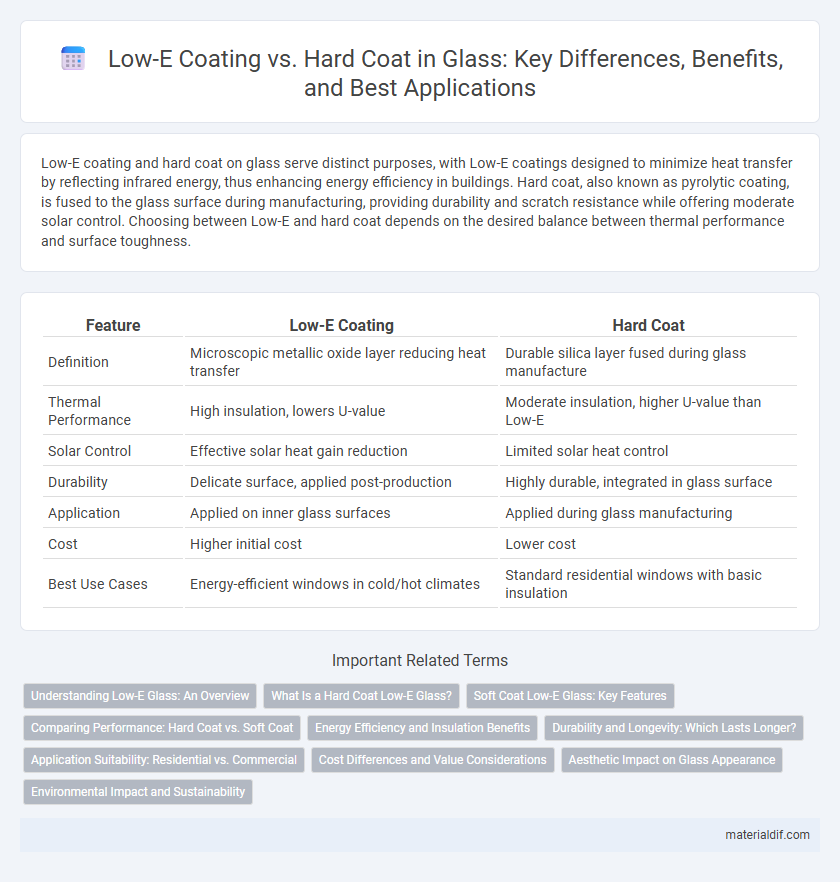

Low-E coating and hard coat on glass serve distinct purposes, with Low-E coatings designed to minimize heat transfer by reflecting infrared energy, thus enhancing energy efficiency in buildings. Hard coat, also known as pyrolytic coating, is fused to the glass surface during manufacturing, providing durability and scratch resistance while offering moderate solar control. Choosing between Low-E and hard coat depends on the desired balance between thermal performance and surface toughness.

Table of Comparison

| Feature | Low-E Coating | Hard Coat |

|---|---|---|

| Definition | Microscopic metallic oxide layer reducing heat transfer | Durable silica layer fused during glass manufacture |

| Thermal Performance | High insulation, lowers U-value | Moderate insulation, higher U-value than Low-E |

| Solar Control | Effective solar heat gain reduction | Limited solar heat control |

| Durability | Delicate surface, applied post-production | Highly durable, integrated in glass surface |

| Application | Applied on inner glass surfaces | Applied during glass manufacturing |

| Cost | Higher initial cost | Lower cost |

| Best Use Cases | Energy-efficient windows in cold/hot climates | Standard residential windows with basic insulation |

Understanding Low-E Glass: An Overview

Low-E glass features a microscopically thin metal oxide coating that enhances energy efficiency by reflecting infrared heat while allowing visible light to pass through, reducing heating and cooling costs. Hard coat Low-E glass, also known as pyrolytic coating, is applied during the glass manufacturing process, resulting in a durable surface that withstands abrasion and is ideal for single-pane applications. Understanding the differences between soft coat and hard coat Low-E glasses is crucial for selecting the appropriate glazing solution based on climate, building design, and energy performance requirements.

What Is a Hard Coat Low-E Glass?

Hard coat Low-E glass features a durable, transparent metal oxide coating applied during the glass manufacturing process, enhancing solar control by reflecting infrared radiation while allowing visible light to pass through. This coating is thermally bonded to the glass surface, increasing scratch resistance compared to soft coat Low-E glass, making it ideal for single-pane applications and high-exposure environments. Its energy-efficient properties help reduce heating and cooling costs by minimizing heat transfer and improving indoor comfort.

Soft Coat Low-E Glass: Key Features

Soft Coat Low-E glass features a thin metallic layer that offers superior thermal insulation by reflecting infrared energy while allowing visible light to pass through. This coating provides excellent energy efficiency with a lower U-value, reducing heating and cooling costs significantly. Compared to Hard Coat, Soft Coat Low-E glass delivers enhanced performance in controlling solar heat gain and improving overall indoor comfort.

Comparing Performance: Hard Coat vs. Soft Coat

Low-E coatings significantly outperform hard coats in thermal insulation by reflecting infrared radiation while allowing visible light transmission, reducing energy loss in buildings. Hard coats, typically created through chemical vapor deposition, offer superior durability and scratch resistance but provide less effective solar control compared to soft coat Low-E coatings applied via sputtering methods. Soft coat Low-E glasses demonstrate higher emissivity reduction and better overall energy efficiency, making them preferable for applications requiring optimized thermal performance.

Energy Efficiency and Insulation Benefits

Low-E coating significantly enhances energy efficiency by reflecting infrared heat, reducing heat transfer through glass, and maintaining indoor temperature stability, which lowers heating and cooling costs. Hard coat technology improves insulation by providing a durable, scratch-resistant surface that also reduces solar heat gain, contributing to better thermal performance. Both coatings optimize glass functionality, but Low-E coatings offer superior benefits for energy savings and temperature regulation.

Durability and Longevity: Which Lasts Longer?

Low-E coatings typically offer enhanced durability due to their multi-layered metal oxide composition, providing superior resistance to environmental wear and maintaining thermal performance over time. Hard coat glass, while mechanically bonded during the glass tempering process, is more prone to surface scratches and degradation under harsh conditions. Studies show Low-E coatings generally last longer than hard coat glass, especially in exterior applications exposed to weathering and UV radiation.

Application Suitability: Residential vs. Commercial

Low-E coating excels in residential applications by enhancing energy efficiency through superior thermal insulation and solar control, reducing heating and cooling costs. In contrast, Hard coat glass is more suitable for commercial settings where durability and abrasion resistance are critical due to higher traffic and maintenance demands. Both coatings improve glass performance, but Low-E is favored for residential comfort, while Hard coat meets the rigorous requirements of commercial environments.

Cost Differences and Value Considerations

Low-E coating typically costs more than hard coat due to advanced technology that enhances thermal insulation and energy savings. Hard coat offers a more affordable option but provides less effective solar control and durability under harsh weather conditions. Evaluating the long-term energy savings and climate-specific benefits often justifies the higher initial investment in Low-E coatings.

Aesthetic Impact on Glass Appearance

Low-E coating enhances glass by reducing glare and offering a subtle reflective quality, maintaining clarity while improving energy efficiency. Hard coat creates a more durable surface with a slightly matte finish, which can soften the glass's transparency and alter its visual sharpness. Both coatings influence the glass's appearance differently, with Low-E providing a cleaner, more modern aesthetic compared to the textured look of Hard coat.

Environmental Impact and Sustainability

Low-E coatings significantly reduce energy consumption by minimizing heat transfer through glass, leading to lower carbon emissions and improved building energy efficiency. Hard coat glass provides durability and resistance but typically lacks the same level of thermal performance, resulting in higher energy use over time. Incorporating Low-E coatings supports sustainable building practices by lowering heating and cooling demands, thus reducing environmental impact compared to standard hard coat glass.

Low-E coating vs Hard coat Infographic

materialdif.com

materialdif.com