Chemically strengthened glass undergoes an ion-exchange process that replaces smaller ions in the glass surface with larger ones, creating a compressive stress layer that significantly enhances its strength and resistance to scratches. Heat-strengthened glass is produced by heating the glass to a high temperature and then rapidly cooling it, resulting in moderate strength improvements and increased durability compared to annealed glass but less than chemically strengthened options. While chemically strengthened glass offers superior strength and better edge stability, heat-strengthened glass provides a cost-effective middle ground with improved thermal resistance.

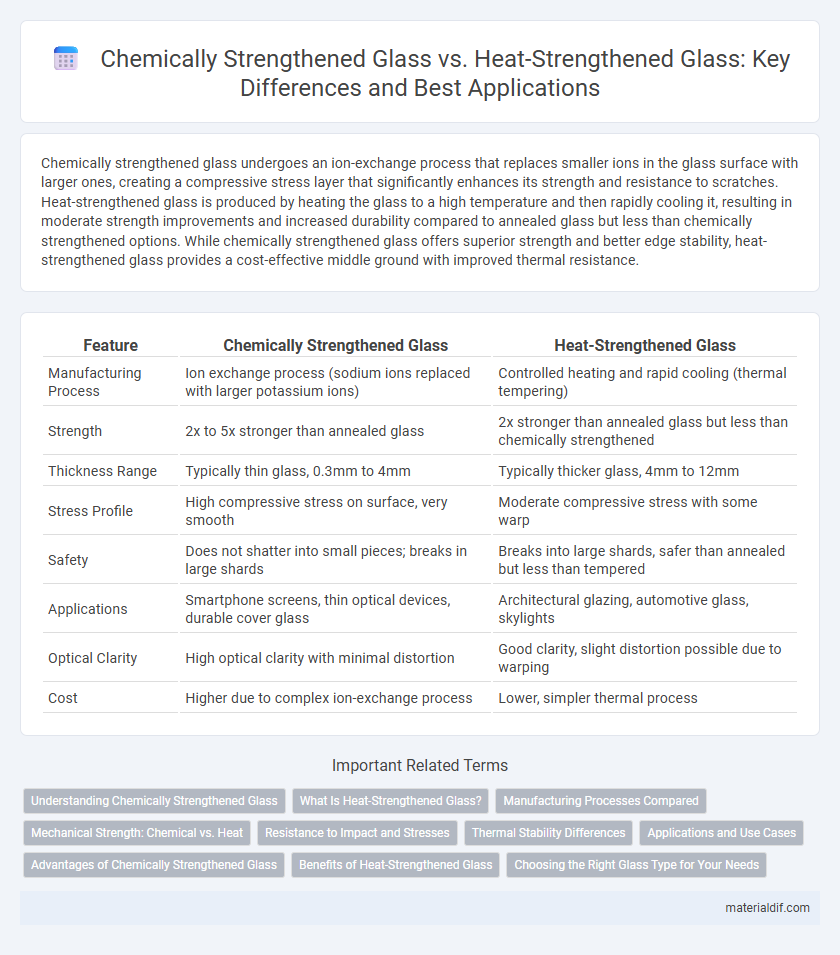

Table of Comparison

| Feature | Chemically Strengthened Glass | Heat-Strengthened Glass |

|---|---|---|

| Manufacturing Process | Ion exchange process (sodium ions replaced with larger potassium ions) | Controlled heating and rapid cooling (thermal tempering) |

| Strength | 2x to 5x stronger than annealed glass | 2x stronger than annealed glass but less than chemically strengthened |

| Thickness Range | Typically thin glass, 0.3mm to 4mm | Typically thicker glass, 4mm to 12mm |

| Stress Profile | High compressive stress on surface, very smooth | Moderate compressive stress with some warp |

| Safety | Does not shatter into small pieces; breaks in large shards | Breaks into large shards, safer than annealed but less than tempered |

| Applications | Smartphone screens, thin optical devices, durable cover glass | Architectural glazing, automotive glass, skylights |

| Optical Clarity | High optical clarity with minimal distortion | Good clarity, slight distortion possible due to warping |

| Cost | Higher due to complex ion-exchange process | Lower, simpler thermal process |

Understanding Chemically Strengthened Glass

Chemically strengthened glass undergoes an ion-exchange process where smaller sodium ions in the glass surface are replaced by larger potassium ions, creating compressive stress that enhances its strength and resistance to scratches. This type of glass offers superior durability and toughness compared to heat-strengthened glass, making it ideal for applications requiring high impact resistance, such as smartphone screens and automotive windows. Chemically strengthened glass maintains optical clarity and thinness while providing enhanced safety benefits without compromising transparency or design flexibility.

What Is Heat-Strengthened Glass?

Heat-strengthened glass is a type of safety glass that undergoes a controlled thermal treatment process, heating the glass to approximately 600degC and then cooling it at a moderate rate to increase its strength. It is about twice as strong as annealed glass but less robust than fully tempered glass, offering enhanced resistance to thermal stress and impact. This glass is commonly used in areas requiring moderate safety and durability, such as windows, doors, and facades where structural integrity and partial safety are needed.

Manufacturing Processes Compared

Chemically strengthened glass undergoes an ion-exchange process where smaller sodium ions on the glass surface are replaced with larger potassium ions from a molten salt bath, creating compressive stress and enhancing durability. Heat-strengthened glass is produced by heating the glass to a temperature near its softening point and then rapidly cooling it through controlled quenching, resulting in moderate surface compression and increased strength compared to annealed glass. The ion-exchange method of chemical strengthening provides higher surface compression and better resistance to damage than the thermal tempering process used in heat-strengthened glass manufacturing.

Mechanical Strength: Chemical vs. Heat

Chemically strengthened glass exhibits mechanical strength up to four to five times greater than heat-strengthened glass due to ion exchange processes that create deep compressive stress layers, enhancing resistance to surface damage and impact. Heat-strengthened glass undergoes thermal tempering that induces moderate surface compression, resulting in mechanical strength approximately twice that of annealed glass but less than chemical strengthening. The deeper compressive layer in chemically strengthened glass provides superior durability and fracture resistance, making it ideal for applications requiring enhanced mechanical performance.

Resistance to Impact and Stresses

Chemically strengthened glass exhibits superior resistance to impact and stresses due to its ion-exchange process, which creates a deep compressive layer on the surface, significantly enhancing durability. Heat-strengthened glass undergoes thermal treatment that induces moderate surface compression, providing increased strength compared to annealed glass but less than chemically strengthened variants. Applications requiring high impact resistance and stress tolerance prioritize chemically strengthened glass for its enhanced performance under dynamic loads and thermal fluctuations.

Thermal Stability Differences

Chemically strengthened glass achieves higher thermal stability due to its ion-exchange process that creates deep compressive stress layers, allowing it to better withstand rapid temperature changes compared to heat-strengthened glass. Heat-strengthened glass undergoes thermal tempering with moderate cooling rates that produce less surface compression, making it less resistant to thermal shock. The increased thermal durability of chemically strengthened glass makes it ideal for applications exposed to fluctuating temperatures and extreme thermal environments.

Applications and Use Cases

Chemically strengthened glass offers superior surface compression, making it ideal for smartphones, tablets, and high-strength architectural applications requiring enhanced scratch resistance and impact durability. Heat-strengthened glass provides moderate strength improvement suited for applications like commercial windows, curtain walls, and skylights where thermal stability and safety are essential but maximum strength is not critical. Both types enhance safety and durability, yet chemical strengthening is preferred in precision devices, while heat strengthening serves well in structural glazing and facades.

Advantages of Chemically Strengthened Glass

Chemically strengthened glass offers superior surface compression, making it up to four times stronger than heat-strengthened glass and highly resistant to scratches and impact. Its enhanced durability improves safety, allowing thinner glass panels without compromising strength, ideal for architectural and consumer electronics applications. The chemical strengthening process also maintains optical clarity and enables complex shapes, surpassing the thermal limitations of heat-strengthened glass.

Benefits of Heat-Strengthened Glass

Heat-strengthened glass offers enhanced durability, with approximately twice the strength of annealed glass, making it more resistant to mechanical stress and thermal changes. It provides improved safety by breaking into larger, less hazardous shards compared to fully tempered glass, reducing injury risk. This type of glass is ideal for architectural applications where higher strength and thermal resistance are needed without the brittleness of fully tempered glass.

Choosing the Right Glass Type for Your Needs

Chemically strengthened glass offers superior strength and scratch resistance by altering the glass surface through ion exchange, making it ideal for applications requiring high durability and safety such as smartphone screens and architectural facades. Heat-strengthened glass, produced by controlled thermal tempering, provides moderate strength and improved resistance to thermal stress, suitable for applications like glass doors and certain windows where impact resistance is important but not critical. Selecting the right glass type depends on factors like required strength, safety standards, application environment, and budget constraints.

Chemically strengthened glass vs Heat-strengthened glass Infographic

materialdif.com

materialdif.com