Glass coating enhances surface durability and resistance to scratches and stains by applying a thin protective layer, preserving clarity without altering the glass's structure. Glass lamination involves bonding multiple glass layers with an interlayer, increasing strength and safety by preventing shattering and improving impact resistance. Choosing between coating and lamination depends on whether the priority is surface protection or structural reinforcement for glass pets.

Table of Comparison

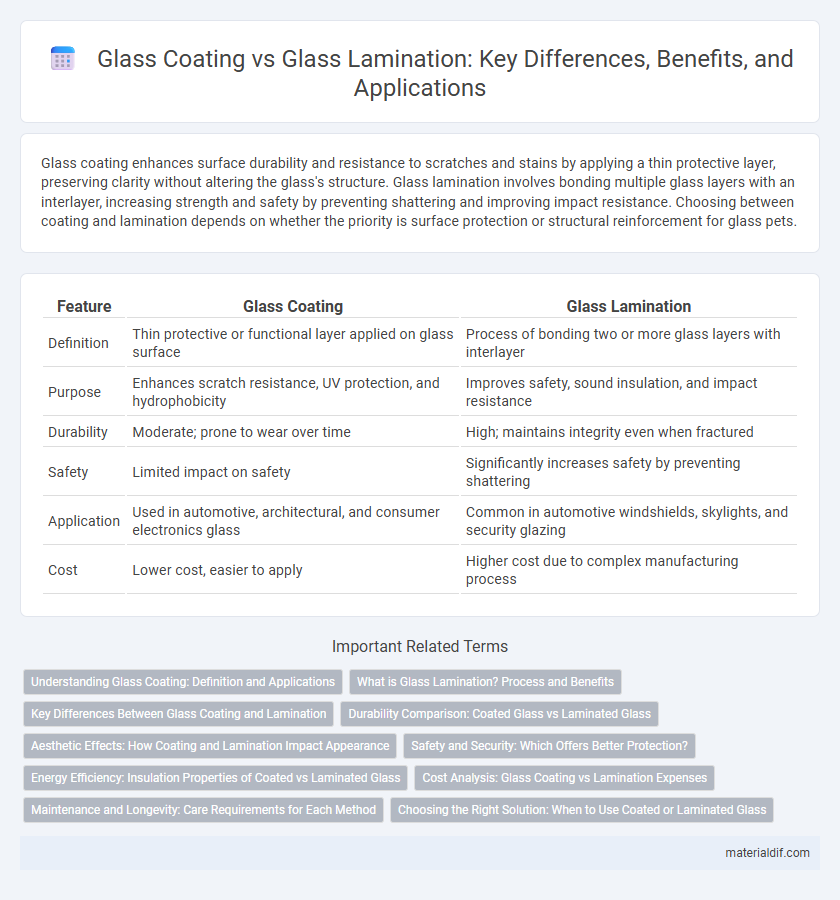

| Feature | Glass Coating | Glass Lamination |

|---|---|---|

| Definition | Thin protective or functional layer applied on glass surface | Process of bonding two or more glass layers with interlayer |

| Purpose | Enhances scratch resistance, UV protection, and hydrophobicity | Improves safety, sound insulation, and impact resistance |

| Durability | Moderate; prone to wear over time | High; maintains integrity even when fractured |

| Safety | Limited impact on safety | Significantly increases safety by preventing shattering |

| Application | Used in automotive, architectural, and consumer electronics glass | Common in automotive windshields, skylights, and security glazing |

| Cost | Lower cost, easier to apply | Higher cost due to complex manufacturing process |

Understanding Glass Coating: Definition and Applications

Glass coating involves applying a thin, transparent layer to glass surfaces to enhance properties such as scratch resistance, UV protection, and anti-reflective features. Common applications include automotive windshields, photovoltaic panels, and architectural glass where improved durability and energy efficiency are critical. Unlike glass lamination, which fuses multiple glass layers for safety and strength, glass coating primarily modifies surface characteristics without altering structural integrity.

What is Glass Lamination? Process and Benefits

Glass lamination involves bonding two or more layers of glass with an interlayer, typically polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), through heat and pressure. This process enhances safety by preventing shattered glass from splintering and offers benefits such as improved sound insulation, UV protection, and increased structural strength. Laminated glass is widely used in automotive windshields, building facades, and skylights for its durability and safety features.

Key Differences Between Glass Coating and Lamination

Glass coating involves applying a thin, transparent layer to enhance surface properties such as scratch resistance, UV protection, and glare reduction, while glass lamination refers to bonding multiple glass layers with an interlayer for improved safety and impact resistance. Coating primarily enhances surface durability and optical clarity without altering glass thickness, whereas lamination increases structural integrity and holds glass fragments in place upon breakage. Key differences include their functional focus--coatings modify external surface characteristics, and laminations provide internal reinforcement and safety features.

Durability Comparison: Coated Glass vs Laminated Glass

Glass coating enhances surface hardness and scratch resistance, significantly improving durability against environmental factors such as UV radiation and chemical exposure. Laminated glass combines multiple glass layers with interlayers, offering superior resistance to impact, shattering, and structural integrity under stress. In durability comparison, laminated glass excels in safety and impact resistance, while coated glass provides enhanced surface protection and longevity against wear and corrosion.

Aesthetic Effects: How Coating and Lamination Impact Appearance

Glass coating enhances aesthetic appeal by providing a sleek, reflective surface that can be tinted or mirrored to control light and reduce glare, creating a modern and polished look. Glass lamination adds visual depth and texture through the incorporation of interlayers such as colored films or patterns, offering customizable design options while improving safety and sound insulation. Both techniques influence the glass's transparency and reflectivity, with coating emphasizing surface finish and lamination focusing on structural visual artistry.

Safety and Security: Which Offers Better Protection?

Glass lamination provides superior safety and security by bonding multiple layers of glass with a durable interlayer that holds shards together upon impact, reducing the risk of injury and intrusions. Glass coating enhances resistance to scratches and minor impacts but cannot prevent glass from shattering or provide the same level of structural integrity. For maximum protection against breakage and forced entry, laminated glass remains the preferred choice in security applications.

Energy Efficiency: Insulation Properties of Coated vs Laminated Glass

Glass coating enhances energy efficiency by reflecting infrared radiation, reducing heat transfer and lowering cooling costs. Laminated glass improves insulation through its interlayer, which acts as a thermal barrier, minimizing heat loss in colder climates. Coated glass typically excels in solar control, while laminated glass offers superior sound insulation alongside thermal performance.

Cost Analysis: Glass Coating vs Lamination Expenses

Glass coating typically costs less upfront compared to glass lamination, with prices averaging $2 to $10 per square foot depending on the type of coating used, such as anti-reflective or UV-blocking films. Glass lamination involves higher material and labor costs, generally ranging from $15 to $35 per square foot, due to the multi-layer construction combining glass and plastic interlayers for enhanced safety and durability. Evaluating expenses for commercial or residential projects requires considering long-term benefits, as lamination offers superior impact resistance while coatings primarily provide surface protection and aesthetic enhancements.

Maintenance and Longevity: Care Requirements for Each Method

Glass coating provides a protective layer that reduces surface damage and requires minimal maintenance, typically involving periodic cleaning with non-abrasive materials to retain its effectiveness. Glass lamination enhances durability by bonding multiple layers, offering superior impact resistance and UV protection, but demands careful inspection for delamination or seal integrity to ensure longevity. Both methods extend the lifespan of glass, with coatings offering easier upkeep while laminations necessitate vigilant monitoring to prevent deterioration.

Choosing the Right Solution: When to Use Coated or Laminated Glass

Glass coating enhances surface properties such as scratch resistance, UV protection, and anti-reflective qualities, making it ideal for architectural and automotive applications requiring durability and clarity. Glass lamination involves bonding layers with a polymer interlayer that improves safety by holding shards together upon impact, which is essential for security glazing and noise reduction in windows. Choosing between coated or laminated glass depends on whether protection against environmental factors or structural safety and impact resistance is the primary objective.

Glass Coating vs Glass Lamination Infographic

materialdif.com

materialdif.com