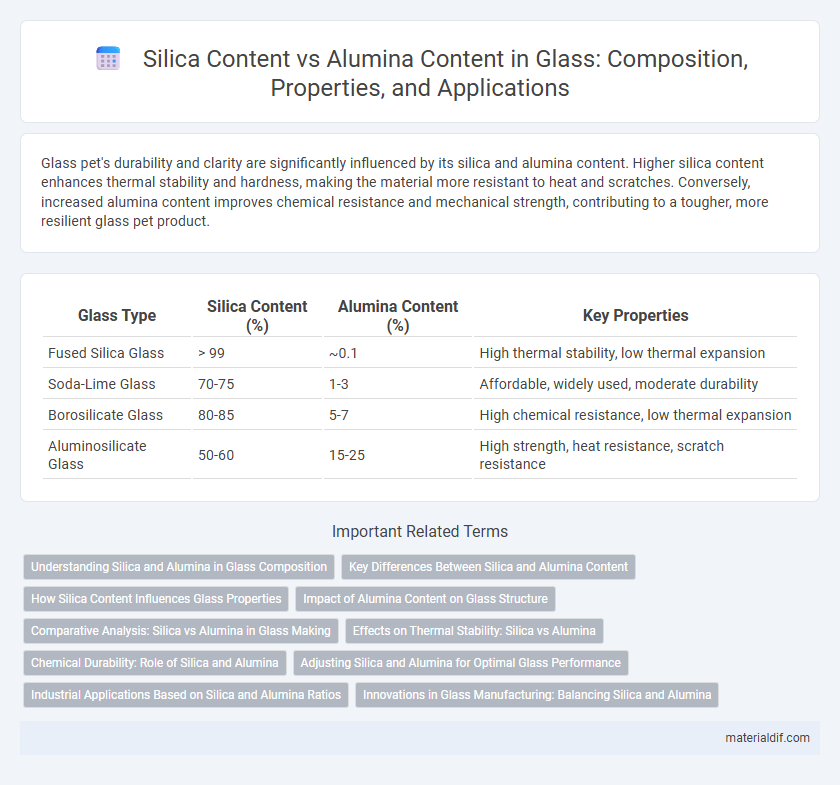

Glass pet's durability and clarity are significantly influenced by its silica and alumina content. Higher silica content enhances thermal stability and hardness, making the material more resistant to heat and scratches. Conversely, increased alumina content improves chemical resistance and mechanical strength, contributing to a tougher, more resilient glass pet product.

Table of Comparison

| Glass Type | Silica Content (%) | Alumina Content (%) | Key Properties |

|---|---|---|---|

| Fused Silica Glass | > 99 | ~0.1 | High thermal stability, low thermal expansion |

| Soda-Lime Glass | 70-75 | 1-3 | Affordable, widely used, moderate durability |

| Borosilicate Glass | 80-85 | 5-7 | High chemical resistance, low thermal expansion |

| Aluminosilicate Glass | 50-60 | 15-25 | High strength, heat resistance, scratch resistance |

Understanding Silica and Alumina in Glass Composition

Silica (SiO2) typically constitutes 60-75% of glass composition, providing the primary glass network responsible for durability and chemical resistance. Alumina (Al2O3), usually present in lower quantities around 1-8%, enhances mechanical strength and improves thermal stability by modifying the silica network structure. The balance between silica and alumina content determines key properties such as melting temperature, viscosity, and resistance to corrosion in various glass types.

Key Differences Between Silica and Alumina Content

Silica content in glass primarily determines its transparency, chemical durability, and melting point, typically ranging from 60% to 75% in most glass compositions. Alumina content, usually present in smaller amounts around 1% to 5%, enhances the glass's mechanical strength and resistance to thermal shock. The key difference lies in silica being the main network former responsible for the glass structure, while alumina acts as a network modifier improving physical properties.

How Silica Content Influences Glass Properties

Silica content directly affects the durability, thermal stability, and transparency of glass, with higher silica levels enhancing the material's chemical resistance and melting point. Elevated silica concentrations improve the network structure of glass, resulting in increased hardness and resistance to deformation under heat. In contrast, lower silica content tends to reduce the glass's mechanical strength and optical clarity, emphasizing the critical role silica plays in defining the overall performance characteristics of glass products.

Impact of Alumina Content on Glass Structure

Higher alumina content in glass increases network connectivity by promoting the formation of Al-O bonds, which enhances chemical durability and mechanical strength. Unlike silica, which primarily forms a rigid Si-O-Si network, alumina acts as a network intermediate, modifying the glass structure to improve thermal stability. This structural modification reduces the glass's susceptibility to devitrification, making it ideal for industrial applications requiring enhanced resistance to thermal and mechanical stress.

Comparative Analysis: Silica vs Alumina in Glass Making

Silica content in glass primarily determines its hardness, chemical durability, and thermal resistance, making it a critical component in most glass formulations. In contrast, alumina enhances the glass's mechanical strength and increases its viscosity during melting, which improves the glass's resistance to deformation and thermal shock. Comparative analysis shows that while high silica content improves durability and resistance, alumina optimizes workability and mechanical properties, necessitating a balanced ratio for specific glass applications.

Effects on Thermal Stability: Silica vs Alumina

Silica content in glass enhances thermal stability by increasing the melting point and reducing thermal expansion, resulting in improved resistance to thermal shock. In contrast, alumina content contributes to structural rigidity and improves chemical durability but has a less pronounced effect on thermal stability compared to silica. High silica glasses maintain dimensional stability under high temperatures, whereas alumina-enriched glass provides better mechanical strength at elevated temperatures.

Chemical Durability: Role of Silica and Alumina

High silica content in glass enhances chemical durability by forming a strong, stable network resistant to chemical attack. Alumina acts as a network intermediate, improving the structural integrity and increasing resistance to moisture and basic solutions. The balance between silica and alumina content is crucial for optimizing glass resistance to chemical corrosion and prolonging its lifespan in harsh environments.

Adjusting Silica and Alumina for Optimal Glass Performance

Adjusting silica and alumina content in glass formulation is crucial for optimizing properties such as durability, thermal stability, and chemical resistance. Higher silica content enhances glass hardness and melting point, while controlled alumina addition improves viscosity and resistance to devitrification. Balancing these oxides ensures superior glass performance tailored for specific industrial applications.

Industrial Applications Based on Silica and Alumina Ratios

High silica content in glass enhances thermal resistance and chemical durability, making it ideal for applications in fiber optics and high-strength glassware. Elevated alumina levels improve viscosity and mechanical strength, which benefits automotive windshields and architectural glass, providing structural stability. Optimizing silica-to-alumina ratios enables tailored glass properties for specific industrial uses, such as corrosion-resistant containers and high-performance electronic displays.

Innovations in Glass Manufacturing: Balancing Silica and Alumina

Innovations in glass manufacturing increasingly focus on optimizing the silica-to-alumina ratio to enhance thermal stability and mechanical strength. High silica content improves transparency and chemical resistance, while controlled alumina addition increases durability and reduces melting temperature. Advanced formulations balance these components to produce glass with superior performance for electronics, optics, and construction industries.

Silica content vs Alumina content Infographic

materialdif.com

materialdif.com