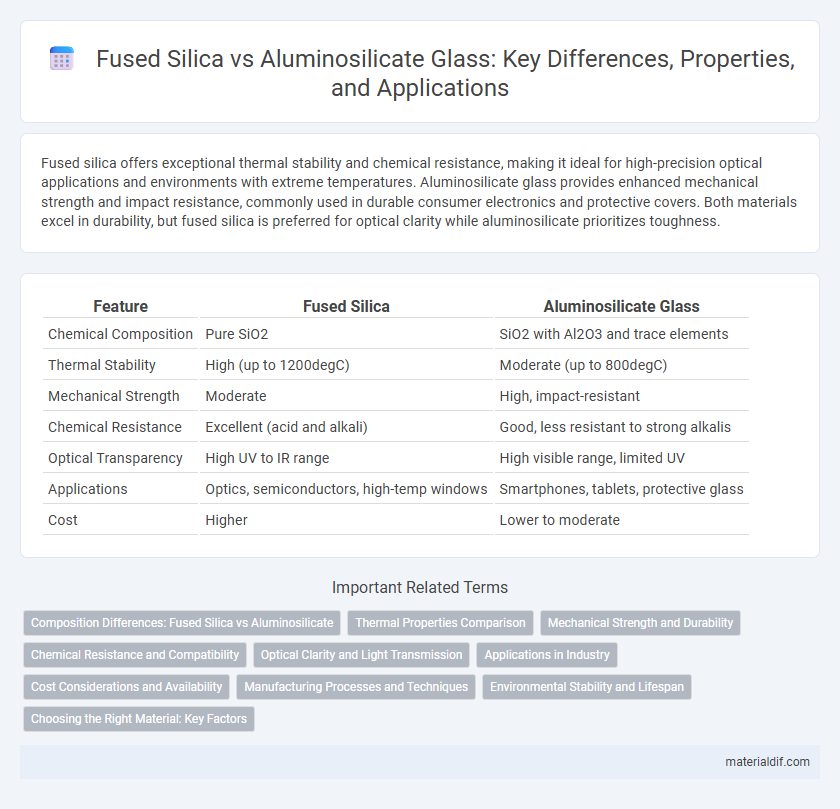

Fused silica offers exceptional thermal stability and chemical resistance, making it ideal for high-precision optical applications and environments with extreme temperatures. Aluminosilicate glass provides enhanced mechanical strength and impact resistance, commonly used in durable consumer electronics and protective covers. Both materials excel in durability, but fused silica is preferred for optical clarity while aluminosilicate prioritizes toughness.

Table of Comparison

| Feature | Fused Silica | Aluminosilicate Glass |

|---|---|---|

| Chemical Composition | Pure SiO2 | SiO2 with Al2O3 and trace elements |

| Thermal Stability | High (up to 1200degC) | Moderate (up to 800degC) |

| Mechanical Strength | Moderate | High, impact-resistant |

| Chemical Resistance | Excellent (acid and alkali) | Good, less resistant to strong alkalis |

| Optical Transparency | High UV to IR range | High visible range, limited UV |

| Applications | Optics, semiconductors, high-temp windows | Smartphones, tablets, protective glass |

| Cost | Higher | Lower to moderate |

Composition Differences: Fused Silica vs Aluminosilicate

Fused silica consists primarily of pure silicon dioxide (SiO2) with a highly uniform amorphous structure, offering exceptional thermal and chemical stability. Aluminosilicate glass incorporates aluminum oxide (Al2O3) in addition to silicon dioxide, enhancing its mechanical strength and resistance to high-temperature deformation. The presence of aluminum changes the network structure, reducing thermal expansion and increasing durability compared to pure fused silica.

Thermal Properties Comparison

Fused silica exhibits a very low coefficient of thermal expansion (approximately 0.5 x 10^-6 /degC), making it highly resistant to thermal shock and ideal for applications requiring precise dimensional stability under temperature fluctuations. Aluminosilicate glass, with a coefficient of thermal expansion typically around 3-5 x 10^-6 /degC, offers greater mechanical strength but lower thermal shock resistance compared to fused silica. The superior thermal stability of fused silica makes it preferable for high-temperature environments and optical applications where minimal expansion is critical.

Mechanical Strength and Durability

Fused silica exhibits exceptional mechanical strength due to its high purity and low thermal expansion coefficient, making it highly resistant to thermal shock and mechanical stress. Aluminosilicate glass offers enhanced durability with superior resistance to chemical corrosion and impact, often used in protective covers and smartphone screens. Both materials provide significant strength, but fused silica is preferred for high-precision optical applications while aluminosilicate excels in rugged, everyday use environments.

Chemical Resistance and Compatibility

Fused silica offers superior chemical resistance due to its almost pure silicon dioxide composition, making it highly compatible with aggressive chemicals like hydrofluoric acid and strong alkalis. Aluminosilicate glass, containing aluminum oxide, exhibits improved mechanical strength but is generally less resistant to harsh chemical environments compared to fused silica. For applications requiring maximum chemical durability and minimal reactivity, fused silica remains the preferred choice over aluminosilicate glass.

Optical Clarity and Light Transmission

Fused silica offers superior optical clarity and higher light transmission rates compared to aluminosilicate glass, making it ideal for precision optical applications. Its low hydroxyl content and high purity contribute to minimal light absorption and excellent UV transparency. Aluminosilicate glass, while durable and impact-resistant, typically exhibits slightly reduced optical clarity and light transmission due to its mixed oxide composition.

Applications in Industry

Fused silica offers exceptional thermal stability and chemical resistance, making it ideal for semiconductor manufacturing, optical fibers, and precision lenses. Aluminosilicate glass provides superior toughness and scratch resistance, commonly utilized in smartphone screens, touch panels, and display covers. Both materials serve critical roles in aerospace and automotive industries due to their unique mechanical and thermal properties.

Cost Considerations and Availability

Fused silica typically commands a higher price due to its superior thermal and optical properties, whereas aluminosilicate glass offers a more cost-effective alternative with good mechanical strength and chemical resistance. Availability of fused silica is more limited, as it requires specialized manufacturing processes, while aluminosilicate is more widely produced and readily accessible in various commercial applications. Cost considerations often lead industries to choose aluminosilicate when budget constraints outweigh the need for the exceptional performance of fused silica.

Manufacturing Processes and Techniques

Fused silica is produced through the melting and rapid cooling of high-purity quartz crystals, resulting in a non-crystalline structure ideal for high-temperature and optical applications. Aluminosilicate glass is manufactured via a melting process that incorporates aluminum oxide into the silica matrix, enhancing strength and heat resistance with a partially crystalline structure. Techniques such as flame fusion or chemical vapor deposition are employed for fused silica, while aluminosilicate production commonly uses fusion melting followed by precision annealing to optimize durability.

Environmental Stability and Lifespan

Fused silica exhibits exceptional environmental stability due to its low thermal expansion coefficient and high resistance to chemical corrosion, making it ideal for harsh conditions and prolonged use. Aluminosilicate glass offers enhanced mechanical strength and improved resistance to thermal shock but may exhibit slightly lower chemical durability compared to fused silica. Lifespan of fused silica tends to outperform aluminosilicate in extreme environments, ensuring longer-lasting optical and structural performance.

Choosing the Right Material: Key Factors

Fused silica offers exceptional thermal stability and high chemical resistance, making it ideal for high-temperature and precision optical applications, while aluminosilicate glass provides superior mechanical strength and impact resistance, suitable for durable protective covers and consumer electronics screens. Consider factors such as operating temperature range, mechanical stress requirements, and chemical exposure to determine the optimal glass type. Selecting the right material directly affects performance, longevity, and cost-efficiency in applications ranging from laboratory equipment to smartphone displays.

Fused Silica vs Aluminosilicate Infographic

materialdif.com

materialdif.com