Lead glass contains lead oxide, which enhances its refractive index and weight, resulting in improved clarity and brilliance, commonly used in fine glassware and optics. Lead-free glass eliminates lead for environmental and health safety, relying on alternative materials to maintain durability and transparency suitable for everyday use. Both types offer distinct advantages, with lead glass favored for decorative appeal and lead-free glass preferred for sustainability.

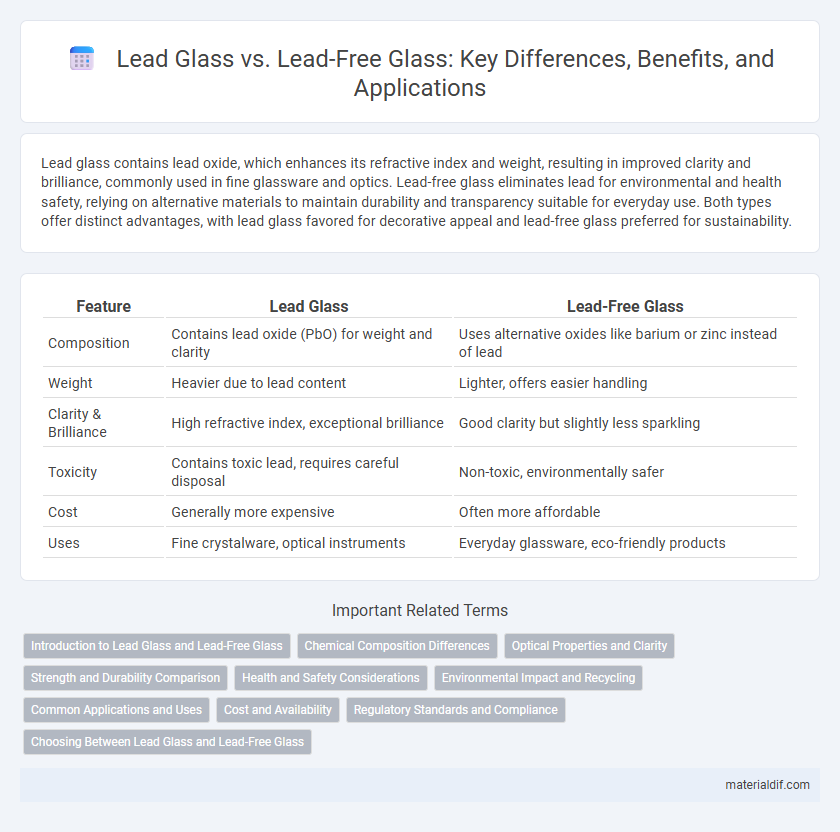

Table of Comparison

| Feature | Lead Glass | Lead-Free Glass |

|---|---|---|

| Composition | Contains lead oxide (PbO) for weight and clarity | Uses alternative oxides like barium or zinc instead of lead |

| Weight | Heavier due to lead content | Lighter, offers easier handling |

| Clarity & Brilliance | High refractive index, exceptional brilliance | Good clarity but slightly less sparkling |

| Toxicity | Contains toxic lead, requires careful disposal | Non-toxic, environmentally safer |

| Cost | Generally more expensive | Often more affordable |

| Uses | Fine crystalware, optical instruments | Everyday glassware, eco-friendly products |

Introduction to Lead Glass and Lead-Free Glass

Lead glass, commonly known as crystal, contains a significant percentage of lead oxide, typically between 18% and 30%, which enhances its brilliance, refractive index, and weight. Lead-free glass substitutes lead oxide with alternative oxides such as barium, zinc, or potassium, offering improved environmental and health safety while maintaining clarity and durability. Both types of glass are widely utilized in decorative arts, optics, and high-quality glassware, each balancing performance characteristics with regulatory and ecological considerations.

Chemical Composition Differences

Lead glass contains significant amounts of lead oxide, typically 24-30%, which enhances its refractive index and brilliance, making it ideal for decorative and optical applications. Lead-free glass replaces lead oxide with alternative oxides such as barium, zinc, or potassium, reducing toxicity while maintaining desirable properties like clarity and durability. The chemical composition difference critically affects the glass's weight, chemical resistance, and environmental impact, with lead glass being denser and more prone to environmental hazards compared to lead-free variants.

Optical Properties and Clarity

Lead glass contains lead oxide, which increases its refractive index and density, resulting in enhanced brilliance and clarity with superior light dispersion. Lead-free glass, often made with alternatives like barium or zinc oxides, offers improved optical clarity by reducing yellowish tints and is more environmentally friendly. While lead glass excels in sparkle and weight, lead-free glass provides comparable transparency and is preferred for applications requiring non-toxic materials.

Strength and Durability Comparison

Lead glass offers enhanced strength and durability due to the high density of lead oxide, which increases its resistance to impact and thermal stress. Lead-free glass, often composed of alternative metal oxides like barium or zinc, provides comparable durability but generally exhibits slightly lower mechanical strength and scratch resistance. In applications demanding superior toughness and longevity, lead glass remains preferred despite environmental concerns associated with lead content.

Health and Safety Considerations

Lead glass contains lead oxide, which enhances clarity and brilliance but poses health risks due to lead exposure during manufacturing or breakage. Lead-free glass eliminates these hazards by using alternative materials, making it safer for both consumers and workers without compromising quality. Choosing lead-free glass reduces the risk of lead poisoning and environmental contamination, aligning with stricter health and safety regulations.

Environmental Impact and Recycling

Lead glass contains significant amounts of lead oxide, which poses environmental challenges due to lead's toxicity and difficulties in recycling processes, potentially contaminating waste streams and requiring specialized handling. Lead-free glass eliminates these risks by using alternative formulations that reduce hazardous waste and improve recyclability, facilitating safer disposal and more efficient recovery. Recycling lead-free glass is more environmentally sustainable, as it minimizes pollution and supports circular economy initiatives without compromising glass quality.

Common Applications and Uses

Lead glass is commonly used in radiation shielding, optical lenses, and decorative art due to its high refractive index and density, which enhance clarity and protection. Lead-free glass finds frequent applications in food and beverage containers, pharmaceutical packaging, and environmentally sensitive settings because it eliminates lead contamination risks. Both types serve specialized roles: lead glass excels in precision optics and industrial safety, while lead-free glass prioritizes health and ecological safety in everyday products.

Cost and Availability

Lead glass typically costs more than lead-free glass due to the inclusion of lead oxide, which enhances clarity and density but raises production expenses. Lead-free glass offers greater availability and affordability as it uses alternative materials like soda-lime or borosilicate, making it suitable for mass-market applications. Cost-effective manufacturing and widespread supply chains make lead-free glass the preferred choice for everyday use and eco-friendly designs.

Regulatory Standards and Compliance

Lead glass, containing up to 30% lead oxide, is subject to stringent regulatory standards such as the RoHS Directive and REACH regulations in the EU, which limit lead content due to its toxicity and environmental impact. Lead-free glass complies more easily with global safety and environmental regulations, making it preferable for consumer products and packaging in markets prioritizing health and sustainability. Compliance with standards like FDA food contact guidelines and NSF certification for lead-free glass ensures safer use in medical, food, and beverage applications.

Choosing Between Lead Glass and Lead-Free Glass

Choosing between lead glass and lead-free glass depends on factors such as lead content, environmental impact, and intended use. Lead glass, containing up to 24% lead oxide, offers superior clarity and brilliance, making it ideal for fine crystalware and decorative items. Lead-free glass eliminates lead-related health risks and suits food and beverage containers, emphasizing safety and eco-friendliness without compromising durability.

Lead Glass vs Lead-Free Glass Infographic

materialdif.com

materialdif.com