Clear glass contains a small amount of iron oxide, giving it a slight green tint that becomes more noticeable on thicker edges. Low-iron glass is specially manufactured to reduce iron content, resulting in higher clarity and a true color representation with minimal green hue. This makes low-iron glass ideal for applications where optical clarity and aesthetics are critical, such as display cases and high-end architectural projects.

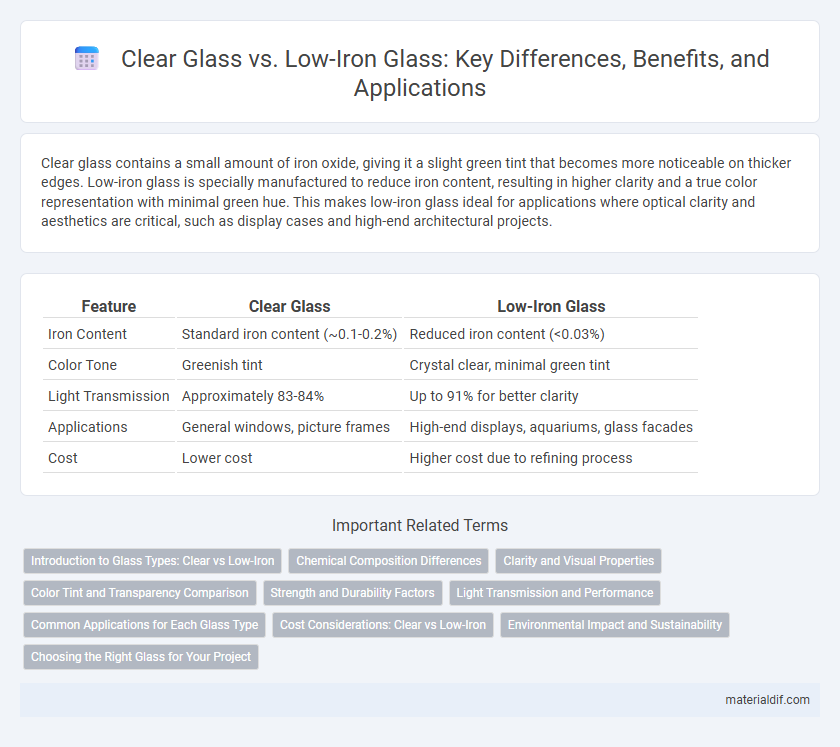

Table of Comparison

| Feature | Clear Glass | Low-Iron Glass |

|---|---|---|

| Iron Content | Standard iron content (~0.1-0.2%) | Reduced iron content (<0.03%) |

| Color Tone | Greenish tint | Crystal clear, minimal green tint |

| Light Transmission | Approximately 83-84% | Up to 91% for better clarity |

| Applications | General windows, picture frames | High-end displays, aquariums, glass facades |

| Cost | Lower cost | Higher cost due to refining process |

Introduction to Glass Types: Clear vs Low-Iron

Clear glass, commonly used in windows and picture frames, contains trace amounts of iron that give it a slight green tint. Low-iron glass has significantly reduced iron content, resulting in higher clarity and enhanced light transmission, making it ideal for applications requiring true color representation. Both types are essential in construction and design, with low-iron glass preferred for premium aesthetics and clear glass favored for standard uses.

Chemical Composition Differences

Clear glass primarily contains iron oxide impurities that give it a slight greenish tint, while low-iron glass undergoes a refined manufacturing process to minimize iron content, typically reducing Fe2O3 levels from around 0.05% to 0.01%. This significant reduction in iron oxide enhances light transmission and clarity, making low-iron glass ideal for architectural and display applications requiring high optical precision. The chemical composition difference is critical in controlling tint and transparency, with low-iron glass offering purer, more color-neutral properties compared to standard clear glass.

Clarity and Visual Properties

Clear glass offers good transparency but contains iron oxide, which can cause a slight greenish tint affecting visual clarity, especially in thicker panels. Low-iron glass is manufactured with reduced iron content, resulting in higher light transmission and a true, neutral appearance that significantly enhances clarity and color accuracy. The superior visual properties of low-iron glass make it ideal for applications demanding maximum transparency and minimal color distortion.

Color Tint and Transparency Comparison

Clear glass typically exhibits a subtle green tint due to its iron content, which can affect color accuracy and overall transparency in architectural and display applications. Low-iron glass reduces this greenish hue, offering superior clarity and higher light transmission, making it ideal for settings demanding true color representation and maximum visibility. The enhanced transparency of low-iron glass improves aesthetic appeal and performance in skylights, facades, and aquariums where color fidelity is critical.

Strength and Durability Factors

Low-iron glass exhibits enhanced strength and durability compared to standard clear glass due to its reduced iron content, which minimizes impurities and structural weaknesses. This type of glass is less prone to discoloration and maintains clarity over time, contributing to superior resistance against environmental stressors and physical impacts. Engineers and architects prefer low-iron glass in applications requiring high performance and longevity, such as building facades and safety glazing.

Light Transmission and Performance

Low-iron glass offers superior light transmission compared to standard clear glass, typically allowing up to 91% light to pass through versus 83-84% in clear glass. This enhanced clarity boosts visual performance, making colors appear more vibrant and true, which is crucial for architectural applications and displays. The reduced iron content minimizes the greenish tint found in clear glass, ensuring optimal transparency and aesthetic appeal.

Common Applications for Each Glass Type

Clear glass is widely used in residential windows, storefronts, and picture frames due to its affordability and adequate clarity for general purposes. Low-iron glass, characterized by its higher light transmission and reduced green tint, is preferred in high-end architectural projects, display cases, and solar panels where true color representation and maximum transparency are critical. Both glass types serve functional roles but differ significantly in applications demanding optical precision versus standard transparency.

Cost Considerations: Clear vs Low-Iron

Clear glass generally offers a lower upfront cost compared to low-iron glass, making it a budget-friendly choice for standard applications. Low-iron glass, known for its enhanced clarity and minimal green tint, commands higher prices due to more complex manufacturing and purer raw materials. When weighing cost considerations, project goals and aesthetic requirements often justify the premium expense of low-iron glass in architectural or display uses.

Environmental Impact and Sustainability

Low-iron glass reduces iron content, resulting in higher clarity and allowing more natural light to penetrate, which enhances energy efficiency by lowering electricity consumption for lighting and heating. Clear glass typically contains higher iron levels, causing a slight green tint that can affect solar heat gain and energy performance. Choosing low-iron glass supports sustainable building practices by improving insulation properties and reducing reliance on artificial lighting, thereby minimizing environmental impact.

Choosing the Right Glass for Your Project

Low-iron glass offers higher clarity and reduced greenish tint compared to standard clear glass, making it ideal for projects requiring true color accuracy and enhanced transparency. Clear glass is cost-effective and suitable for applications where minor color distortion is acceptable, such as everyday windows or decorative panels. Selecting the right glass depends on project requirements for visual purity, budget, and aesthetic impact.

Clear vs Low-Iron Infographic

materialdif.com

materialdif.com