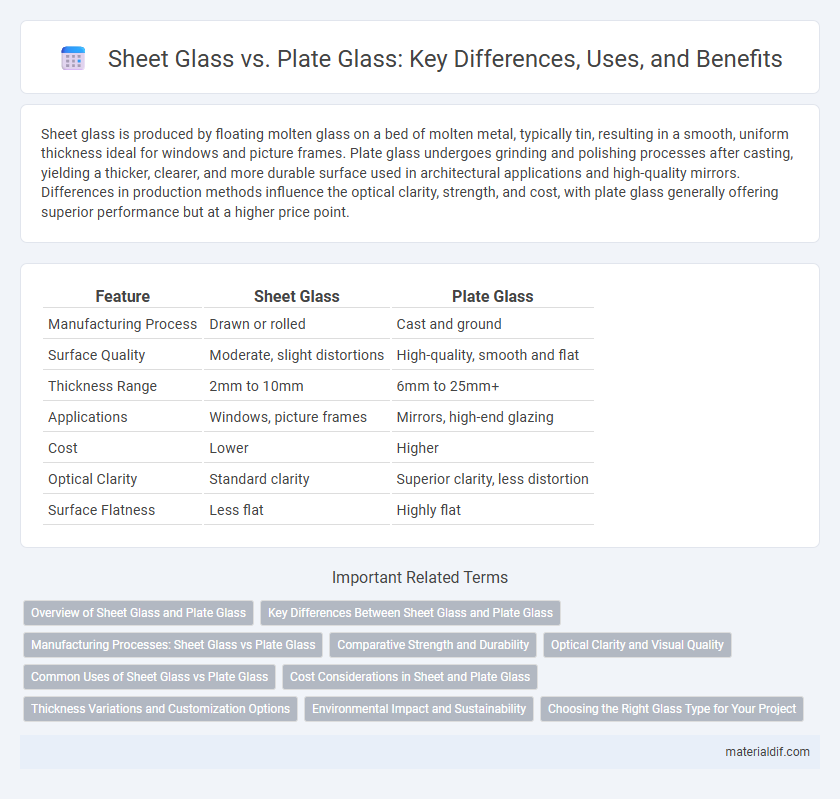

Sheet glass is produced by floating molten glass on a bed of molten metal, typically tin, resulting in a smooth, uniform thickness ideal for windows and picture frames. Plate glass undergoes grinding and polishing processes after casting, yielding a thicker, clearer, and more durable surface used in architectural applications and high-quality mirrors. Differences in production methods influence the optical clarity, strength, and cost, with plate glass generally offering superior performance but at a higher price point.

Table of Comparison

| Feature | Sheet Glass | Plate Glass |

|---|---|---|

| Manufacturing Process | Drawn or rolled | Cast and ground |

| Surface Quality | Moderate, slight distortions | High-quality, smooth and flat |

| Thickness Range | 2mm to 10mm | 6mm to 25mm+ |

| Applications | Windows, picture frames | Mirrors, high-end glazing |

| Cost | Lower | Higher |

| Optical Clarity | Standard clarity | Superior clarity, less distortion |

| Surface Flatness | Less flat | Highly flat |

Overview of Sheet Glass and Plate Glass

Sheet glass is produced by drawing molten glass vertically or horizontally into thin, uniform sheets, commonly used in windows and mirrors due to its smooth surface and consistent thickness. Plate glass, created by melting and rolling molten glass into thick, flat slabs followed by grinding and polishing, offers superior clarity and strength, suitable for high-quality architectural applications and automotive windshields. Both types differ in production techniques, surface finish, and optical quality, impacting their specific use cases in construction and design.

Key Differences Between Sheet Glass and Plate Glass

Sheet glass, produced by drawing molten glass through rollers, typically has slight distortions and is less uniform in thickness compared to plate glass. Plate glass undergoes a casting and grinding process that results in high optical clarity, flatness, and smoothness, making it ideal for automotive and architectural applications requiring better visual quality. The key differences lie in their manufacturing processes, surface finish, and suitability for precision uses where plate glass outperforms sheet glass in strength and appearance.

Manufacturing Processes: Sheet Glass vs Plate Glass

Sheet glass is produced by floating molten glass on a bed of molten tin, creating a continuous, uniform thickness ideal for windowpanes and architectural applications. Plate glass manufacturing involves casting molten glass onto a flat surface and then grinding and polishing to achieve a smooth, high-quality finish suitable for mirrors and automotive glass. The floating process of sheet glass allows for faster production, whereas plate glass requires more labor-intensive finishing steps for clarity and strength.

Comparative Strength and Durability

Sheet glass generally exhibits lower strength and durability compared to plate glass due to its manufacturing process, which results in thinner and less uniform thickness. Plate glass undergoes a more controlled casting and grinding process, enhancing its structural integrity and resistance to impact and weathering. This makes plate glass more suitable for applications requiring higher durability and load-bearing capacity.

Optical Clarity and Visual Quality

Sheet glass, produced by floating molten glass on a bed of molten metal, offers consistent optical clarity with minimal distortion suitable for standard windows and framing. Plate glass undergoes grinding and polishing, resulting in superior visual quality with high optical purity and nearly flawless transparency essential for precision mirrors and high-end displays. The advanced finishing of plate glass ensures reduced optical aberrations, making it preferable for applications demanding exceptional clarity and visual fidelity.

Common Uses of Sheet Glass vs Plate Glass

Sheet glass is commonly used in residential windows, picture frames, and glass doors due to its lightweight and easy-to-cut properties. Plate glass, known for its superior clarity and smooth surface, is often used in high-end storefronts, mirrors, and architectural facades. The choice between sheet and plate glass depends on the specific application requirements for transparency, strength, and finish quality.

Cost Considerations in Sheet and Plate Glass

Sheet glass is generally more cost-effective due to its mass production and simpler manufacturing process, making it ideal for large-scale projects. Plate glass, while more expensive, offers superior optical clarity and thickness uniformity, which justifies its higher cost in high-end architectural and automotive applications. Budget constraints often dictate the choice between the affordability of sheet glass and the premium quality of plate glass.

Thickness Variations and Customization Options

Sheet glass typically ranges from 2mm to 6mm in thickness, offering flexibility for standard window applications, while plate glass is produced in thicker slabs, often from 6mm up to 25mm, ideal for structural or high-strength uses. Customization options for sheet glass include tinting and basic treatments, whereas plate glass allows for extensive customization such as polishing, grinding, and tempering to meet specific architectural or industrial requirements. The choice between sheet and plate glass often hinges on the desired thickness and the level of surface finish or modification needed for the project.

Environmental Impact and Sustainability

Sheet glass production typically consumes less energy and generates fewer emissions compared to plate glass, making it a more environmentally sustainable option. Plate glass manufacturing involves additional processes such as grinding and polishing, which increase resource use and carbon footprint. Selecting sheet glass contributes to reduced environmental impact through lower energy consumption and minimized waste generation.

Choosing the Right Glass Type for Your Project

Sheet glass offers a thinner, lighter option ideal for residential windows and simple framing, while plate glass provides superior clarity, thickness, and strength suitable for commercial storefronts and structural applications. Assessing factors such as load-bearing requirements, optical quality, and budget helps determine whether sheet or plate glass best meets the demands of your construction or renovation project. Prioritizing plate glass enhances durability and visual appeal in high-traffic or architectural settings, whereas sheet glass remains cost-effective for standard glazing needs.

Sheet glass vs Plate glass Infographic

materialdif.com

materialdif.com