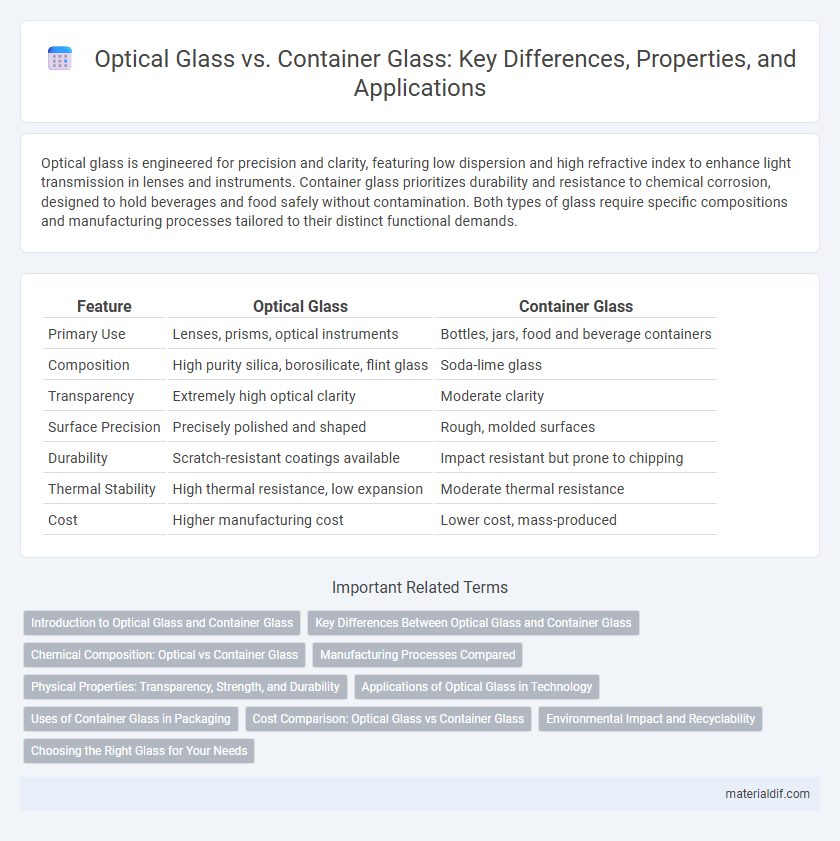

Optical glass is engineered for precision and clarity, featuring low dispersion and high refractive index to enhance light transmission in lenses and instruments. Container glass prioritizes durability and resistance to chemical corrosion, designed to hold beverages and food safely without contamination. Both types of glass require specific compositions and manufacturing processes tailored to their distinct functional demands.

Table of Comparison

| Feature | Optical Glass | Container Glass |

|---|---|---|

| Primary Use | Lenses, prisms, optical instruments | Bottles, jars, food and beverage containers |

| Composition | High purity silica, borosilicate, flint glass | Soda-lime glass |

| Transparency | Extremely high optical clarity | Moderate clarity |

| Surface Precision | Precisely polished and shaped | Rough, molded surfaces |

| Durability | Scratch-resistant coatings available | Impact resistant but prone to chipping |

| Thermal Stability | High thermal resistance, low expansion | Moderate thermal resistance |

| Cost | Higher manufacturing cost | Lower cost, mass-produced |

Introduction to Optical Glass and Container Glass

Optical glass is a highly specialized type of glass designed for precision applications such as lenses, prisms, and optical instruments, characterized by its controlled refractive index and low dispersion. Container glass, commonly used for packaging food and beverages, emphasizes durability, chemical resistance, and transparency, typically composed of soda-lime silica glass. The distinct compositions and manufacturing processes result in unique properties tailored for optical clarity versus structural strength and safety.

Key Differences Between Optical Glass and Container Glass

Optical glass is specially formulated for high clarity, precise light transmission, and minimal distortion, with applications in lenses, prisms, and other optical devices. Container glass, primarily soda-lime glass, is designed for durability, chemical resistance, and cost-effectiveness to hold beverages and food products securely. The key differences lie in their chemical compositions, optical properties, and intended industrial uses, influencing manufacturing processes and quality standards.

Chemical Composition: Optical vs Container Glass

Optical glass is engineered with precise chemical compositions, including high levels of silica (SiO2), boron oxide (B2O3), and specific metal oxides like titanium dioxide (TiO2) and lanthanum oxide (La2O3), to achieve superior clarity, refractive index, and minimal dispersion. Container glass primarily consists of soda-lime silica, comprising approximately 70-74% SiO2, 12-16% Na2O (sodium oxide), and 5-12% CaO (calcium oxide), optimized for durability, chemical resistance, and cost-effective mass production. The variations in metal oxide content and purity directly influence optical glass's light-transmission properties versus the robustness and chemical inertness required in container glass.

Manufacturing Processes Compared

Optical glass manufacturing involves precise melting and refining processes to ensure high purity and controlled refractive index, often using batch melting and annealing techniques to minimize stress and impurities for clear optical performance. Container glass production uses continuous melting in furnaces, followed by forming processes such as blowing or pressing to create durable, uniform bottles and jars with chemical resistance and structural strength. The key difference lies in optical glass requiring stringent quality control for optical clarity, while container glass prioritizes mass production efficiency and mechanical durability.

Physical Properties: Transparency, Strength, and Durability

Optical glass exhibits superior transparency with low light distortion, essential for precision lenses, while container glass prioritizes chemical durability to safely store food and beverages. Optical glass is engineered for high strength and resistance to thermal expansion, ensuring clarity under varying environmental conditions. Container glass, although less transparent, offers robust resistance to impact and thermal shocks for practical durability in everyday use.

Applications of Optical Glass in Technology

Optical glass is crucial in the manufacturing of lenses, prisms, and laser components due to its precise refractive index and low dispersion properties, enabling high-performance imaging and photonics. This glass type is extensively used in microscopes, telescopes, cameras, and fiber optics for telecommunications, enhancing light transmission and signal clarity. Unlike container glass, which is designed for durability and chemical resistance in packaging, optical glass demands superior purity and homogeneity to support advanced technological applications.

Uses of Container Glass in Packaging

Container glass is primarily used in packaging applications such as bottles, jars, and other storage vessels for food, beverages, and pharmaceuticals. Its chemical durability and impermeability protect contents from contamination, preserving freshness and flavor. Unlike optical glass, container glass is manufactured to withstand mechanical stresses and temperature variations encountered during shipping and handling.

Cost Comparison: Optical Glass vs Container Glass

Optical glass typically incurs higher production costs than container glass due to its precise material composition and stricter manufacturing tolerances required for clarity and refractive properties. Container glass benefits from large-scale production and less stringent quality control, resulting in significantly lower per-unit expenses. The cost disparity reflects the specialized applications of optical glass in lenses and instruments versus the mass-market use of container glass in packaging.

Environmental Impact and Recyclability

Optical glass, containing high purity silica and specialized additives, requires energy-intensive manufacturing processes that limit its recyclability compared to container glass, which is primarily soda-lime glass widely recycled in global waste streams. Container glass exhibits a circular economy advantage due to efficient recycling infrastructure that reduces raw material extraction and energy consumption, significantly lowering its environmental impact. In contrast, optical glass's complex composition and lower volume restrict its recycling potential, prompting the need for specialized disposal or reuse methods to mitigate waste.

Choosing the Right Glass for Your Needs

Optical glass is engineered for high precision in lenses and scientific instruments, offering exceptional clarity and low distortion due to its controlled refractive index and minimal impurities. Container glass prioritizes durability and chemical resistance, making it ideal for packaging food, beverages, and pharmaceuticals with an emphasis on safety and preservation. Selecting the right glass depends on application requirements: optical glass is suited for performance-critical uses, while container glass is designed for practical, everyday containment solutions.

Optical glass vs Container glass Infographic

materialdif.com

materialdif.com