Optical glass is engineered with precise refractive properties and minimal impurities to enhance clarity and light transmission in lenses and instruments, whereas window glass prioritizes durability, weather resistance, and cost-effectiveness for building applications. Optical glass often undergoes specialized manufacturing processes to achieve specific optical performance criteria, while window glass is typically produced in larger, thinner sheets designed to withstand environmental stress. The distinct compositions and treatments result in optical glass offering superior image quality and light control compared to the more utilitarian characteristics of window glass.

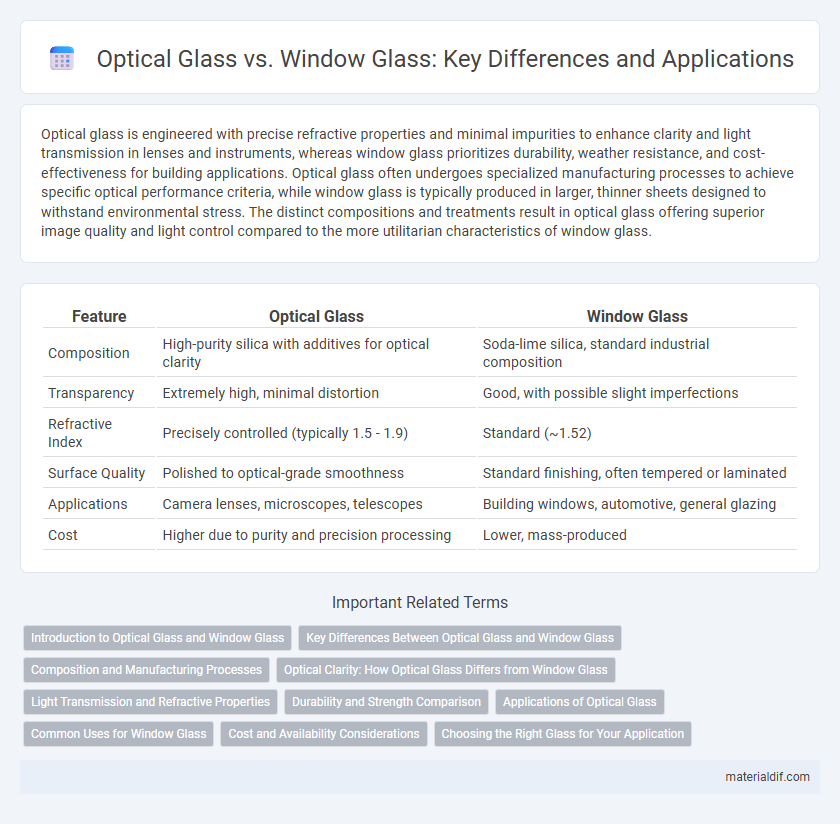

Table of Comparison

| Feature | Optical Glass | Window Glass |

|---|---|---|

| Composition | High-purity silica with additives for optical clarity | Soda-lime silica, standard industrial composition |

| Transparency | Extremely high, minimal distortion | Good, with possible slight imperfections |

| Refractive Index | Precisely controlled (typically 1.5 - 1.9) | Standard (~1.52) |

| Surface Quality | Polished to optical-grade smoothness | Standard finishing, often tempered or laminated |

| Applications | Camera lenses, microscopes, telescopes | Building windows, automotive, general glazing |

| Cost | Higher due to purity and precision processing | Lower, mass-produced |

Introduction to Optical Glass and Window Glass

Optical glass is specially formulated with precise refractive indices and low dispersion to enhance image clarity in lenses, microscopes, and cameras, differing significantly from window glass which prioritizes transparency and strength for architectural applications. Window glass, typically soda-lime silica glass, is designed for large-scale production with durability and cost-effectiveness, while optical glass undergoes rigorous quality control for purity and uniformity to avoid distortions. Understanding these distinctions is critical in selecting the appropriate glass type for specific industrial or consumer needs.

Key Differences Between Optical Glass and Window Glass

Optical glass exhibits superior clarity, higher refractive index, and precise light transmission characteristics essential for lenses, microscopes, and cameras, whereas window glass prioritizes durability, cost-effectiveness, and weather resistance with lower optical quality. Optical glass often contains specific additives like rare earth elements to reduce chromatic aberration, while window glass typically uses soda-lime silica composition designed for strength and thermal insulation. The manufacturing process for optical glass involves meticulous control over homogeneity and impurities, contrasting with the mass production techniques of window glass intended for architectural and automotive applications.

Composition and Manufacturing Processes

Optical glass is primarily composed of high-purity silica mixed with controlled amounts of metal oxides like boron, lead, and potassium to achieve precise refractive indices and minimal impurities, whereas window glass typically contains soda-lime-silica with added alkali metals for cost efficiency and durability. Manufacturing optical glass involves meticulous melting, homogenization, and slow cooling to prevent stress and ensure uniform optical properties; in contrast, window glass is commonly produced through float glass processes with rapid cooling designed for strength and clarity rather than optical precision. The controlled chemical composition and specialized manufacturing techniques of optical glass result in superior light transmission and minimal distortion compared to the broader tolerance and simpler production methods of standard window glass.

Optical Clarity: How Optical Glass Differs from Window Glass

Optical glass offers superior optical clarity compared to window glass due to its high purity and precise manufacturing processes, minimizing distortions and aberrations. Specialized optical glasses have controlled refractive indices and low birefringence, ensuring accurate light transmission for applications in lenses, microscopes, and cameras. In contrast, window glass, typically made from soda-lime silica, prioritizes durability and cost-effectiveness over optical precision, leading to lower clarity and increased light scattering.

Light Transmission and Refractive Properties

Optical glass exhibits superior light transmission rates, typically exceeding 90%, due to its high purity and controlled composition, making it ideal for lenses and precision instruments. Window glass, often composed of soda-lime silica, has lower light transmission and higher refractive indices, resulting in more reflection and minor color distortion. The refractive index of optical glass commonly ranges between 1.5 and 1.9, enabling precise light bending, whereas window glass typically has a refractive index around 1.52, optimizing clarity but not precision.

Durability and Strength Comparison

Optical glass is engineered with precise chemical compositions and thermal treatments to achieve high durability and strength, making it resistant to scratches and impact. Window glass, typically soda-lime glass, offers lower tensile strength and is more prone to damage from environmental stressors and physical impact. The superior hardness and structural integrity of optical glass make it ideal for lenses and precision instruments, whereas window glass prioritizes cost-effectiveness and transparency for architectural use.

Applications of Optical Glass

Optical glass is designed with precise refractive indices and low dispersion, making it essential for lenses, microscopes, cameras, and telescopes where light manipulation is critical. Unlike window glass, which prioritizes durability and transparency for construction and automotive uses, optical glass must maintain high optical clarity and minimal distortion to enhance imaging quality. Its specialized formulations enable applications in fiber optics, laser systems, and precision instruments requiring accurate light transmission and control.

Common Uses for Window Glass

Window glass, primarily made from soda-lime silica, is engineered for clarity, strength, and affordability in architectural applications. It is commonly used in residential and commercial buildings to provide natural light, thermal insulation, and sound control. Unlike optical glass, window glass does not require the high precision or special refractive properties needed for lenses or scientific instruments.

Cost and Availability Considerations

Optical glass, known for its high refractive index and purity, is significantly more expensive and less readily available than window glass due to specialized manufacturing processes. Window glass is mass-produced, making it widely accessible and cost-effective for construction and everyday applications. Budget constraints and project requirements often dictate the choice between optical glass and window glass based on cost efficiency and availability.

Choosing the Right Glass for Your Application

Optical glass offers high clarity, precise light transmission, and minimal distortion, making it ideal for lenses, cameras, and scientific instruments. Window glass prioritizes durability, weather resistance, and cost-effectiveness, suitable for building facades and residential windows. Selecting the right glass depends on application-specific factors such as optical performance, strength requirements, and environmental exposure.

Optical glass vs Window glass Infographic

materialdif.com

materialdif.com