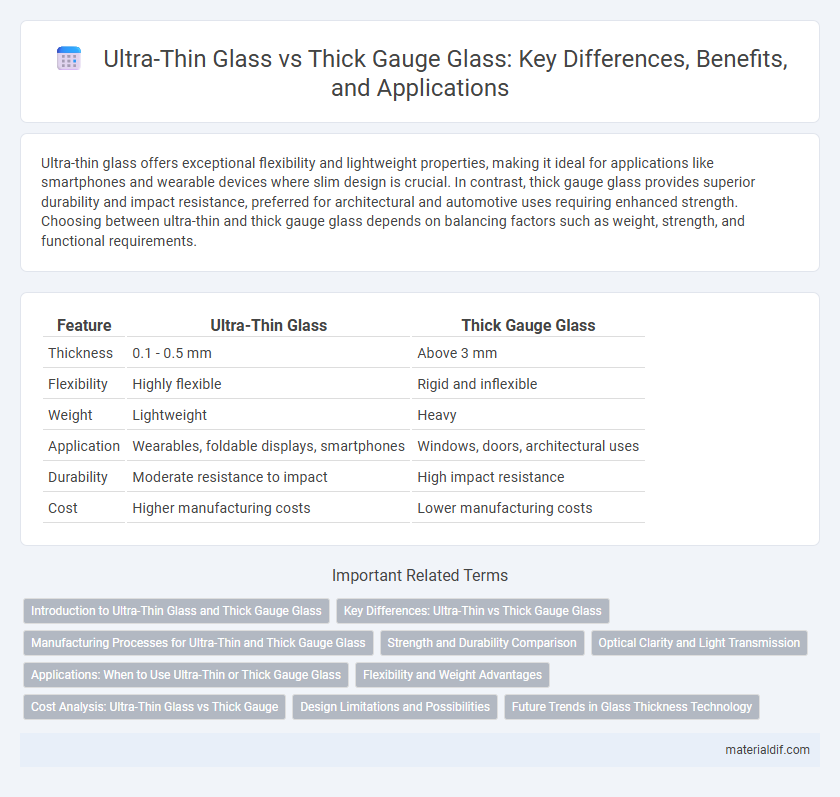

Ultra-thin glass offers exceptional flexibility and lightweight properties, making it ideal for applications like smartphones and wearable devices where slim design is crucial. In contrast, thick gauge glass provides superior durability and impact resistance, preferred for architectural and automotive uses requiring enhanced strength. Choosing between ultra-thin and thick gauge glass depends on balancing factors such as weight, strength, and functional requirements.

Table of Comparison

| Feature | Ultra-Thin Glass | Thick Gauge Glass |

|---|---|---|

| Thickness | 0.1 - 0.5 mm | Above 3 mm |

| Flexibility | Highly flexible | Rigid and inflexible |

| Weight | Lightweight | Heavy |

| Application | Wearables, foldable displays, smartphones | Windows, doors, architectural uses |

| Durability | Moderate resistance to impact | High impact resistance |

| Cost | Higher manufacturing costs | Lower manufacturing costs |

Introduction to Ultra-Thin Glass and Thick Gauge Glass

Ultra-thin glass typically measures less than 0.5 mm in thickness, offering exceptional flexibility and lightweight properties ideal for advanced electronics and flexible displays. Thick gauge glass, often exceeding 6 mm thickness, provides superior durability, enhanced impact resistance, and increased structural support in architectural and automotive applications. The choice between ultra-thin and thick gauge glass depends on specific performance requirements such as flexibility, weight constraints, and strength.

Key Differences: Ultra-Thin vs Thick Gauge Glass

Ultra-thin glass typically measures less than 0.5 mm in thickness, offering exceptional flexibility, lightweight properties, and high transparency, making it suitable for advanced displays and mobile devices. Thick gauge glass, often exceeding 3 mm, provides superior strength, durability, and impact resistance, favored in architectural and automotive applications. The contrast in thickness directly influences thermal insulation, weight, and mechanical performance, defining their distinct use cases across industries.

Manufacturing Processes for Ultra-Thin and Thick Gauge Glass

Ultra-thin glass manufacturing involves precision float processes and advanced tempering techniques that achieve thicknesses below 0.5 millimeters while maintaining flexibility and strength. Thick gauge glass production utilizes traditional float glass methods followed by controlled annealing and cutting to reach thicknesses above 6 millimeters, optimizing durability and structural integrity. Both processes incorporate chemical strengthening and surface treatments tailored to the glass's intended application, impacting performance characteristics.

Strength and Durability Comparison

Ultra-thin glass exhibits increased flexibility and resistance to cracking compared to thick gauge glass, making it ideal for applications requiring lightweight yet durable materials. Thick gauge glass, while heavier, provides superior impact resistance and structural support, enhancing overall strength in load-bearing scenarios. Understanding the balance between ultra-thin glass's flexibility and thick gauge's robustness is essential for selecting the appropriate glass type in architectural and technological designs.

Optical Clarity and Light Transmission

Ultra-thin glass offers superior optical clarity compared to thick gauge glass due to its reduced thickness, minimizing light distortion and enhancing transparency. Light transmission rates in ultra-thin glass typically exceed 90%, allowing more natural light to pass through, which is ideal for applications requiring high visual fidelity. Thick gauge glass often results in increased light refraction and slight color tinting, reducing overall clarity and light transmission efficiency.

Applications: When to Use Ultra-Thin or Thick Gauge Glass

Ultra-thin glass offers exceptional flexibility and lightweight properties, making it ideal for advanced applications such as foldable smartphones, wearable devices, and high-precision optical components. Thick gauge glass provides superior durability and impact resistance, suited for architectural facades, automotive windshields, and heavy-duty industrial equipment. Choosing between ultra-thin and thick gauge glass depends on the required balance between strength, weight, and flexibility in the specific application.

Flexibility and Weight Advantages

Ultra-thin glass offers superior flexibility compared to thick gauge glass, making it ideal for applications requiring bending or shaping without compromising structural integrity. Its significantly lower weight enhances portability and reduces overall product mass in industries such as electronics and automotive manufacturing. These advantages contribute to improved design versatility and energy efficiency in devices and architectural solutions.

Cost Analysis: Ultra-Thin Glass vs Thick Gauge

Ultra-thin glass typically incurs higher production costs due to advanced manufacturing technologies and stricter quality controls, whereas thick gauge glass benefits from established, large-scale fabrication methods that reduce per-unit expenses. The material efficiency of ultra-thin glass offers cost-saving potential in transportation and installation, offsetting initial price differences in long-term projects. Bulk procurement and simplified handling of thick gauge glass contribute to lower upfront investment, but the lightweight nature of ultra-thin glass makes it advantageous in applications demanding flexibility and weight reduction.

Design Limitations and Possibilities

Ultra-thin glass offers exceptional flexibility and lightweight properties, enabling innovative curved and foldable display designs that thick gauge glass cannot achieve. Thick gauge glass provides superior durability and impact resistance, ideal for applications requiring robust protection but limiting intricate form factors. Designers must balance ultra-thin glass's delicate nature with its transformative aesthetic possibilities against the rigidity and toughness of thick gauge options.

Future Trends in Glass Thickness Technology

Future trends in glass thickness technology highlight the increasing adoption of ultra-thin glass due to its superior flexibility, lightweight properties, and enhanced optical clarity compared to traditional thick gauge glass. Innovations in manufacturing processes, such as advanced chemical strengthening and precision cutting, enable ultra-thin glass to maintain durability while supporting applications in flexible displays, wearable devices, and solar panels. Market demand for sustainable and high-performance materials drives continuous improvements in ultra-thin glass, suggesting a significant shift away from thick gauge glass in electronic and architectural industries.

Ultra-Thin Glass vs Thick Gauge Infographic

materialdif.com

materialdif.com