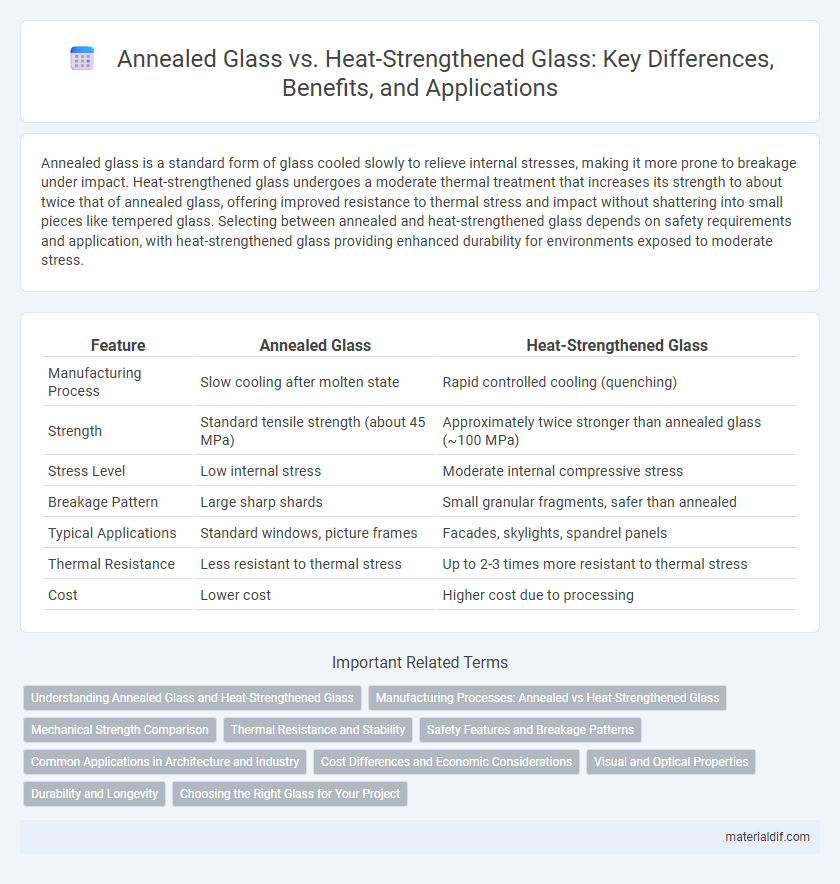

Annealed glass is a standard form of glass cooled slowly to relieve internal stresses, making it more prone to breakage under impact. Heat-strengthened glass undergoes a moderate thermal treatment that increases its strength to about twice that of annealed glass, offering improved resistance to thermal stress and impact without shattering into small pieces like tempered glass. Selecting between annealed and heat-strengthened glass depends on safety requirements and application, with heat-strengthened glass providing enhanced durability for environments exposed to moderate stress.

Table of Comparison

| Feature | Annealed Glass | Heat-Strengthened Glass |

|---|---|---|

| Manufacturing Process | Slow cooling after molten state | Rapid controlled cooling (quenching) |

| Strength | Standard tensile strength (about 45 MPa) | Approximately twice stronger than annealed glass (~100 MPa) |

| Stress Level | Low internal stress | Moderate internal compressive stress |

| Breakage Pattern | Large sharp shards | Small granular fragments, safer than annealed |

| Typical Applications | Standard windows, picture frames | Facades, skylights, spandrel panels |

| Thermal Resistance | Less resistant to thermal stress | Up to 2-3 times more resistant to thermal stress |

| Cost | Lower cost | Higher cost due to processing |

Understanding Annealed Glass and Heat-Strengthened Glass

Annealed glass undergoes a controlled cooling process that relieves internal stresses, resulting in standard strength and ease of cutting or shaping. Heat-strengthened glass is heated to higher temperatures and rapidly cooled, making it twice as strong as annealed glass but less resilient than tempered glass. Both types offer varying levels of durability and safety for architectural and automotive applications.

Manufacturing Processes: Annealed vs Heat-Strengthened Glass

Annealed glass is produced by slowly cooling molten glass in a controlled environment to relieve internal stresses, resulting in a standard safety glass with lower strength. Heat-strengthened glass undergoes a rapid reheating and controlled cooling process, making it twice as strong as annealed glass while maintaining the ability to be cut or drilled after tempering. The manufacturing distinction between slow annealing and rapid thermal treatment directly affects the mechanical properties and applications of each glass type.

Mechanical Strength Comparison

Annealed glass exhibits lower mechanical strength compared to heat-strengthened glass, as it undergoes slow cooling without induced internal stresses. Heat-strengthened glass is approximately twice as strong as annealed glass due to its controlled thermal tempering process that introduces compressive stresses on the surface. This enhanced strength makes heat-strengthened glass more resistant to impact and thermal stress, suitable for applications requiring greater durability.

Thermal Resistance and Stability

Annealed glass offers lower thermal resistance and is more prone to thermal breakage due to its slower cooling process, making it less stable under rapid temperature changes. Heat-strengthened glass undergoes controlled cooling that increases its thermal resistance, providing enhanced stability against thermal shocks. This improved durability makes heat-strengthened glass a preferred choice for applications requiring moderate thermal stress resistance without the brittleness of fully tempered glass.

Safety Features and Breakage Patterns

Annealed glass is prone to breaking into large, sharp shards that pose significant safety hazards, whereas heat-strengthened glass, subjected to twice the cooling rate of annealing, fractures into fewer and larger pieces, reducing injury risks. Heat-strengthened glass offers enhanced durability and better resistance to thermal stress, making it safer for applications where moderate safety is required but not as stringent as tempered glass standards. The unique breakage pattern of heat-strengthened glass provides a compromise between the fragile nature of annealed glass and the high safety features of fully tempered glass.

Common Applications in Architecture and Industry

Annealed glass is commonly used in non-safety architectural applications such as interior partitions, picture frames, and decorative windowpanes due to its cost-effectiveness and ease of cutting. Heat-strengthened glass finds frequent use in building facades, skylights, and spandrel panels where enhanced strength and thermal resistance are needed without the full safety requirements of tempered glass. Both types play critical roles in the construction industry, with annealed glass favored for its workability and heat-strengthened glass preferred for structural glazing and curtain wall systems.

Cost Differences and Economic Considerations

Annealed glass is generally less expensive than heat-strengthened glass due to its simpler manufacturing process and lower energy consumption. Heat-strengthened glass, which undergoes controlled cooling to enhance strength, commands higher prices because of increased production costs and improved durability. Economic considerations favor annealed glass for budget-conscious projects, while heat-strengthened glass offers long-term value in applications requiring greater impact resistance and thermal stress tolerance.

Visual and Optical Properties

Annealed glass offers superior clarity and minimal distortion due to its slow cooling process, preserving the natural transparency of the glass. Heat-strengthened glass, while visually similar, may exhibit slight optical distortions or subtle waviness caused by rapid reheating and cooling, which can affect light refraction. Both types maintain high visible light transmittance, but annealed glass is preferred for applications demanding flawless visual aesthetics.

Durability and Longevity

Annealed glass offers basic durability but is more prone to breakage under thermal stress and impact compared to heat-strengthened glass, which undergoes a controlled heating and rapid cooling process to enhance its strength. Heat-strengthened glass exhibits approximately twice the strength of annealed glass, improving its resistance to temperature variations and mechanical forces, thereby extending its longevity in architectural applications. The increased durability of heat-strengthened glass makes it a preferred choice for environments subject to higher thermal loads and mechanical stresses.

Choosing the Right Glass for Your Project

Annealed glass offers excellent clarity and cost-efficiency but lacks the strength and thermal resistance of heat-strengthened glass, making it ideal for interior applications without high stress. Heat-strengthened glass provides about twice the strength of annealed glass and improved thermal performance, suitable for exterior facades, skylights, and areas prone to moderate impact or temperature variations. Selecting the right glass depends on balancing budget, safety requirements, and environmental exposure to ensure optimal performance and longevity.

Annealed Glass vs Heat-Strengthened Glass Infographic

materialdif.com

materialdif.com