Ceramic glass offers superior heat resistance and durability compared to acrylic glass, making it ideal for high-temperature applications such as oven doors and fireplace screens. Acrylic glass, also known as PMMA, is lighter and more impact-resistant but is prone to scratching and can deform under high heat. Choosing between ceramic and acrylic glass depends on the specific needs for thermal endurance, strength, and clarity in your project.

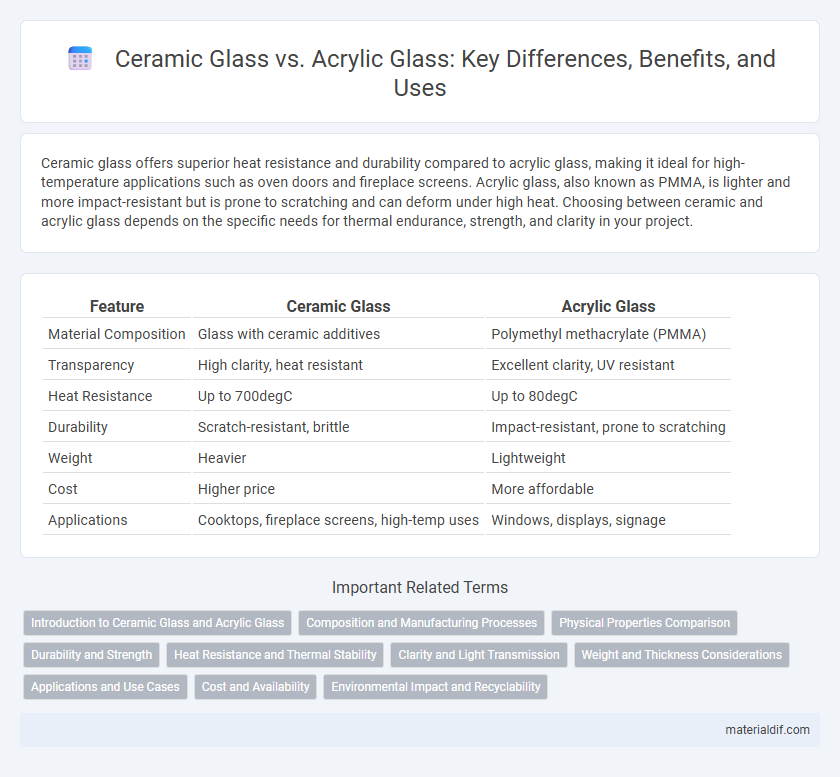

Table of Comparison

| Feature | Ceramic Glass | Acrylic Glass |

|---|---|---|

| Material Composition | Glass with ceramic additives | Polymethyl methacrylate (PMMA) |

| Transparency | High clarity, heat resistant | Excellent clarity, UV resistant |

| Heat Resistance | Up to 700degC | Up to 80degC |

| Durability | Scratch-resistant, brittle | Impact-resistant, prone to scratching |

| Weight | Heavier | Lightweight |

| Cost | Higher price | More affordable |

| Applications | Cooktops, fireplace screens, high-temp uses | Windows, displays, signage |

Introduction to Ceramic Glass and Acrylic Glass

Ceramic glass is a durable, heat-resistant material commonly used in cooktops and fireplaces, characterized by its ability to withstand high temperatures without deforming or cracking. Acrylic glass, also known as plexiglass, is a lightweight, shatter-resistant alternative to traditional glass often used in windows and displays due to its clarity and impact resistance. Both materials offer unique advantages, with ceramic glass providing thermal stability and acrylic glass excelling in flexibility and lightweight properties.

Composition and Manufacturing Processes

Ceramic glass is composed of crystalline materials such as alumina and silica, produced through a high-temperature vitrification process that results in exceptional heat resistance and durability. Acrylic glass, or polymethyl methacrylate (PMMA), is a synthetic polymer created via polymerization of methyl methacrylate monomers, offering lightweight and impact-resistant properties but lower heat resistance. The manufacturing of ceramic glass involves controlled cooling and annealing to ensure structural integrity, while acrylic glass is typically cast or extruded, allowing for versatility in shaping and finishing.

Physical Properties Comparison

Ceramic glass exhibits exceptional thermal resistance, withstanding temperatures up to 1400degC, unlike acrylic glass, which softens around 160degC. The hardness of ceramic glass rates higher on the Mohs scale, providing superior scratch resistance compared to the softer acrylic material. Acrylic glass offers greater impact resistance and flexibility, making it less prone to shattering than the brittle ceramic glass.

Durability and Strength

Ceramic glass exhibits exceptional durability and high thermal resistance, making it ideal for environments exposed to intense heat and mechanical stress. Acrylic glass, while lighter and more impact-resistant, lacks the heat resistance and scratch hardness of ceramic glass, resulting in lower long-term durability under harsh conditions. For applications demanding maximum strength and heat endurance, ceramic glass outperforms acrylic glass significantly.

Heat Resistance and Thermal Stability

Ceramic glass offers superior heat resistance and thermal stability, maintaining structural integrity at temperatures exceeding 700degC, making it ideal for high-heat applications like stovetops and fireplaces. Acrylic glass, while lightweight and impact-resistant, typically withstands temperatures only up to 80degC before deforming or melting. The thermal performance of ceramic glass ensures durability and safety in environments with rapid temperature fluctuations, unlike acrylic glass which is prone to thermal expansion and warping under heat stress.

Clarity and Light Transmission

Ceramic glass offers superior clarity and light transmission compared to acrylic glass, with a transmittance rate often exceeding 90%, allowing more natural light to pass through without distortion. Acrylic glass typically has lower light transmission, around 92%, but can be prone to yellowing and scratches that reduce clarity over time. The chemical stability and hardness of ceramic glass ensure long-lasting optical performance, making it ideal for applications requiring precise visual clarity.

Weight and Thickness Considerations

Ceramic glass typically weighs more and offers higher thickness options, making it ideal for applications requiring exceptional heat resistance and durability. Acrylic glass is significantly lighter and thinner, providing easier handling and installation but with less thermal tolerance. Choosing between the two depends on the specific weight constraints and thickness needs of the project.

Applications and Use Cases

Ceramic glass offers high heat resistance and durability, making it ideal for applications such as stovetops, fireplace doors, and laboratory equipment where thermal stability is crucial. Acrylic glass, known for its lightweight and impact resistance, is preferred in signage, displays, and protective barriers where transparency and ease of fabrication are essential. Both materials serve distinct purposes in architectural, industrial, and consumer product domains based on their mechanical and thermal properties.

Cost and Availability

Ceramic glass typically costs more than acrylic glass due to its high heat resistance and durability, making it ideal for specialized applications such as stove tops and fireplace doors. Acrylic glass is widely available and more affordable, often used for picture frames, windows, and signage because of its lightweight and impact-resistant properties. The cost difference reflects the manufacturing processes and material performance, influencing availability in various markets.

Environmental Impact and Recyclability

Ceramic glass exhibits superior environmental benefits due to its longer lifespan and resistance to thermal shock, reducing the frequency of replacement and waste generation. Its recyclability is limited but involves specialized processes that recover raw materials with minimal environmental footprint. Acrylic glass, while lightweight and easy to shape, poses greater environmental challenges due to its petroleum-based origin and difficulties in recycling, often resulting in higher landfill contributions.

Ceramic Glass vs Acrylic Glass Infographic

materialdif.com

materialdif.com