Fused silica offers superior thermal stability and optical clarity compared to crystalline quartz, making it ideal for high-precision applications such as semiconductor manufacturing and UV optics. Unlike crystalline quartz, fused silica is amorphous, which eliminates birefringence and enhances its resistance to thermal shock and chemical corrosion. This combination of properties results in improved durability and performance in demanding environments where consistency and purity are critical.

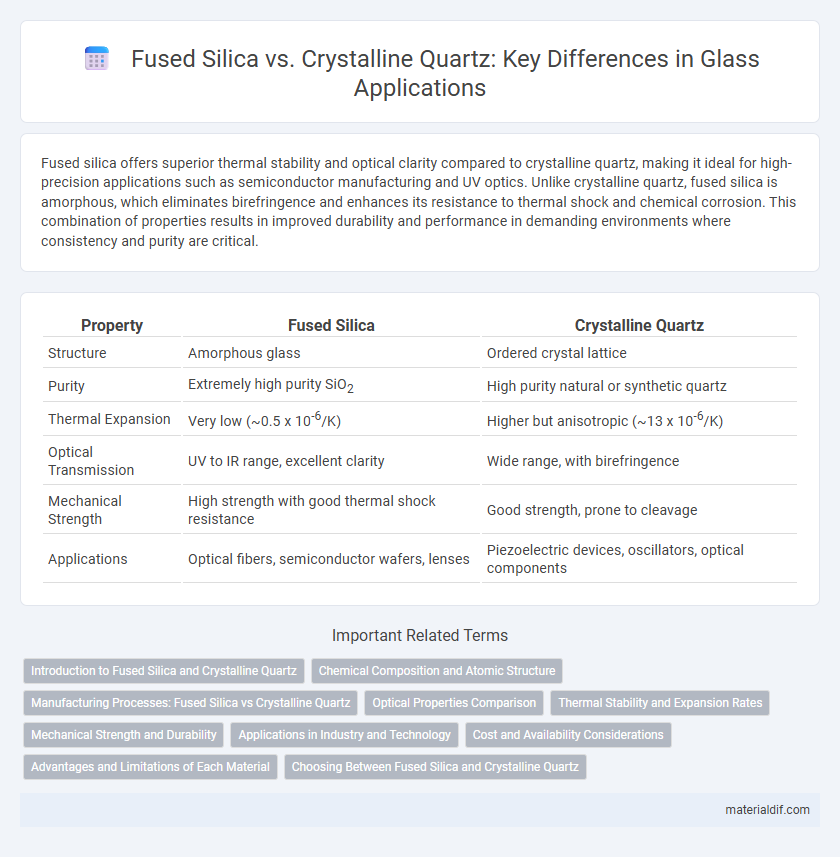

Table of Comparison

| Property | Fused Silica | Crystalline Quartz |

|---|---|---|

| Structure | Amorphous glass | Ordered crystal lattice |

| Purity | Extremely high purity SiO2 | High purity natural or synthetic quartz |

| Thermal Expansion | Very low (~0.5 x 10-6/K) | Higher but anisotropic (~13 x 10-6/K) |

| Optical Transmission | UV to IR range, excellent clarity | Wide range, with birefringence |

| Mechanical Strength | High strength with good thermal shock resistance | Good strength, prone to cleavage |

| Applications | Optical fibers, semiconductor wafers, lenses | Piezoelectric devices, oscillators, optical components |

Introduction to Fused Silica and Crystalline Quartz

Fused silica is a non-crystalline, amorphous form of silicon dioxide with exceptional thermal stability, low thermal expansion, and high optical transparency, commonly used in precision optics and semiconductor manufacturing. Crystalline quartz, a naturally occurring form of silicon dioxide with a well-ordered crystal lattice, exhibits piezoelectric properties and distinct anisotropic thermal and optical behavior. Both materials serve critical roles in scientific and industrial applications, with fused silica favored for its purity and homogeneity, while crystalline quartz offers unique mechanical and electrical characteristics.

Chemical Composition and Atomic Structure

Fused silica is composed of non-crystalline silicon dioxide (SiO2) with an amorphous atomic structure, lacking long-range periodic order, which enhances its thermal stability and chemical inertness. Crystalline quartz, also made of silicon dioxide (SiO2), features a well-ordered hexagonal crystal lattice structure, providing distinct anisotropic optical and mechanical properties. The atomic arrangement in fused silica results in fewer defects and lower impurities compared to the crystalline form, making it superior for high-purity optical applications.

Manufacturing Processes: Fused Silica vs Crystalline Quartz

Fused silica is produced through the melting and rapid cooling of high-purity silicon dioxide, resulting in an amorphous, non-crystalline structure with superior thermal stability and optical clarity. Crystalline quartz manufacturing involves the controlled crystallization of silica through hydrothermal synthesis, forming well-defined crystal lattices used in piezoelectric and optical applications. The inherent differences in these processes influence the material properties, where fused silica offers higher purity and homogeneity, while crystalline quartz provides anisotropic mechanical and electrical characteristics.

Optical Properties Comparison

Fused silica offers superior optical clarity with a wider transmission range from ultraviolet to infrared wavelengths compared to crystalline quartz, which has more limited UV transmission. The refractive index of fused silica is typically lower and more stable across temperature variations, enhancing its performance in precision optics. Crystalline quartz exhibits birefringence and piezoelectric properties absent in fused silica, influencing its optical behavior in polarization-sensitive applications.

Thermal Stability and Expansion Rates

Fused silica exhibits superior thermal stability with a melting point around 1723degC and an ultra-low coefficient of thermal expansion (~0.5 x 10^-6 /degC), making it ideal for high-temperature applications. Crystalline quartz has a lower melting point near 1670degC and a higher thermal expansion rate (~13.7 x 10^-6 /degC), leading to more significant dimensional changes under heat. The low expansion and high stability of fused silica reduce thermal stress, enhancing performance in optical and semiconductor industries where precise thermal management is crucial.

Mechanical Strength and Durability

Fused silica exhibits higher mechanical strength and superior durability compared to crystalline quartz due to its amorphous structure, which eliminates cleavage planes that cause weakness in crystalline forms. The homogeneous network of fused silica enhances resistance to mechanical stress and thermal shock, making it ideal for demanding applications. Crystalline quartz, while mechanically robust, is more prone to fracture along crystal planes, reducing its durability under heavy or repetitive impact.

Applications in Industry and Technology

Fused silica offers superior thermal stability and optical clarity, making it ideal for semiconductor manufacturing, fiber optics, and high-precision optical components. Crystalline quartz is favored in frequency control devices, such as quartz oscillators and resonators, due to its piezoelectric properties. Each material's unique structural characteristics enable specific industrial applications, with fused silica excelling in high-temperature and UV-transparent environments, while crystalline quartz is essential in electronic timing and sensing technologies.

Cost and Availability Considerations

Fused silica commands a higher price point due to its superior purity and manufacturing complexity compared to crystalline quartz, which is generally more affordable and widely available. The production process of fused silica involves melting high-purity silicon dioxide, resulting in excellent thermal and optical properties, but limited supply drives costs upward. In contrast, crystalline quartz is naturally abundant and easier to process, making it a cost-effective option for many industrial applications.

Advantages and Limitations of Each Material

Fused silica offers superior thermal stability and excellent optical transmission in ultraviolet ranges, making it ideal for high-precision optical applications, but it is more expensive and difficult to machine compared to crystalline quartz. Crystalline quartz features piezoelectric properties and greater mechanical strength, suitable for electronic and sensor applications, yet it exhibits birefringence and lower thermal shock resistance. Both materials provide high purity and chemical resistance, with selection dependent on specific performance requirements such as optical clarity, mechanical durability, and cost-effectiveness.

Choosing Between Fused Silica and Crystalline Quartz

Fused silica offers superior thermal stability and ultraviolet transparency compared to crystalline quartz, making it ideal for high-precision optical applications and semiconductor manufacturing. Crystalline quartz provides greater mechanical strength and piezoelectric properties, which are essential for electronic components and resonators. Selecting between fused silica and crystalline quartz depends on specific application requirements such as thermal resistance, optical clarity, and mechanical durability.

Fused silica vs Crystalline quartz Infographic

materialdif.com

materialdif.com